Mitsubishi Canter (FE, FG). Manual - part 29

116

7 Construction of bodies

7.2 Mounting frame

MITSUBISHI FUSO body/equipment mounting directives for FE, FG Issue date: 06. 07. 2012

!

Only print out complete sections from the current version

i

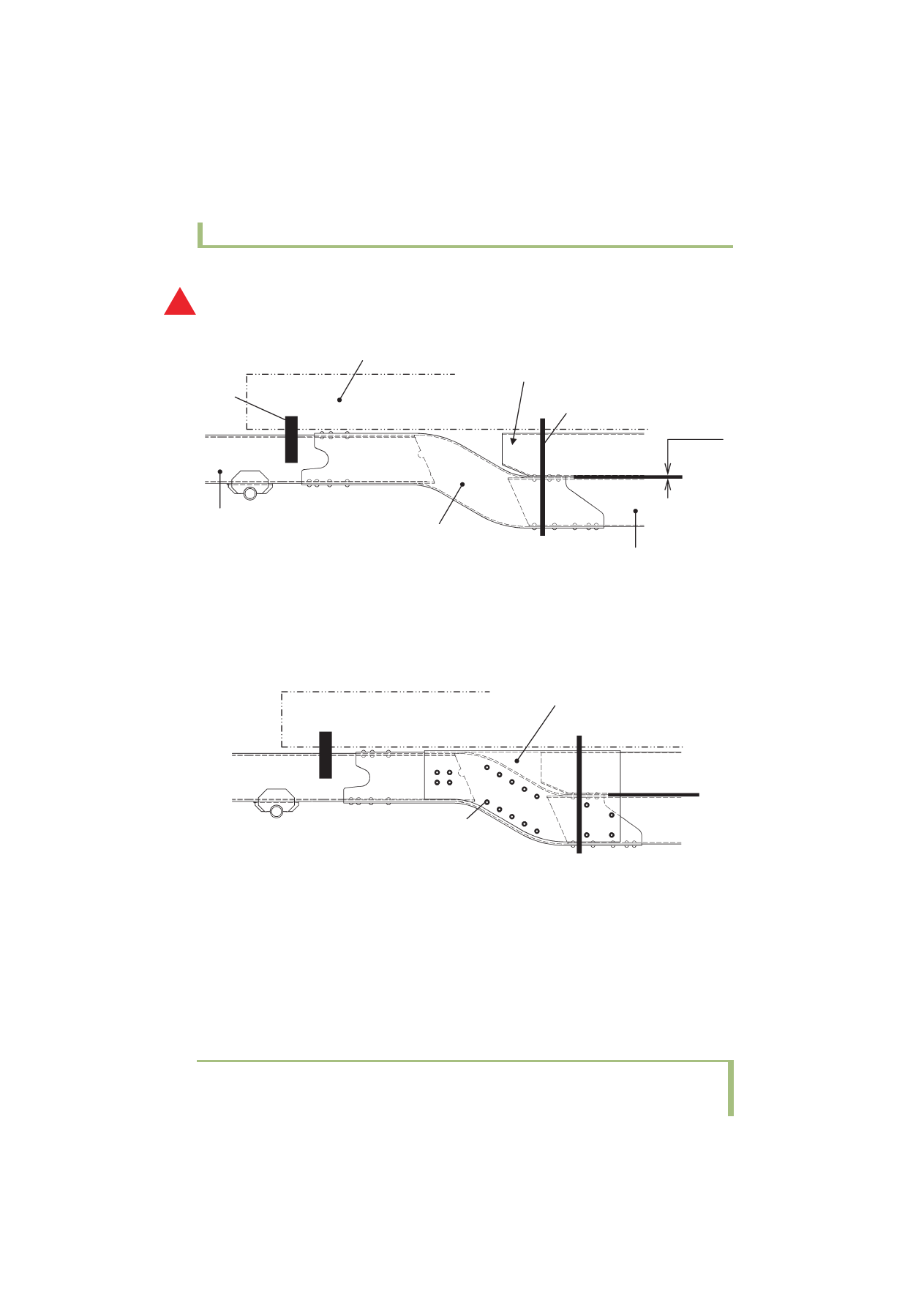

(d) When building a body to the frame of a 4 WD vehicle (FGB model), follow the instructions below.

• In the case of an ordinary body

Join the front end to the FR side rail (1). If this is not possible, join the body to the section where the

RR side rail and kick-down rail overlap (2).

• In the case of a body that applies concentrated load or excessive force to the frame, or if an excessive

twisting force may be applied to the frame on rough roads or muddy ground

Add an L-shaped reinforcing member as shown below.

Use M10 bolts (8T) and nuts (6T) with a tightening torque of 60 to 80 N•m {43 to 58 ft.lbs, 6 to 8

kgf•m} to secure the member together with the existing battery, fuel tank, spare tire hanger, etc.

A

Body

Position the sub-frame as far forward

as possible.

FR side rail

Kick-down rail

RR side rail

(Spacer)

t6

(1)

(2)

Fig. 5

L-shaped reinforcing member

Bolt

Fig. 6