Mitsubishi L200. Manual - part 337

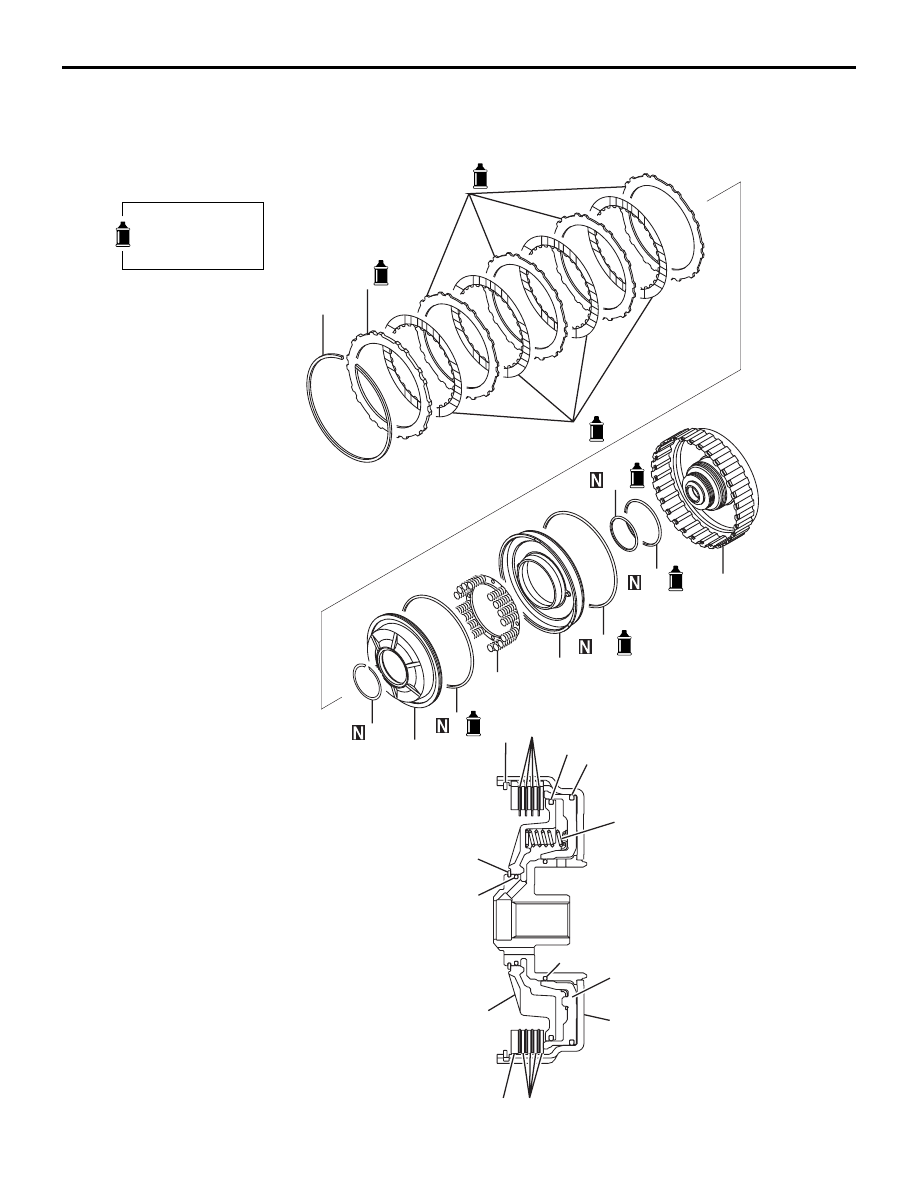

UNDERDRIVE CLUTCH

AUTOMATIC TRANSMISSION OVERHAUL <V4A5>

23C-57

UNDERDRIVE CLUTCH

DISASSEMBLY AND REASSEMBLY

M1233027300284

AK700896

4

5

6

1

2

3

7

8

9

11

12

13

10

4

5

6

1

2

3

7

8

9

11

12

13

10

AB

Apply automatic

transmission fluid

to all moving parts

before installation.