Mitsubishi Lancer Evolution VI. Manual - part 17

ENGINE –

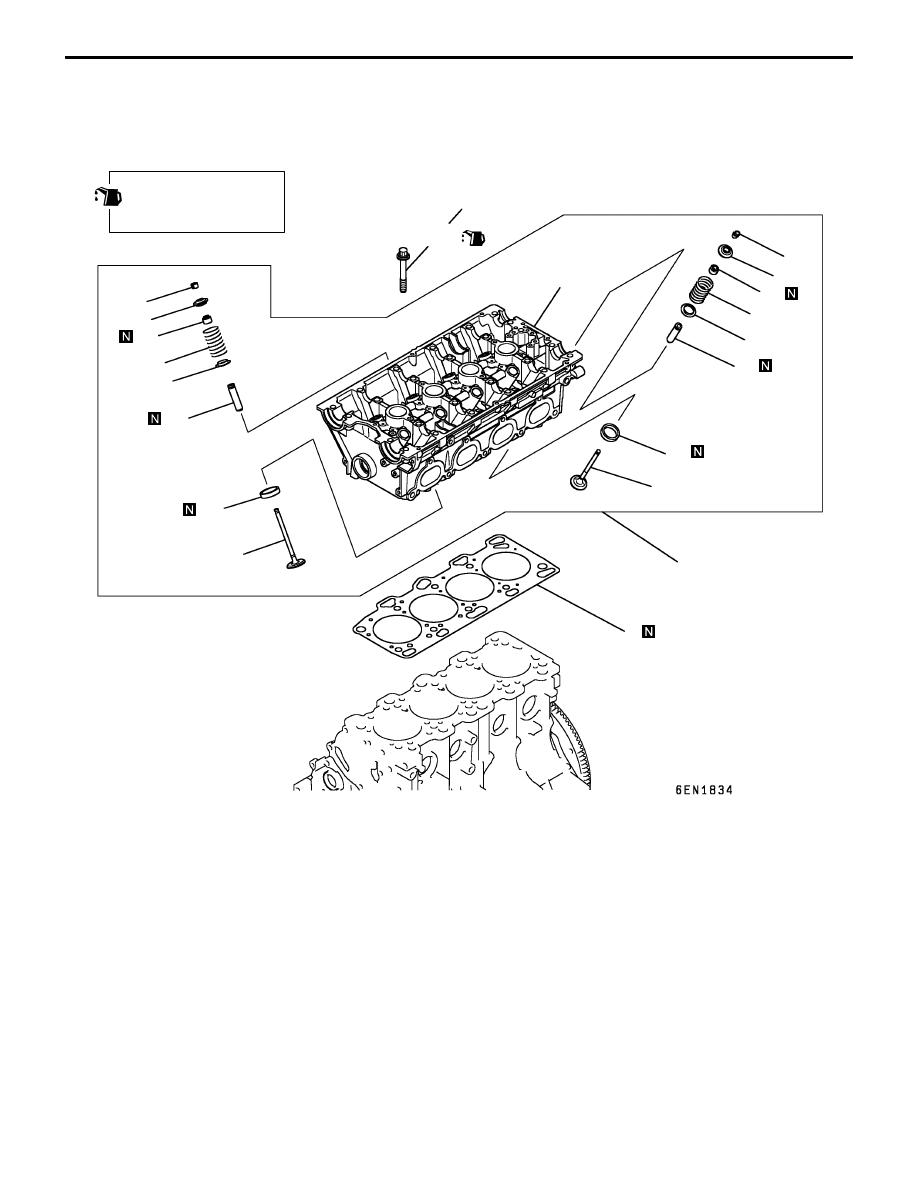

Cylinder Head and Valves

11-43

CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION

Apply engine oil to all

moving parts before

installation.

78 Nm

→

Loosen completely

→

20 Nm + 90

_

+ 90

_

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Removal steps

A

A

" "

D

A

1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

A

B

" "

C

A

4. Retainer lock

5. Valve spring retainer

"

B

A

6. Valve spring

7. Intake valve

A

B

" "

C

A

8. Retainer lock

9. Valve spring retainer

"

B

A

10. Valve spring

A

C

"

11. Exhaust valve

"

A

A

12. Valve stem seal

13. Valve spring seat

"

A

A

14. Valve stem seal

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head