Mitsubishi Eclipse. Manual - part 854

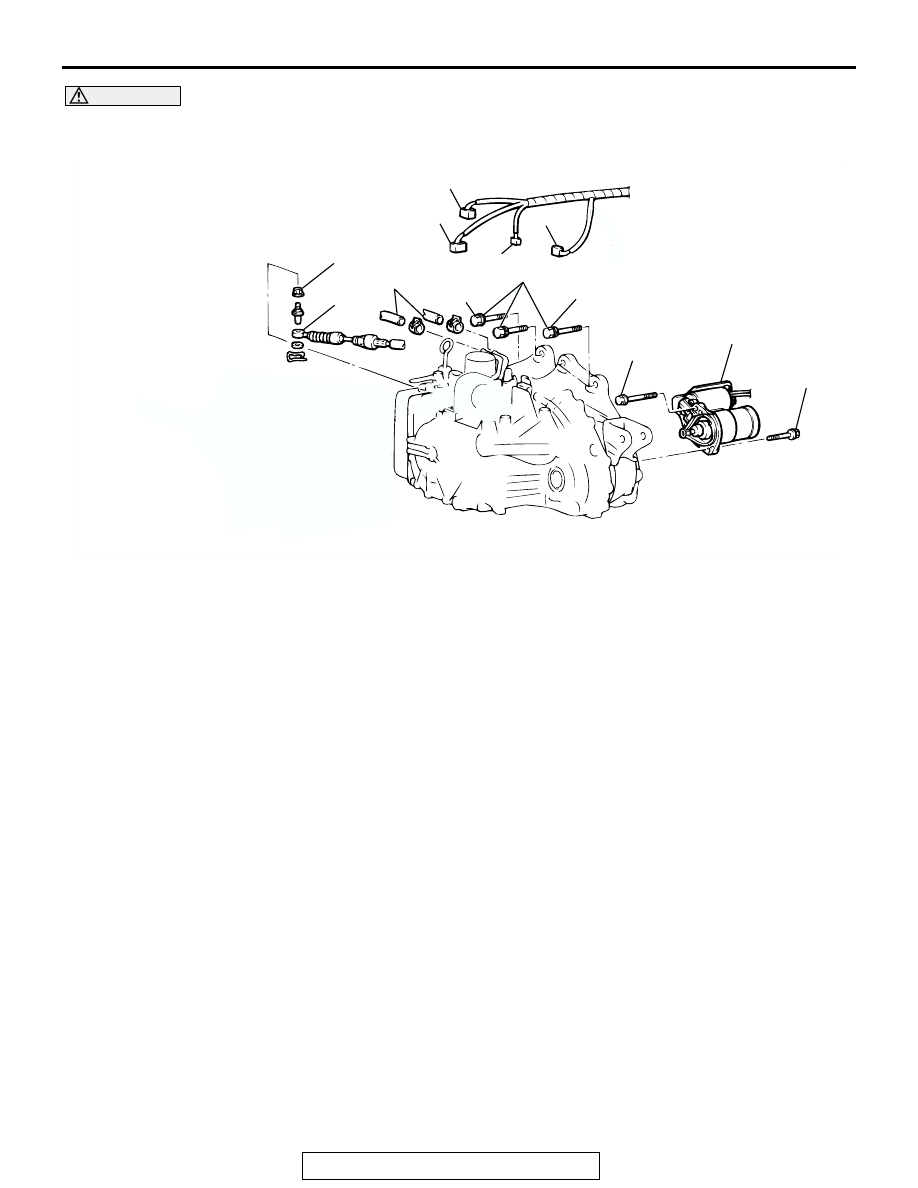

TRANSAXLE ASSEMBLY

TSB Revision

AUTOMATIC TRANSAXLE

23A-425

CAUTION

*

: Indicates parts which should be partially tightened, and then fully tightened after placing the vehicle

on the ground and loading the full weight of the engine on the vehicle body.

AC001639AG

30 ± 3 N·m

23 ± 2 ft-lb

7

12 ± 2 N·m

102 ± 22 in-lb

88 ± 10 N·m

65 ± 7 ft-lb

2

1

8

6

5

4

3

<3.0L ENGINE>

30 ± 3 N·m

23 ± 2 ft-lb

73 ± 10 N·m

54 ± 7 ft-lb

REMOVAL STEPS

1.

TRANSAXLE CONTROL CABLE

CONNECTION

2.

TRANSAXLE OIL COOLER

HOSES CONNECTION

3.

TRANSMISSION RANGE

SWITCH CONNECTOR

4.

A/T CONTROL SOLENOID

VALVE ASSEMBLY

CONNECTOR

5.

INPUT SHAFT SPEED SENSOR

CONNECTOR

6.

OUTPUT SHAFT SPEED

SENSOR CONNECTOR

<<A>>

7.

STARTER MOTOR

8.

TRANSAXLE UPPER

CONNECTING BOLTS

REMOVAL STEPS (Continued)