Mitsubishi Grandis. Manual - part 970

TRANSMISSION

AUTOMATIC TRANSMISSION OVERHAUL

23B-36

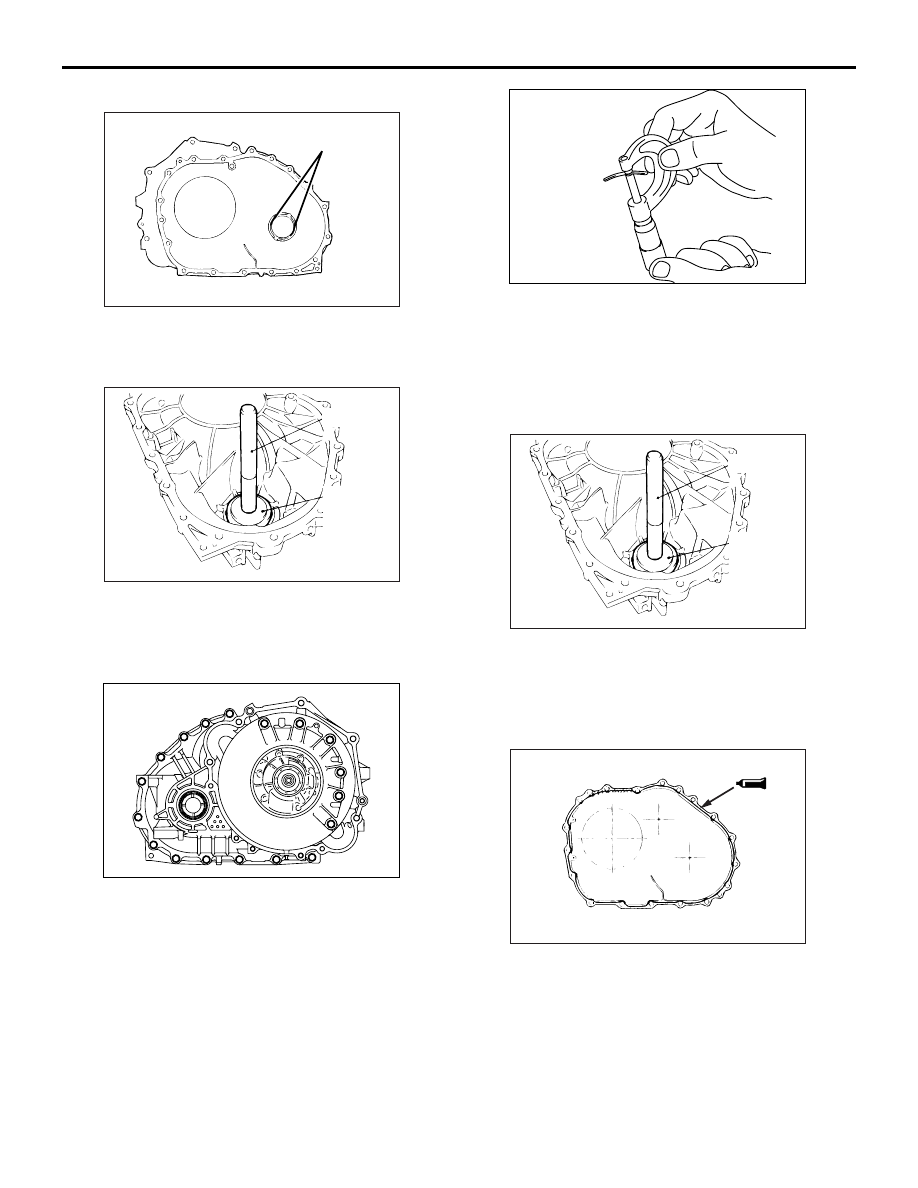

61.Install the differential.

62.Place two pieces of about 10mm long, 3mm

diameter solder on the converter housing at the

locations indicated in the drawing.

63.Use the special tools to drive the outer race into

position.

• Installer adapter (MB990935)

• Handle (MB990938)

64.Install the converter housing on the transmission

case without applying FIPG. Tighten the mounting

bolts to the specified torque of 48

± 6 N⋅m.

65.Remove the bolts and converter housing, and

take out the solder pieces.

66.Use a micrometer to measure the thickness of the

crashed solder.

67.Select a spacer of the thickness equivalent to the

micrometer reading plus the standard preload

value.

Standard preload value: 0.045

− 0.105mm

68.Install the spacer selected in step 67. into the

converter housing and drive the outer race into

position using the special tools.

• Installer adapter (MB990935)

• Handle (MB990938)

69.Apply an approx. 1.6 mm diameter bead of

from-in-place gasket (FIPG) to the converter

housing along its circumference as shown in the

drawing.

Specified sealant:

Mitsubishi genuine sealant Part No. MD974421

or equivalent

AK201992

Solder

AB

AK100362 AE

MB990938

MB990935

AK301084

AK301249

AK100362 AE

MB990938

MB990935

AK201994