Mitsubishi L200. Manual - part 434

ON-VEHICLE SERVICE

ANTI-SKID BRAKING SYSTEM (ABS)

35B-57

ON-VEHICLE SERVICE

WHEEL SPEED SENSOR OUTPUT

CURRENT MEASUREMENT

M1352032800065

The relevant wheel, on which the wheel speed sen-

sor is fitted, should be free to run.

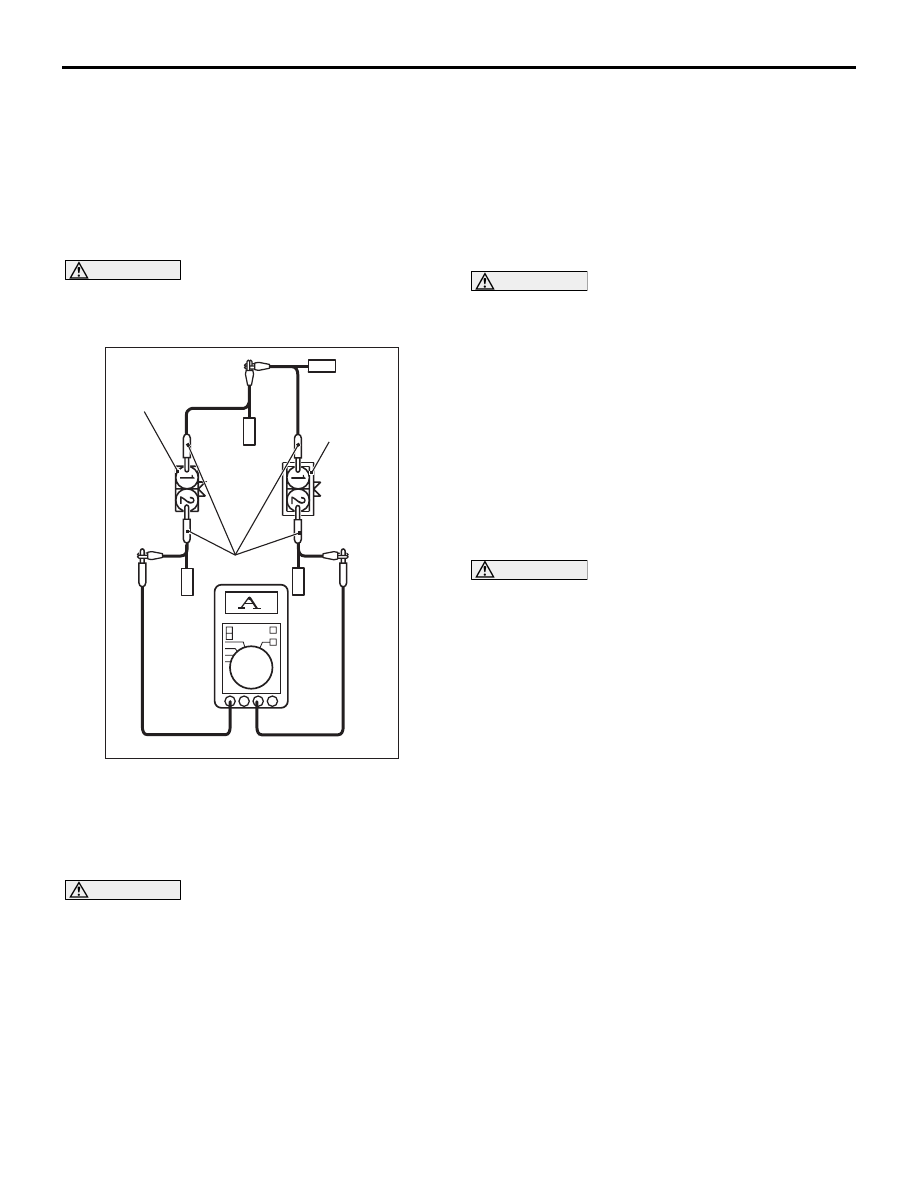

1. Remove the wheel speed sensor connector to be

checked.

CAUTION

For precise measurement, do not connect to the

wheel speed sensor-side connector and the wir-

ing harness side connector terminal No.1.

ACB00833

MB991709

AB

Wheel speed

sensor

connector

Harness

connector

2. Use the special tool test harness (MB991709) to

connect a multimeter between the wheel speed

sensor-side connector and the wiring harness

connector terminal No.2.

3. Turn the ignition switch to the "ON" position.

CAUTION

Do not rotate the wheel too quickly. Output cur-

rent changes significantly as the wheel speed

detection magnetic encoder comes near or goes

away from the wheel speed sensor.

4. Rotate the wheel, on which the wheel speed

sensor is fitted, quite slowly to measure the output

current with the multimeter.

Standard value: 5 to 9 mA or 11 to 17 mA

5. If the measurement is not within the standard

value, or the output current does not change in

proportion to the wheel rotation, replace the wheel

speed sensor (Refer to

HYDRAULIC UNIT CHECK

M1352001701106

CAUTION

• The roller of the braking force tester and the

tyre should be dry during testing.

• When testing the front brakes, apply the park-

ing brake. When testing the rear brakes, stop

the front wheels with chocks.

1. Jack up the vehicle. Then support the vehicle with

rigid racks at the specified jack-up points or place

the front or rear wheels on the rollers of the

braking force tester.

2. Release the parking brake, and feel the drag force

(drag torque) on each road wheel. When using

the braking force tester, take a reading of the

brake drag force.

CAUTION

To prevent damage to M.U.T.-III, always turn the

ignition switch to the "LOOK" (OFF) position

before connecting or disconnecting the M.U.T.-III.

3. Turn the ignition switch to the "LOCK" (OFF)

position and set the M.U.T.-III as shown in the

illustration.

4. After checking that the selector lever is in neutral,

start the engine.

5. Use the M.U.T.-III to force-drive the actuator.

NOTE: The ABS system will switch to the M.U.T.-

III mode and the ABS warning lamp will illuminate.

NOTE: When the ABS has been interrupted by

the fail-safe function, the M.U.T.-III actuator test-

ing cannot be used.