Mitsubishi Eclipse. Manual - part 853

A/T KEY INTERLOCK AND SHIFT LOCK MECHANISMS

TSB Revision

AUTOMATIC TRANSAXLE

23A-421

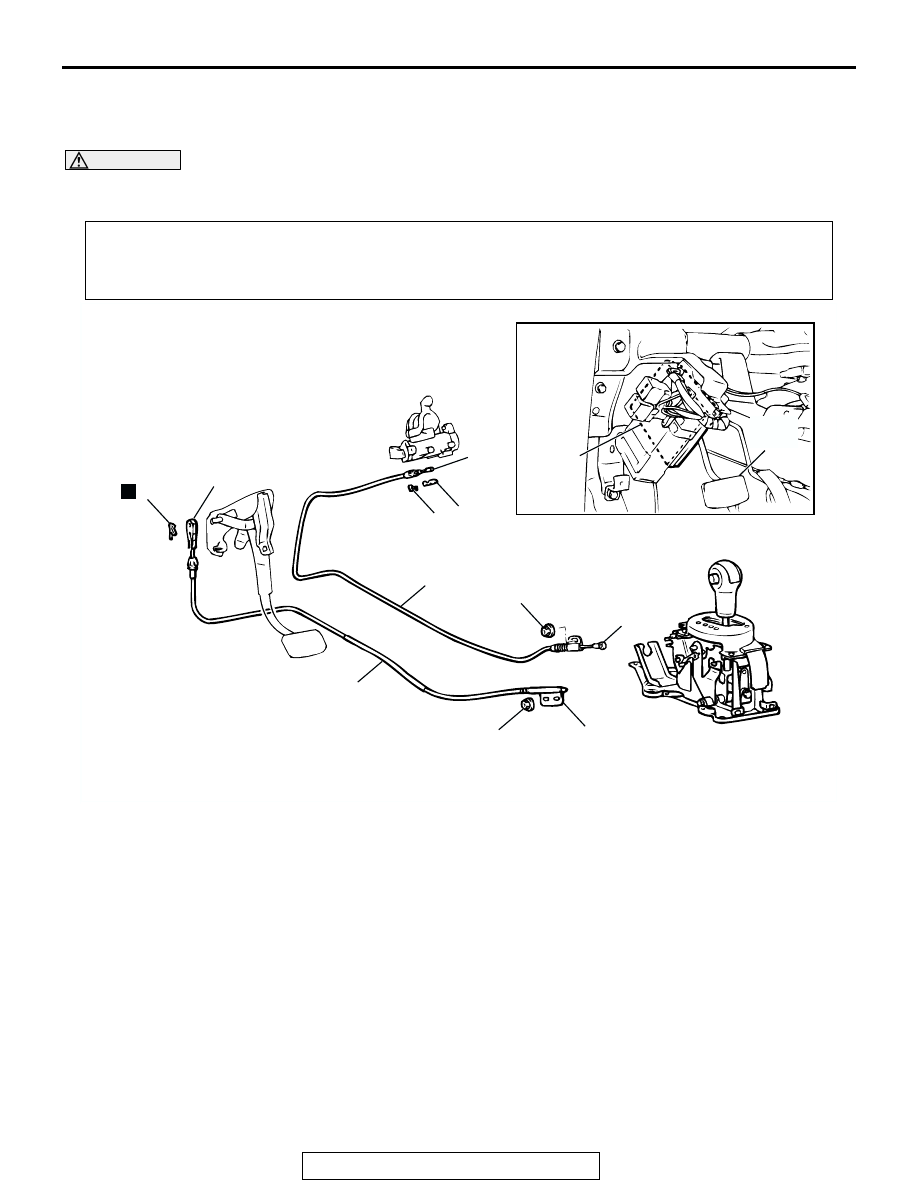

A/T KEY INTERLOCK AND SHIFT LOCK MECHANISMS

REMOVAL AND INSTALLATION

M1232001200411

CAUTION

When removing and installing the key interlock cable and shift lock cable, be careful not to hit the

SRS-ECU.

Pre-removal and Post-installation Operation

• Floor Console Removal and Installation (Refer to GROUP 52A

.)

• Key Interlock Mechanism Check (Refer to

.) <Post-installation>

• Shift Lock Mechanism Check (Refer to

.) <Post-installation>

AC001636AB

12 ± 2 N·m

102 ± 22 in-lb

7

N

6

9

BRAKE

PEDAL

1

10

12 ± 2 N·m

102 ± 22 in-lb

5

4

3

2

8

KEY INTERLOCK CABLE

REMOVAL STEPS

>>C<<

1.

KEY INTERLOCK CABLE

CONNECTION (SELECTOR

LEVER SIDE)

•

LOWER COLUMN COVER

(REFER TO GROUP 37A,

STEERING WHEEL AND SHAFT

2.

COVER

>>B<<

3.

KEY INTERLOCK CABLE

CONNECTION (STEERING

LOCK CYLINDER SIDE)

4.

SLIDER

5.

KEY INTERLOCK CABLE

SHIFT LOCK CABLE REMOVAL

STEPS

>>A<<

6.

SHIFT LOCK CABLE

CONNECTION (SELECTOR

LEVER SIDE)

7.

COTTER PIN

8.

SHIFT LOCK CABLE

CONNECTION (BRAKE PEDAL

SIDE)

9.

SHIFT LOCK CABLE

ETACS-ECU REMOVAL

10. ETACS-ECU