Mitsubishi Eclipse. Manual - part 863

ROCKER ARMS AND CAMSHAFT

TSB Revision

ENGINE OVERHAUL <2.4L>

11B-29

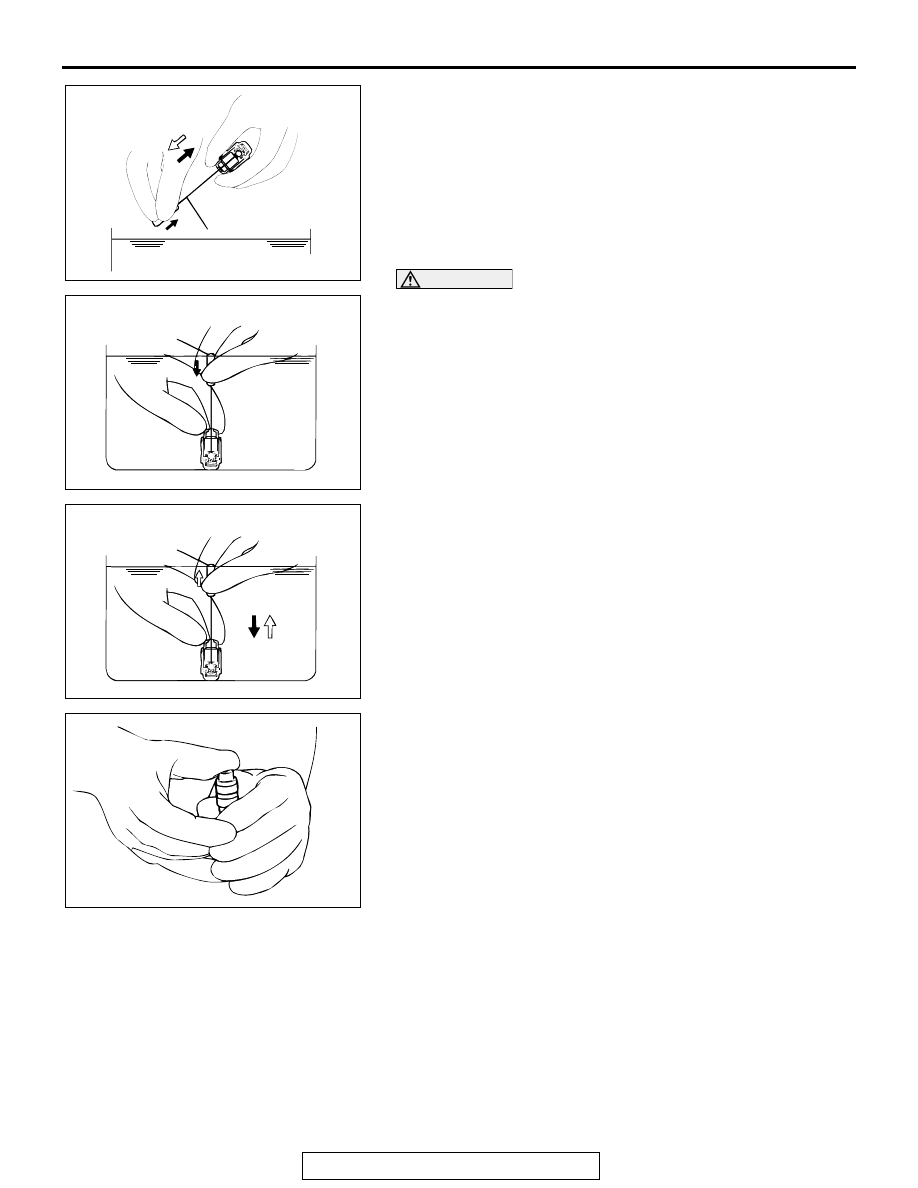

6. Remove the lash adjuster from the container. Then, push

down the steel ball gently and push the plunger to eliminate

diesel fuel from the pressure chamber.

CAUTION

Do not use container C for cleaning. If cleaning is per-

formed in container C, foreign matter could enter the pres-

sure chamber when the chamber is filled with diesel fuel.

7. Place the lash adjuster in container C. Then, gently push

down the internal steel ball using wire [0.5 mm (0.020 inch)

in diameter] or special tool MD998442.

8. Stand the lash adjuster with its plunger at the top, then push

the plunger downward firmly until it moves through its

greatest possible stroke. Return the plunger slowly, then

release the steel ball and allow the pressure chamber to fill

with diesel fuel.

9. Remove the lash adjuster from the container, then stand the

lash adjuster with its plunger at the top. Push the plunger

firmly and check that it does not move. Also, check that the

lash adjuster's height matches that of a new lash adjuster.

NOTE: If the lash adjuster contracts or moves, perform the

operations (7) through (9) again to fill it with diesel fuel com-

pletely. Replace the lash adjuster if it still contracts or moves

after performing these steps.

10.Stand the lash adjuster upright to prevent diesel fuel from

spilling out. Do not allow the lash adjuster to become

contaminated by dirt or other foreign matter. Fit the lash

adjuster onto the engine as soon as possible.

AKX00507

WIRE OR MD998442

DIESEL FUEL

AB

AKX00508

DIESEL

FUEL

WIRE OR MD998442

AB

AKX00509

DIESEL

FUEL

WIRE OR MD998442

AB

AKX00505