Mitsubishi L200. Manual - part 336

SECOND BRAKE

AUTOMATIC TRANSMISSION OVERHAUL <V4A5>

23C-53

1. Install the snap ring in the reverse clutch retainer

groove.

2. Set special tools as shown in the illustration, and

compress the clutch element.

• Spring compressor (MB991789)

• Spring compressor retainer (MD998924)

3. Check that the clearance between the snap ring

and the clutch reaction plate is within the standard

valus.If not within the standard value, select a

snap ring to adjust.

Standard value: 1.5

− 1.7 mm

(For reverse clutch end play)

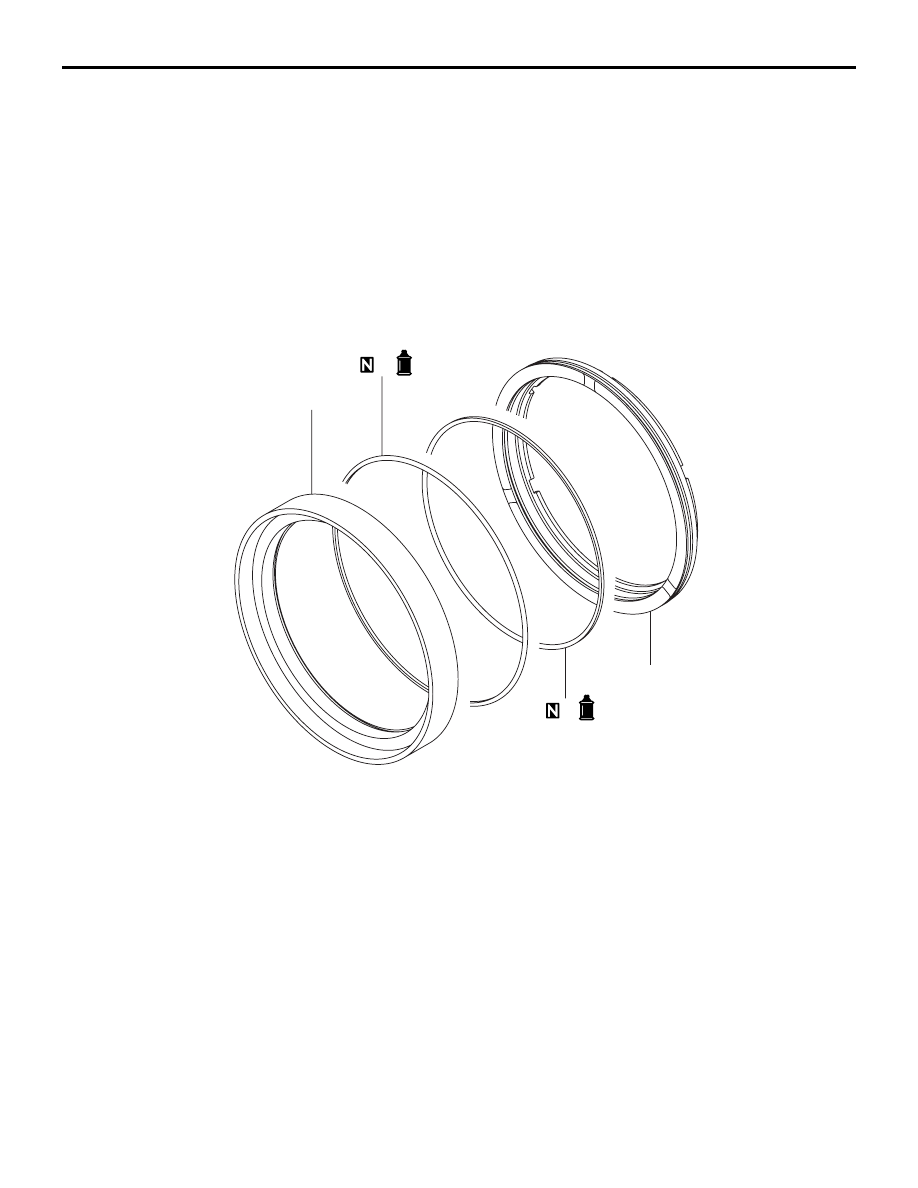

SECOND BRAKE

DISASSEMBLY AND REASSEMBLY

M1233021800269

AKX00134

1

2

3

4

AB

Disassembly steps

1.

Second brake retainer

2.

Second brake piston

>>

A

<<

3.

D-ring

>>

A

<<

4.

D-ring

REASSEMBLY SERVICE POINT

>>A<< D-RING INSTALLATION

1. Apply ATF to the D-ring.

2. Install the D-ring in the grooves on the outer and

inner periphery of the piston. Make sure that the

D-ring is not twisted or damaged when installing.