Mitsubishi L200. Manual - part 338

AKX00151

17

18

19

20

25

26

27

22

23

24

28

29

30

21

35

36

37

32

33

34

38

31

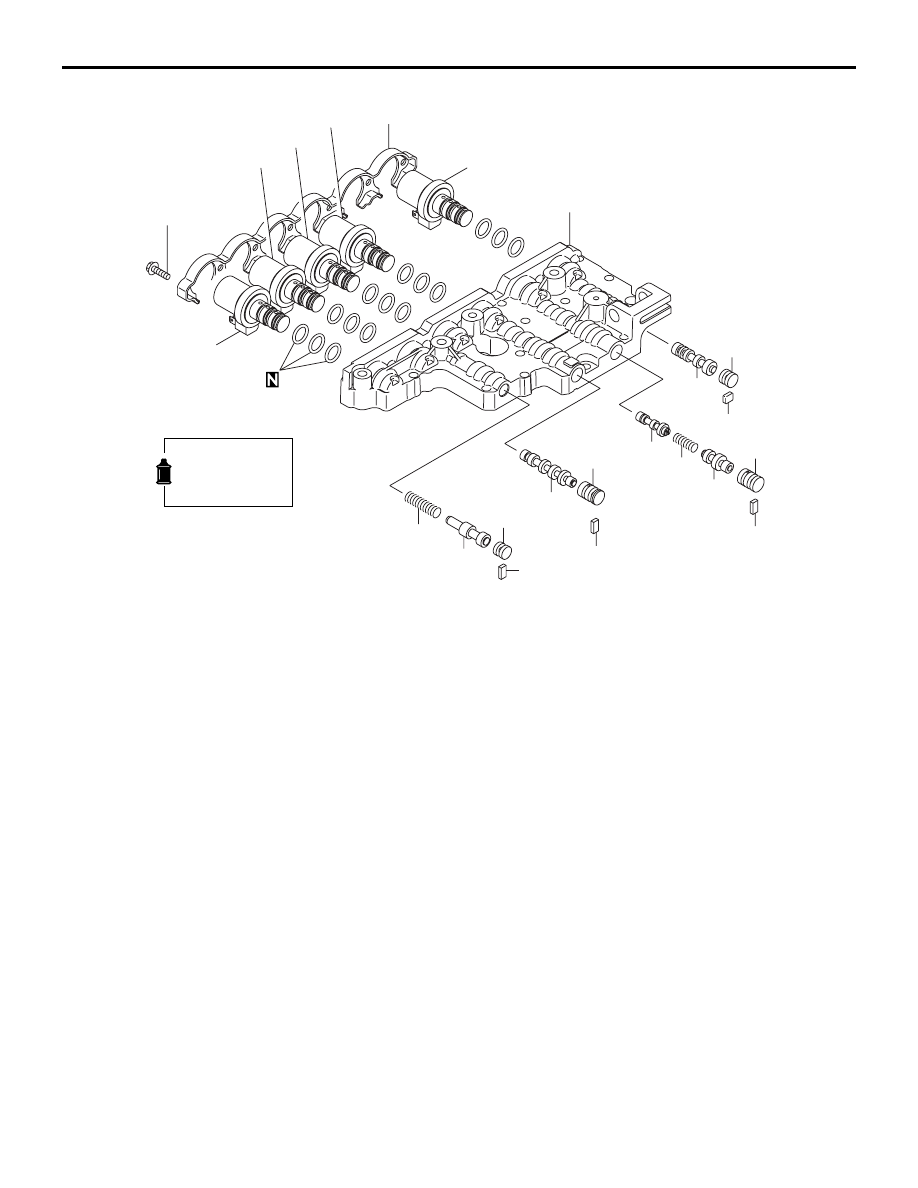

Apply automatic

transmission fluid

to all moving parts

before installation.

6.0 ± 1.0 N·m

AC

Disassembly steps

17. Solenoid support

<<

A

>>

>>

A

<<

18. Low reverse brake solenoid valve

<<

A

>>

>>

A

<<

19. Second brake solenoid valve

<<

A

>>

>>

A

<<

20. Underdrive clutch solenoid valve

<<

A

>>

>>

A

<<

21. Overdrive clutch solenoid valve

<<

A

>>

>>

A

<<

22. Torque converter clutch control

solenoid valve

23. Stopper plate

24. Stopper plug

25. Switching valve

26. Stopper plate

27. Fail-safe valve a sleeve

28. Fail-safe valve A2

29. Fail-safe valve A spring

30. Fail-safe valve A1

31. Stopper plate

32. Fail-safe valve B sleeve

33. Fail-safe valve B

34. Stopper plate

35. Stopper plug

36. Torque converter pressure control

valve

37. Torque converter pressure control

valve spring

38. Upper valve body

VALVE BODY

AUTOMATIC TRANSMISSION OVERHAUL <V4A5>

23C-61

Disassembly steps (Continued)