Mitsubishi Lancer Evolution VI. Manual - part 80

STEERING –

Power Steering Gear Box

37A-12

REASSEMBLY SERVICE POINTS

"

A

A

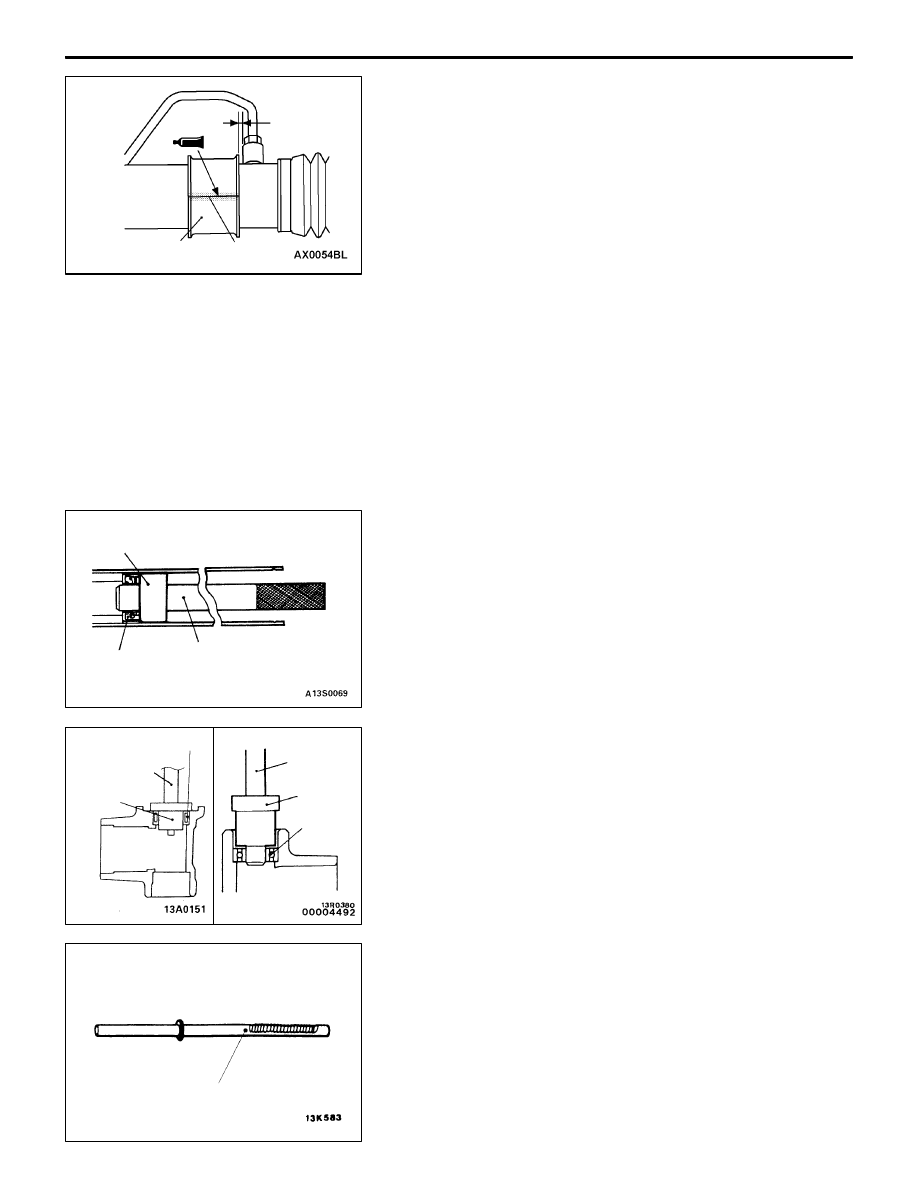

GEAR HOUSING MOUNTING RUBBER

INSTALLATION

1.

Install the gear housing mounting rubber on the rack

housing so that the dimension shown is achieved.

NOTE

The gear housing mounting rubber can be installed

regardless of the installation direction of the slit.

2.

Apply specified adhesive to the slit of the gear housing

mounting rubber.

Specified adhesive:

3M ATD Part No. 8155 or equivalent

"

B

A

OIL SEAL INSTALLATION

"

C

A

NEEDLE ROLLER BEARING / BALL BEARING

INSTALLATION

"

D

A

RACK INSTALLATION

1.

Apply a coating of repair kit grease to the rack tooth

face.

Caution

Do not close the vent hole in the rack with grease.

Slit

Gear housing

mounting rubber

3.1 mm

MB991452

Oil seal

MB991197

(Bar)

Needle roller

bearing

MB990938

MB991202

MB990938

MB991202

Ball bearing

Vent hole