Mitsubishi Lancer Evolution VI. Manual - part 113

HEATER AND MANUAL AIR CONDITIONER –

Troubleshooting

55-4

TROUBLESHOOTING

TROUBLESHOOTING PROCEDURES

1.

Check air ducts, control rods, etc. for improper connection.

2.

Check that the electrical connectors of the relevant components are connected securely and the

fuse is not blown.

3.

Perform the troubleshooting as follows; first understand the items to be inspected and the the procedures

comprehensively using Trouble Symptom/Failed Component Cross-Reference Table and then inspect

the appropriate items sequentially.

4.

Be sure to perform each component check after disconnecting the relevant connector.

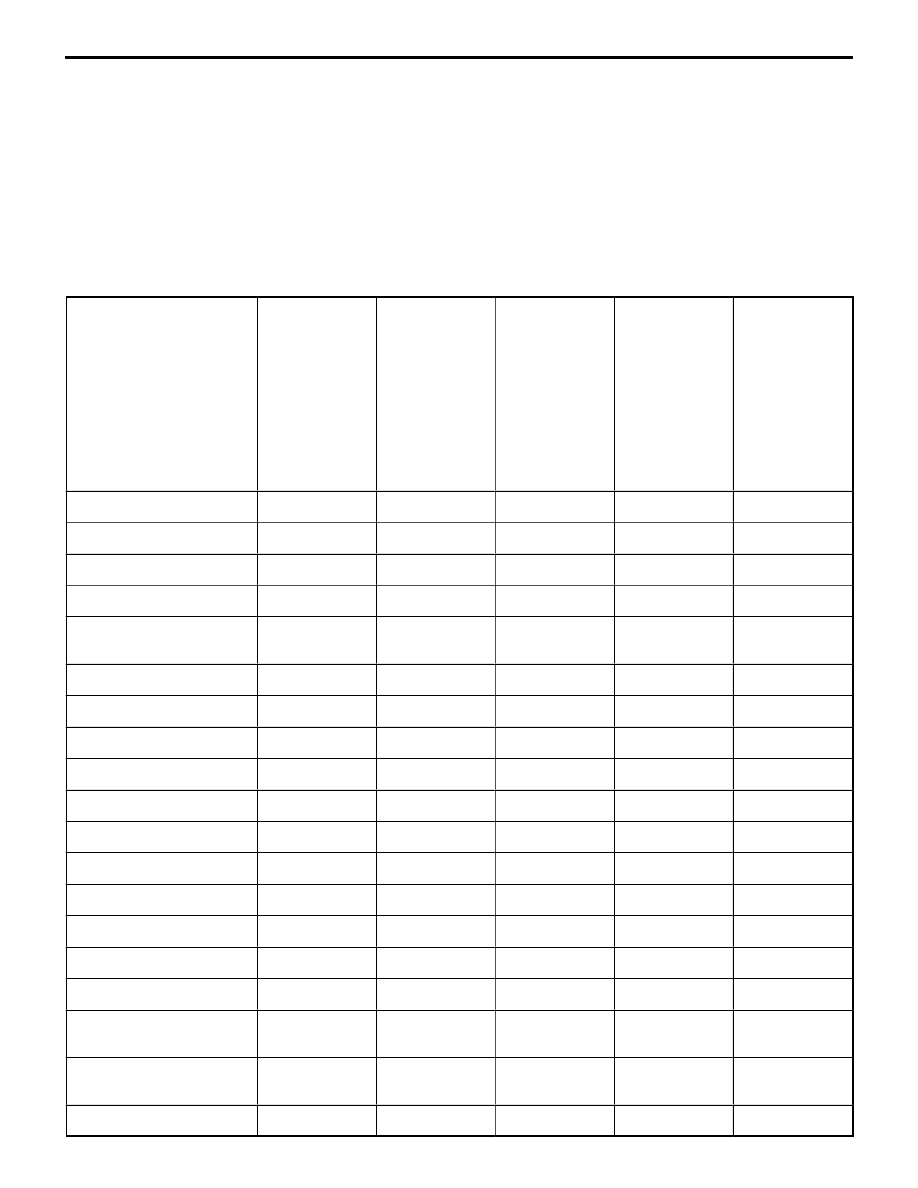

Trouble Symptom/Failed Component Cross-Reference Table

Items to be checked

1.

When the igni-

tion switch is

“ON”, the A/C

does not oper-

ate.

2.

When the A/C

is operating,

temperature

inside the pas-

senger

compartment

does not

decrease (cool

air is not

emitted).

3.

Blower fan

motor does not

turn.

4.

Blower fan

motor does not

stop turning.

5.

When A/C is

operating,

radiator fan

and condenser

fan do not run.

Fuse

1

1

1

Harness, connector

2

2

1

2

Amount of refrigerant

3

1

A/C compressor relay

4

A/C compressor magnet

clutch

5

Dual pressure switch

6

2

3

A/C switch

7

Blower switch

8

3

2

Blower relay

4

Resistor

5

3

Blower motor

6

Air thermo-sensor

9

3

Condenser fan relay

4

4

Condenser fan motor

5

5

Radiator fan relay (HI, LO)

6

6

Radiator fan motor

7

7

Refrigerant temperature

switch

10

8

Auto compressor control

unit

11

9

Engine-ECU

12

10

8