Mitsubishi Eclipse. Manual - part 864

CYLINDER HEAD AND VALVES

TSB Revision

ENGINE OVERHAUL <2.4L>

11B-33

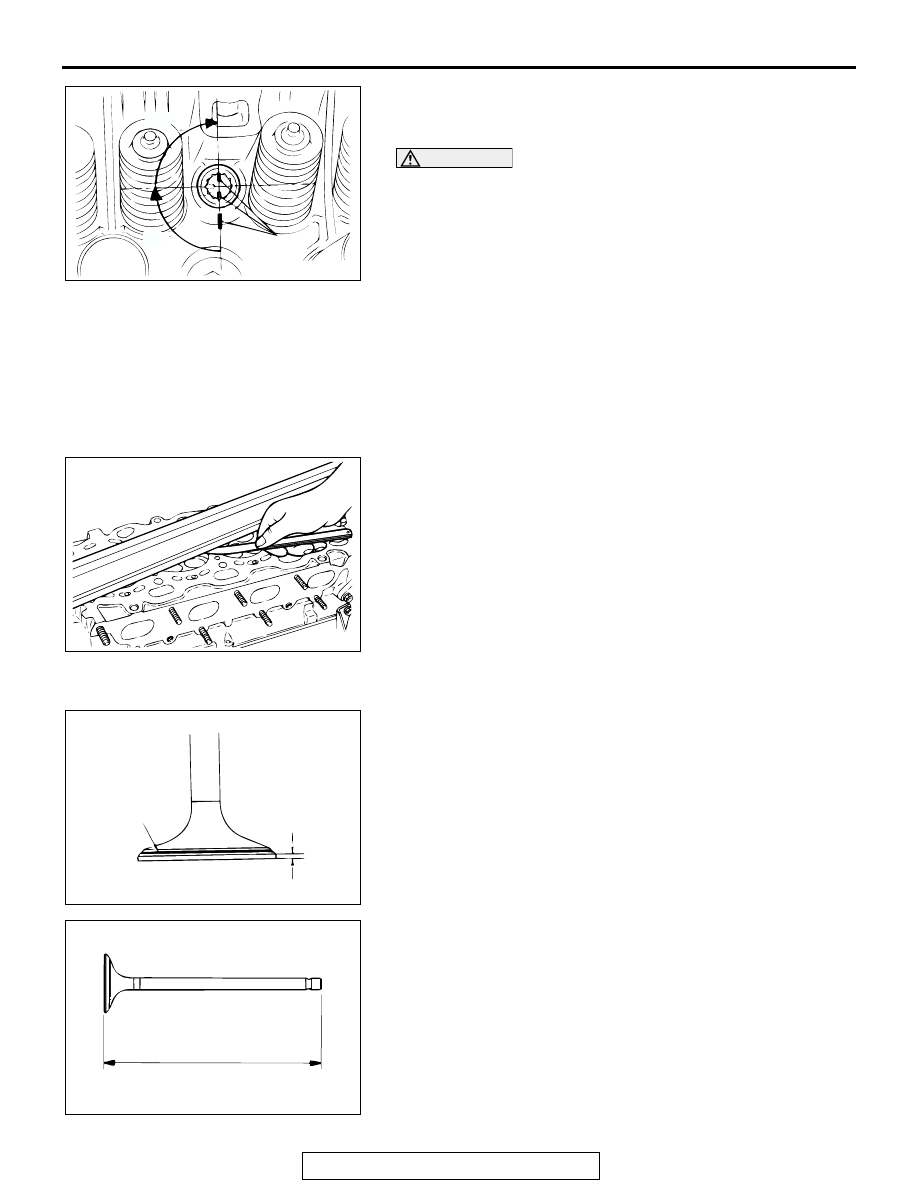

6. Make a paint mark across each bolt head and cylinder head.

7. Tighten the cylinder head bolts 90 degree angle in the

specified order.

CAUTION

• If the bolt is turned less than 90 degree angle, proper

fastening performance may not be achieved. Be careful

to turn each bolt exactly 90 degree angle.

• If the bolt is overtightened, loosen the bolt completely

and then retighten it by repeating the tightening proce-

dure from step 1.

8. Tighten the bolts another 90 degree angle in the same order

as in step 7, and check that the paint marks on the cylinder

head bolt are aligned with the paint marks on the cylinder

head.

INSPECTION

M1113007000055

.

CYLINDER HEAD

1. Check the cylinder head gasket surface for flatness by using

a straight edge and feeler gauge.

Standard value: 0.05 mm (0.002 inch)

Limit: 0.2 mm (0.007 inch)

2. If it exceeds the limit, correct to meet specification.

Grinding limit: *0.2 mm (0.007 inch)

* Includes combined with cylinder block grinding.

Cylinder head height (Specification when new):

120 mm (4.7 inches)

.

VALVE

1. Check the valve seat contact. Valve seat contact should be

uniform at the center of the valve face. If incorrect, reface

using a valve refacer.

2. If the margin is below the limit, replace the valve.

Standard value:

<Intake> 1.0 mm (0.03 inch)

<Exhaust> 1.2 mm (0.04 inch)

Minimum limit:

<Intake> 0.5 mm (0.02 inch)

<Exhaust> 0.7 mm (0.03 inch)

3. Measure the valve's total length. If the measurement is less

than the limit, replace the valve.

Standard value:

<Intake> 112.30 mm (4.421 inches)

<Exhaust> 114.11 mm (4.493 inches)

Minimum limit:

<Intake> 111.80 mm (4.402 inches)

<Exhaust> 113.61 mm (4.473 inches)

AKX00449

PAINT MARK

AB

90˚

90˚

AKX00604

AKX00455

VALVE SEAT

CONTACT

MARGIN

AB

AKX00502