Mitsubishi L200. Manual - part 235

EMISSION CONTROL

ENGINE AND EMISSION CONTROL

17-44

If the PM accumulates more than the standard, the

engine-ECU carries out the control that automatically

regenerates the DPF under certain conditions to

remove the PM. At the DPF regeneration, the DPF

temperature gets high and high temperature exhaust

gases are given off.

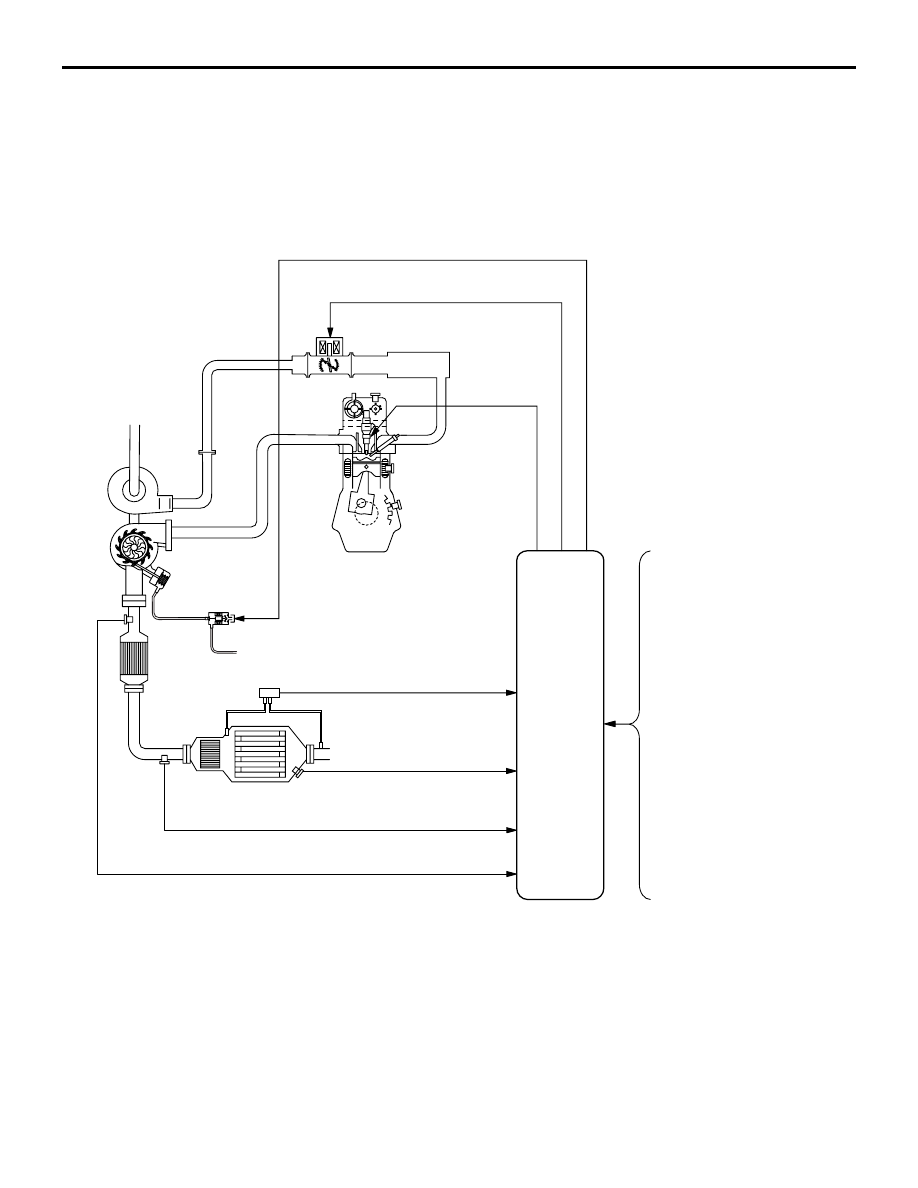

SYSTEM DIAGRAM

AKB00299

Engine-ECU

Rail pressure sensor

Accelerator pedal position

sensor

Vehicle speed sensor

AB

Air flow sensor

No. 1 intake air temperature

sensor

EGR gas temperature sensor

Crank angle sensor

Engine coolant temperature

sensor

Manifold absolute pressure

sensor

Injector

No. 1 exhaust gas temperature sensor

No. 2 exhaust gas temperature sensor

(catalyst temperature)

No. 3 exhaust gas temperature

sensor (DPF temperature)

Exhaust differential

pressure sensor

Catalytic

converter

Catalytic

converter

DPF

Variable geometry

control solenoid valve

Throttle valve control

servo (DC motor)