Mitsubishi L200. Manual - part 233

EMISSION CONTROL

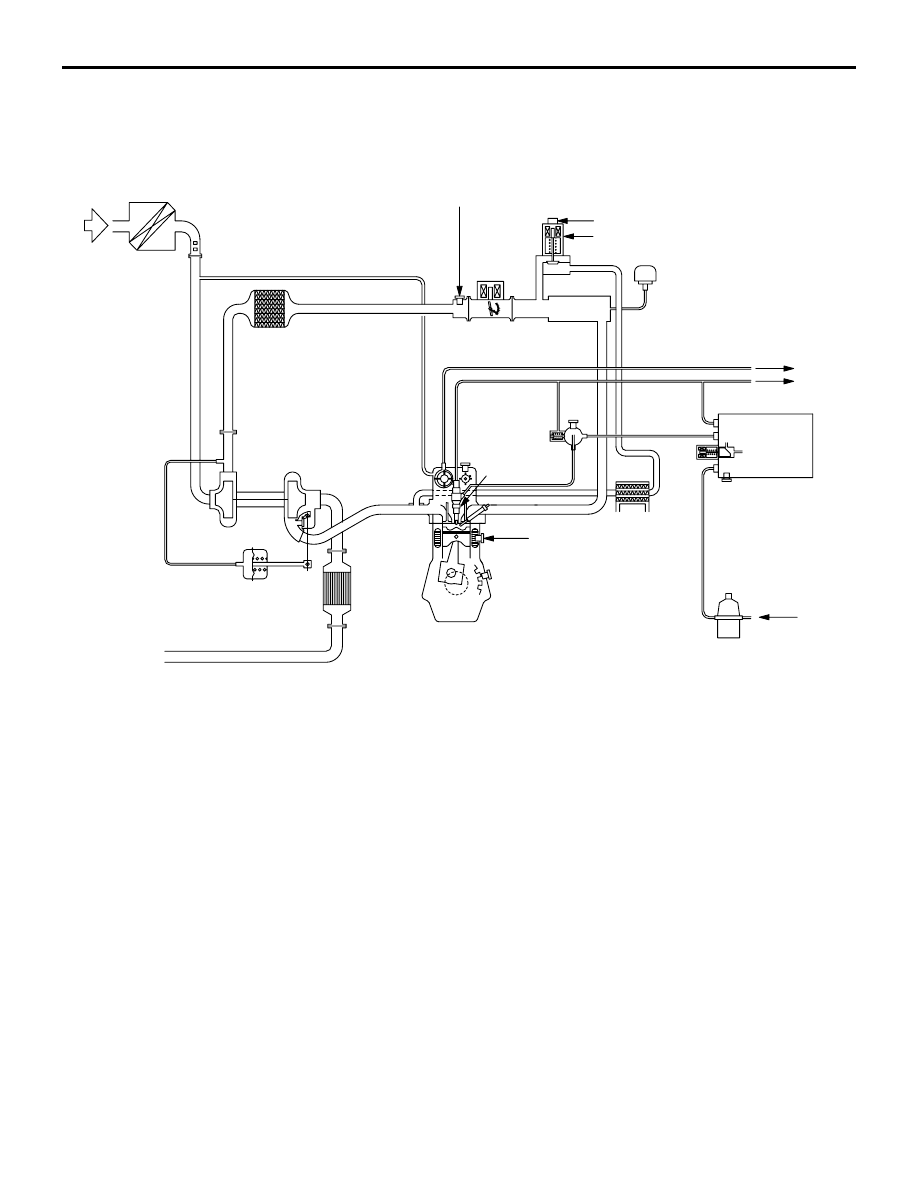

ENGINE AND EMISSION CONTROL

17-36

<Except Euro5>

AK500419

Waste gate

actuator

Catalytic

converter

EGR valve (DC motor)

Engine coolant

temperature sensor

Air

Injector

From fuel

tank

To fuel tank

To brake system

AB

Intake air temperature sensor No. 2

EGR valve position sensor