Mitsubishi L200. Manual - part 335

AK403457AB

Transmission

side

Identification

symbol A

TRANSMISSION

AUTOMATIC TRANSMISSION OVERHAUL <V4A5>

23C-49

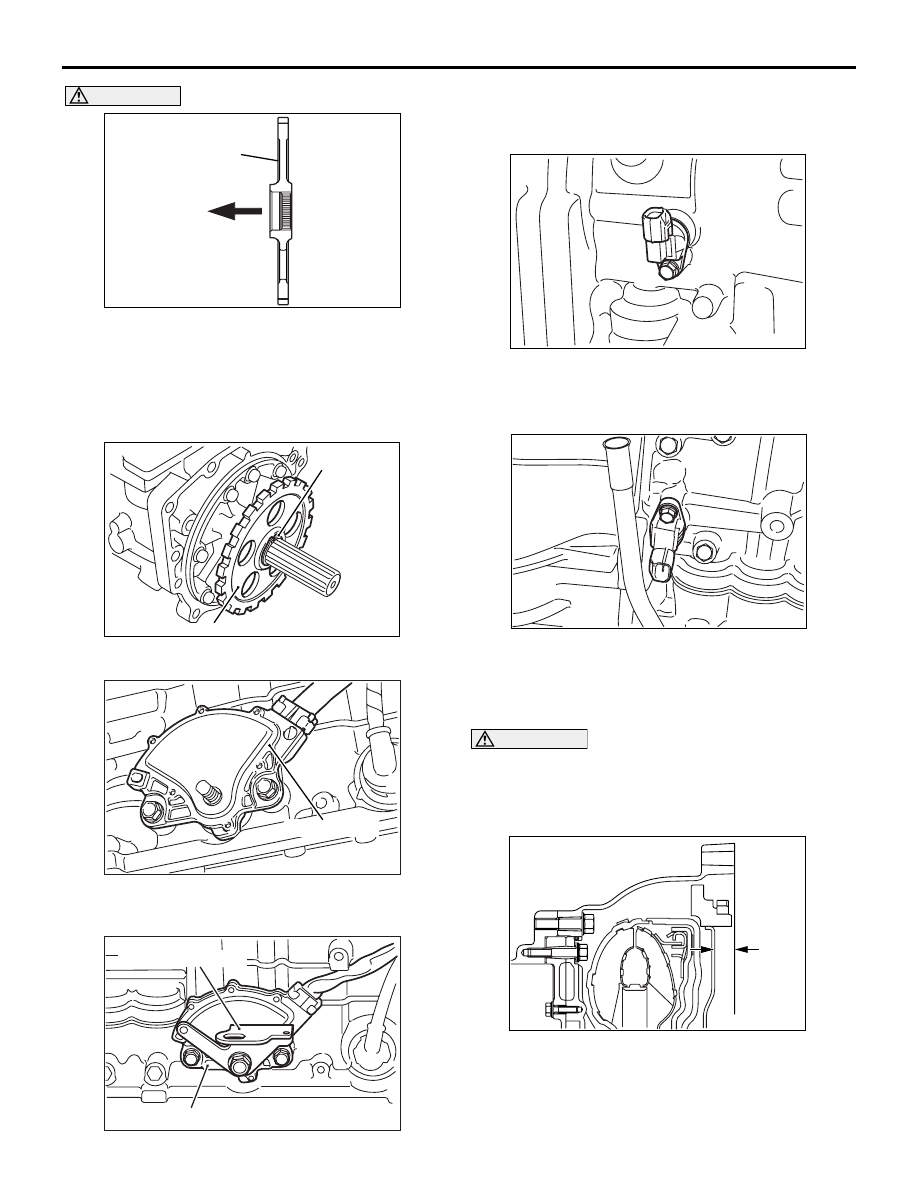

CAUTION

• Install the parking gear so that the side with-

out the spline cut faces the transmission side.

• Heat the parking gear to 160 − 180 °C and

shrink fit up to the stepped section of the out-

put shaft. Do not heat for longer than neces-

sary at this time.

AK403344AB

Snap ring

Parking gear

65.Install the parking gear and snap ring.

AK601368AC

Inhibitor switch

66.Install the inhibitor switch, and fix the fastening

bolts temporarily.

AK403343

Inhibitor switch

Manual control lever

AB

67.Install the manual control lever.

68.Tighten the manual control lever mounting bolts to

the specified torque 21.5

± 3.5 N⋅m.

AK403342

69.Install the output shaft speed sensor.

70.Tighten the output shaft speed sensor mounting

bolts to the specified torque 11

± 1 N⋅m.

AK403341

71.Install the input shaft speed sensor.

72.Tighten the input shaft speed sensor mounting

bolts to the specified torque 11

± 1 N⋅m.

CAUTION

Apply ATF to the oil pump drive hub before

installing the torque converter. Be careful not to

damage the oil seal lip when installing the torque

converter.

AK403458AB

A

73.Install the torque converter, and secure it so that

the dimension (A) indicated in the illustration

meets the reference value.

Reference value: 20.9 mm