Mitsubishi L200. Manual - part 35

ALTERNATOR

ENGINE OVERHAUL

11B-14

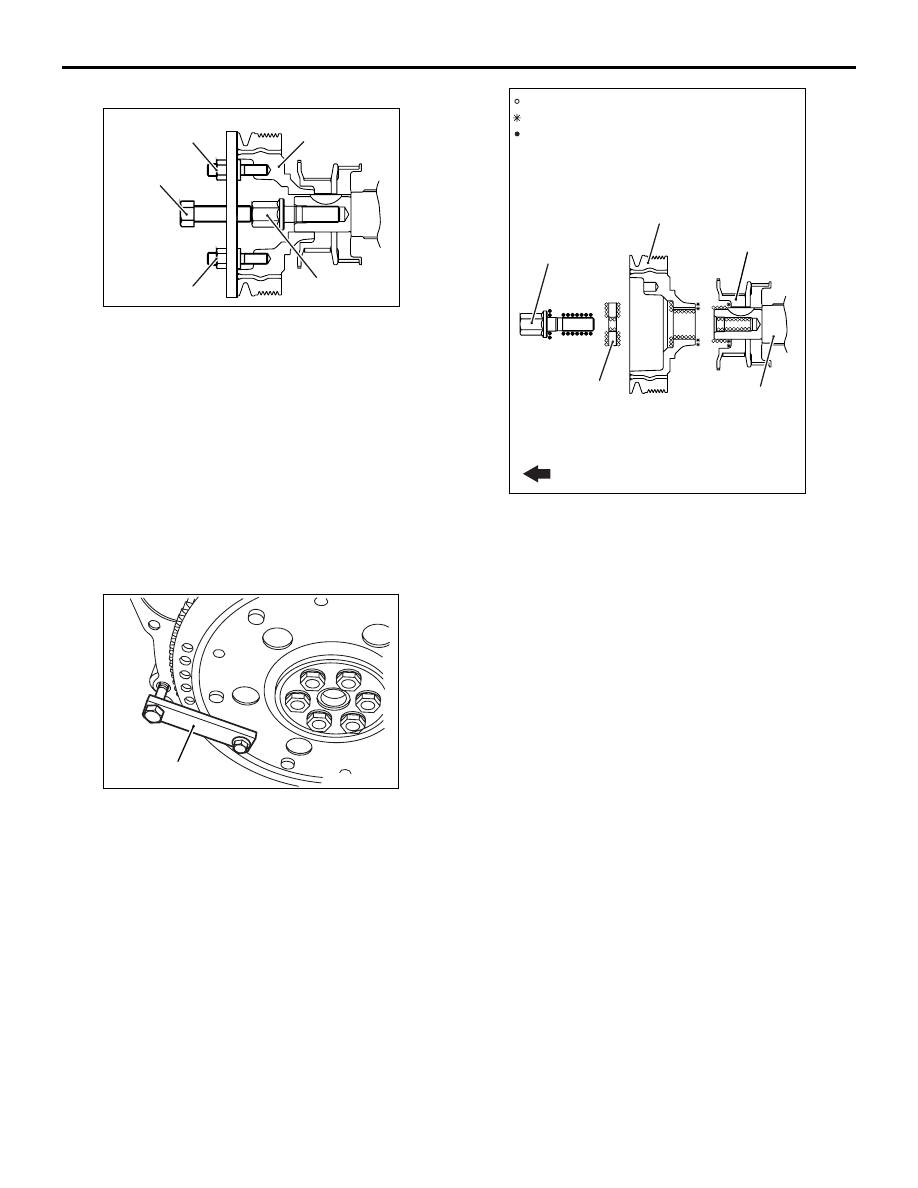

<<B>> CRANKSHAFT PULLEY REMOVAL

AK502851

Crankshaft

pulley

MB992099

AB

Crankshaft bolt

MB992100

MB992100

1. Screw securely the crankshaft bolt into the

crankshaft.

2. Use the special tool, remove the crankshaft

pulley.

• Crank pulley puller (MB992099)

• Crank pulley holder (MB992100)

3. Remove the crankshaft bolt.

INSTALLATION SERVICE POINTS

>>A<< CRANKSHAFT BOLT / CRANKSHAFT

PULLEY WASHER / CRANKSHAFT PULLEY

INSTALLATION

AK402854AB

MD998781

1. Use the special tool Flywheel stopper

(MD998781), hold the flywheel.

AK603656

Crankshaft

Crankshaft pulley

Crankshaft bolt

AB

Crankshaft

pulley washer

Crankshaft sprocket

: Wipe clean with a rag.

: Wipe clean with a rag and degrease.

: Wipe clean with a rag, degrease and

apply a small amount of engine oil.

Engine front

2. Wipe the dirt on the crankshaft pulley washer

using a rag.

3. Using a rag, wipe the dirt on the crankshaft pulley,

the crankshaft sprocket, the thread hole of the

crankshaft and then remove the grease.

NOTE: Degreasing is necessary to prevent

decrease in the friction between contacting sur-

faces.

4. Install the front flange and crankshaft pulley.

5. Apply an appropriate and minimum amount of

engine oil to the threads of crankshaft bolt and

lower part of the flange.

6. Install the crankshaft pulley washer to the

crankshaft bolt.

7. Tighten the crankshaft bolt to the specified torque

of 265 N

⋅m.

8. Loosen the bolt completely.

9. Tighten the crankshaft bolt again to the specified

torque of 275 N

⋅m.