Mitsubishi Grandis. Manual - part 974

DIFFERENTIAL

AUTOMATIC TRANSMISSION OVERHAUL

23B-52

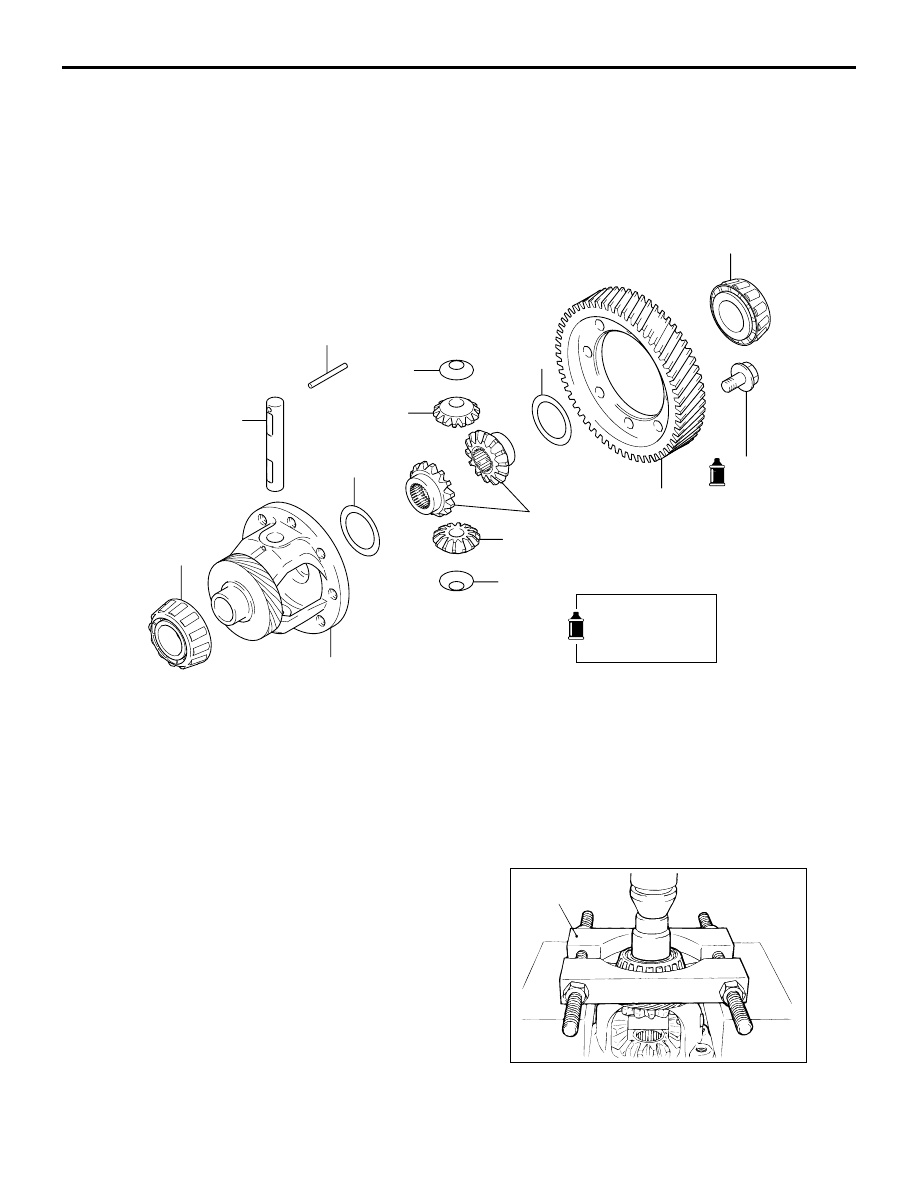

DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

M1233003100316

DISASSEMBLY SERVICE POINTS

<<A>> TAPER ROLLER BEARING

REMOVAL

Use the special tool Bearing remover (MD998801) to

remove the taper roller bearings.

AK101411

135 ± 5 N·m

1

2

8

6

5

3

4

7

5

6

8

9

2

AC

Apply automatic

transmission fluid

to all moving parts

before installation.

Disassembly steps

>>D<<

1.

Differential drive gear

<<A>>

>>C<<

2.

Taper roller bearing

>>B<<

3.

Lock pin

>>A<<

4.

Pinion shaft

>>A<<

5.

Pinion

>>A<<

6.

Washer

>>A<<

7.

Side gear

>>A<<

8.

Spacer

9.

Differential case

AK100576

MD998801

AC