Mitsubishi Lancer Evolution VI. Manual - part 16

ENGINE –

Rocker Arms and Camshaft

11-39

"

D

A

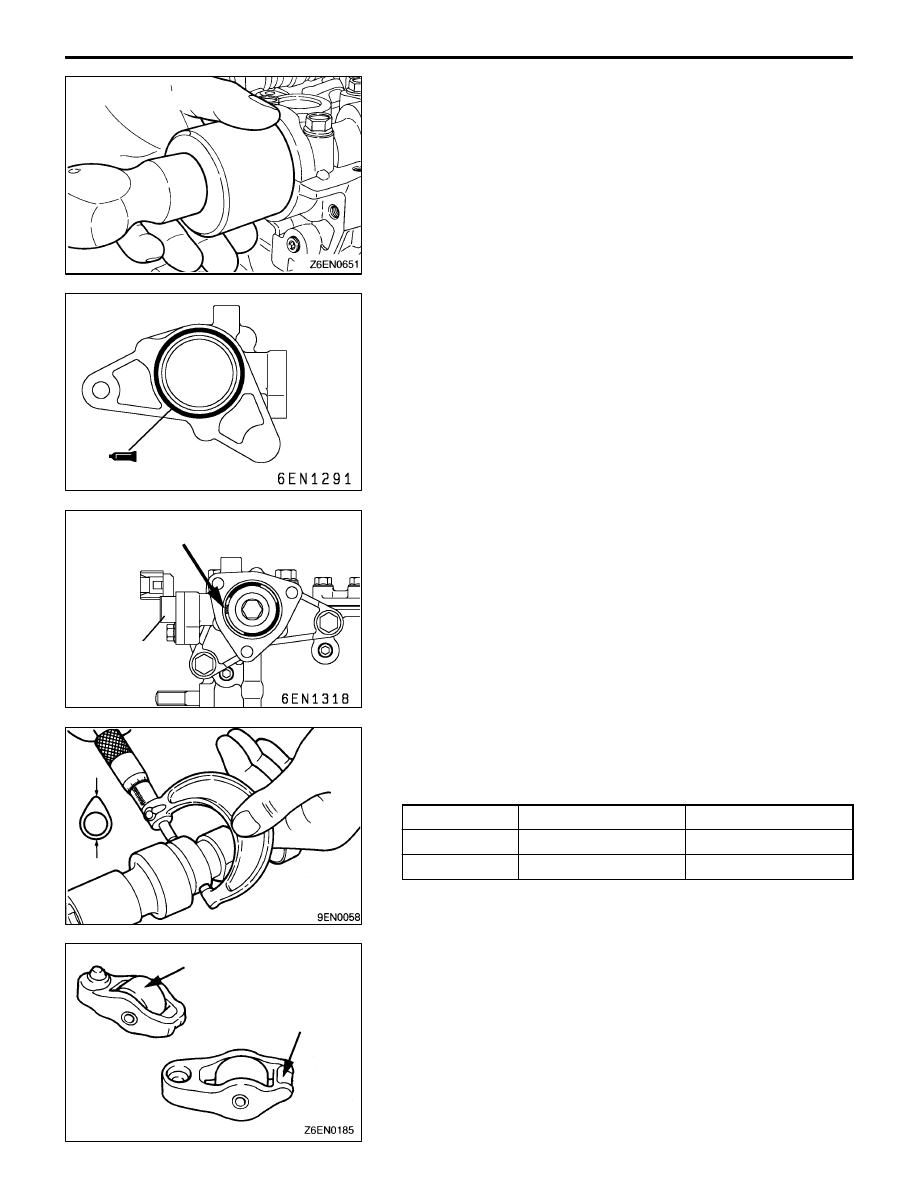

CAMSHAFT OIL SEAL INSTALLATION

(1) Apply engine oil to lib area of the oil seal and the front

end outside diameter of the camshaft.

(2) Using special tool install the camshaft oil seals.

"

E

A

CAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

Apply 3 mm diameter of form-in-place gasket (FIPG) to the

location shown in the illustration.

Specified sealant:

Mitsubishi Genuine Part No. MD970389 or equivalent

"

F

A

CAMSHAFT POSITION SENSING CYLINDER

INSTALLATION

(1) Set the No. 1 cylinder to the compression top dead center

position (so that dowel pin of the exhaust camshaft is

at the top).

(2) Install the camshaft position sensing cylinder so that the

white paint mark is facing in the direction shown in the

illustration.

INSPECTION

CAMSHAFT

Measure the cam height.

Item

Standard value mm

Limit mm

Intake

35.79

35.29

Exhaust

35.49

34.99

ROCKER ARM

(1) Check the roller surface. If any dents, damage or seizure

is evident, replace the rocker arm.

(2) Check rotation of the roller. If it does not rotate smoothly

or if looseness is evident, replace the rocker arm.

(3) Check the inside diameter. If damage or seizure is evident,

replace the rocker arm.

MD998713

Camshaft

position

sensor

Paint mark

Roller

Tip