Mitsubishi Lancer Evolution VI. Manual - part 15

ENGINE –

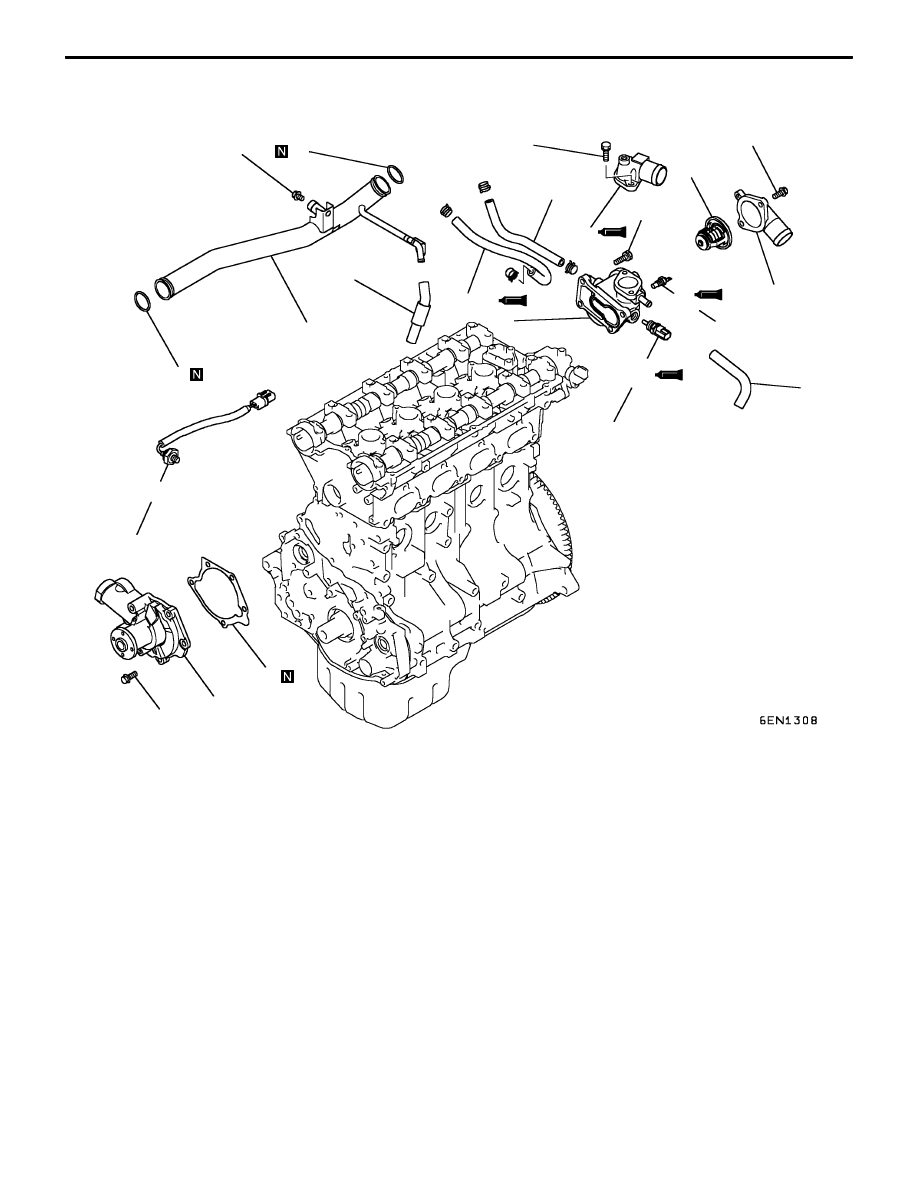

Water Pump and Water Hose

11-35

REMOVAL AND INSTALLATION <EVOLUTION IV or V>

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

14 Nm

22 Nm

11 Nm

24 Nm

24 Nm

29 Nm

13 Nm

10

13 Nm

Removal steps

1. Water hose

2. Water hose

3. Water hose

4. Water hose

"

E

A

5. Water temperature sensor

"

D

A

6. Water temperature gauge unit

7. Water inlet fitting

8. Thermostat

"

C

A

9. Water outlet fitting

"

B

A

10. Thermostat housing

"

A

A

11. O-ring

"

A

A

12. Water inlet pipe

"

A

A

13. O-ring

14. Water pump

15. Water pump gasket

16. Knock sensor