Mitsubishi Lancer Evolution VI. Manual - part 81

STEERING –

Power Steering Gear Box

37A-16

2.

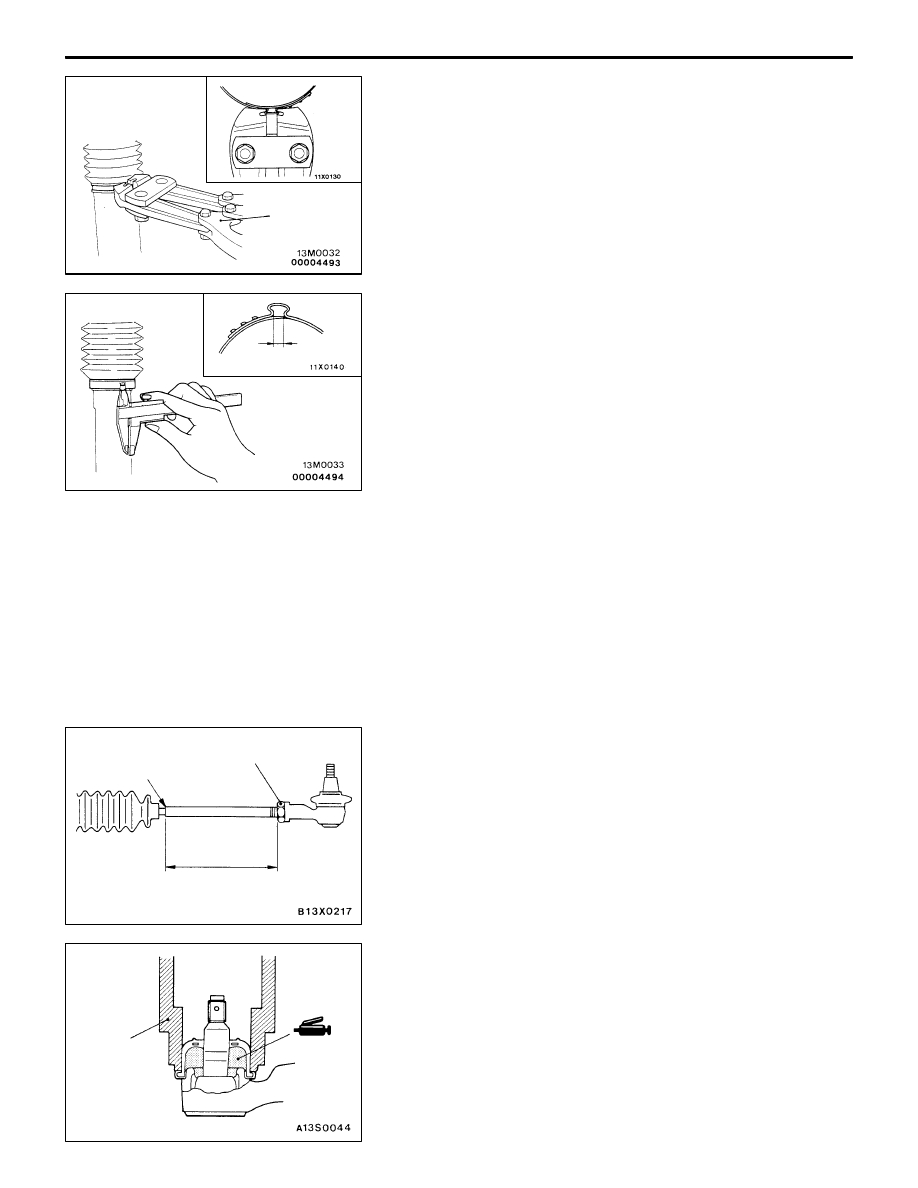

Use the special tool to crimp the bellows band.

Caution

(1) Hold the rack housing, and use the special tool

to crimp the bellows band securely.

(2) Crimp the bellows band until the special tool

touches the stopper.

3.

Check that the crimped width (A) is within the standard

value.

Standard value (A): 2.4 – 2.8 mm

<When more than 2.8 mm>

Readjust the dimension (W) of step (1) to the value

calculated by the following equation, and repeat

step (2).

W = 5.5 mm – A [Example: If (A) is 2.9 mm, (W)

is 2.6 mm.]

<When less than 2.4 mm>

Remove the bellows band, readjust the dimension

(W) of step (1) to the value calculated by the

following equation, and use a new bellows band

to repeat steps (2) to (3).

W = 5.5 mm – A [Example: If (A) is 2.3 mm, (W)

is 3.2 mm.]

"

N

A

TIE-ROD END / TIE-ROD END LOCKING NUT

INSTALLATION

Screw in the tie-rod end until the dimension shown is achieved.

Then, temporarily tighten with the locking nut.

NOTE

The locking nut must be tightened securely only after the

power steering gear box and linkage are installed to the vehicle

and toe-in is adjusted.

TIE-ROD END BALL JOINT DUST COVER

REPLACEMENT

Only when the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1.

Apply grease inside a new dust cover.

2.

Using the special tool, press in the dust cover to the

tie rod end.

3.

Check the dust cover for cracks or damage by pushing

it with finger.

MB991561

A

212 mm

Edge of bellows

assembly groove

Lock nut

MB990776