Mitsubishi Grandis. Manual - part 972

REVERSE AND OVERDRIVE CLUTCH

AUTOMATIC TRANSMISSION OVERHAUL

23B-44

DISASSEMBLY SERVICE POINTS

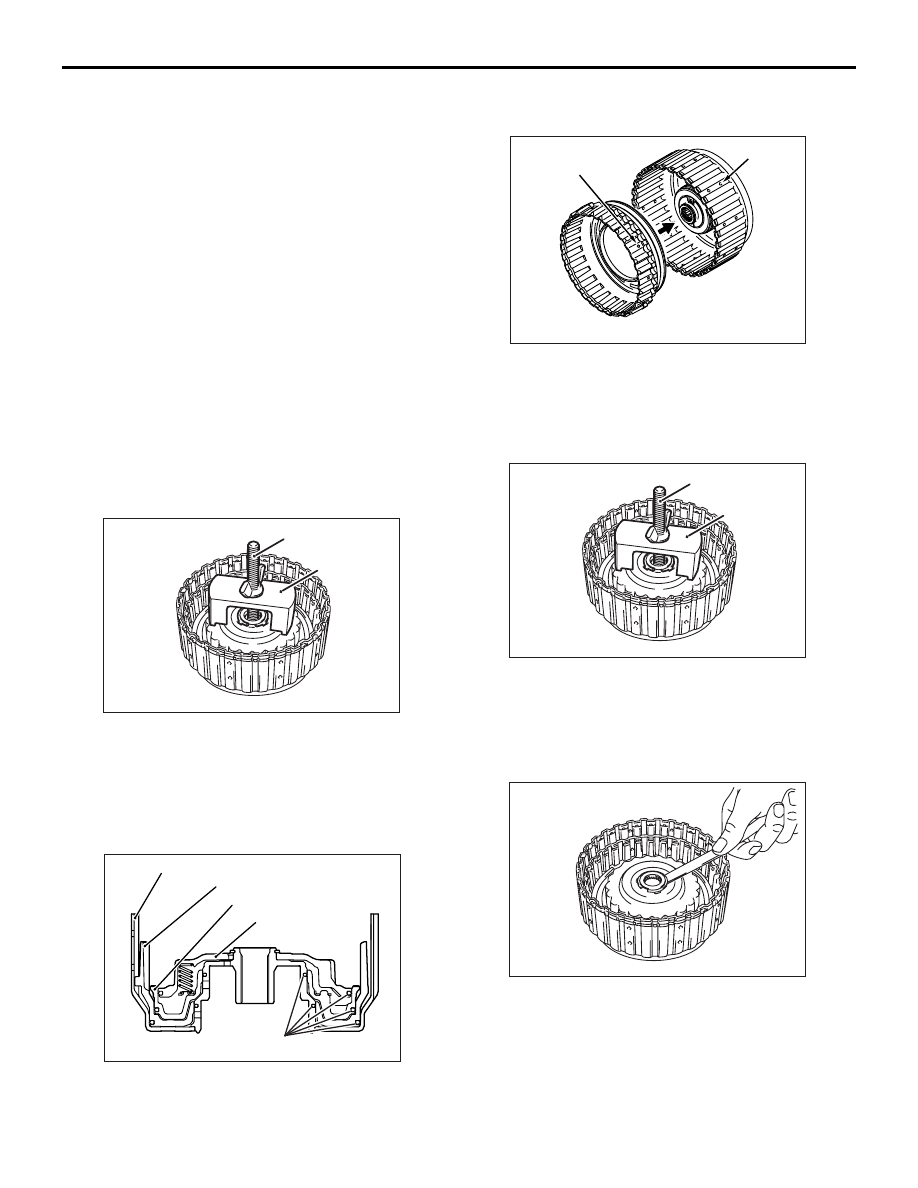

<<A>> SNAP RING REMOVAL

Use the special tools to remove the snap ring.

• Spring compressor retainer (MD998924)

• Spring compressor (MD999590)

REASSEMBLY SERVICE POINTS

>>A<< D-RING INSTALLATION

Apply ATF, blue petrolatum jelly or white Vaseline to

the D-rings and handle them carefully to avoid

damage during installation.

>>B<< REVERSE CLUTCH PISTON

INSTALLATION

Assemble the reverse clutch piston with the reverse

clutch retainer with their holes (A and B in the

drawing) aligned.

>>C<< SNAP RING INSTALLATION

1. Use the special tools to install the snap ring.

• Spring compressor retainer (MD998924)

• Spring compressor (MD999590)

2. Press down the return spring retainer tightly on its

entire circumference (with a force of 49N).

3. Check the clearance between the snap ring and

the return spring retainer. If the clearance is not

within the standard value range, make adjustment

by selecting a snap ring of an appropriate

thickness.

Standard value: 0

− 0.09 mm

Disassembly steps

>>G<<

1.

Snap ring

>>F<<

2.

Clutch reaction plate

>>F<<

3.

Clutch disc

>>F<<

4.

Clutch plate

>>E<<

5.

Snap ring

>>D<<

6.

Clutch reaction plate

>>D<<

7.

Clutch disc

>>D<<

8.

Clutch plate

<<A>>

>>C<<

9.

Snap ring

10. Spring retainer

>>A<<

11. D-ring

12. Clutch return spring

13. Overdrive clutch piston

>>A<<

14. D-ring

>>B<<

15. Reverse clutch piston

>>A<<

16. D-ring

>>A<<

17. D-ring

>>A<<

18. D-ring

19. Reverse clutch retainer

AK300525AC

MD999590

MD998924

AK301294

D-ring

Reverse clutch retainer

Reverse clutch piston

Overdrive clutch piston

Spring retainer

AB

AK301276AB

A

B

AK300525AC

MD999590

MD998924

AK300526