Isuzu Trooper (1998-2002 year). Manual - part 563

6A – 60 ENGINE MECHANICAL

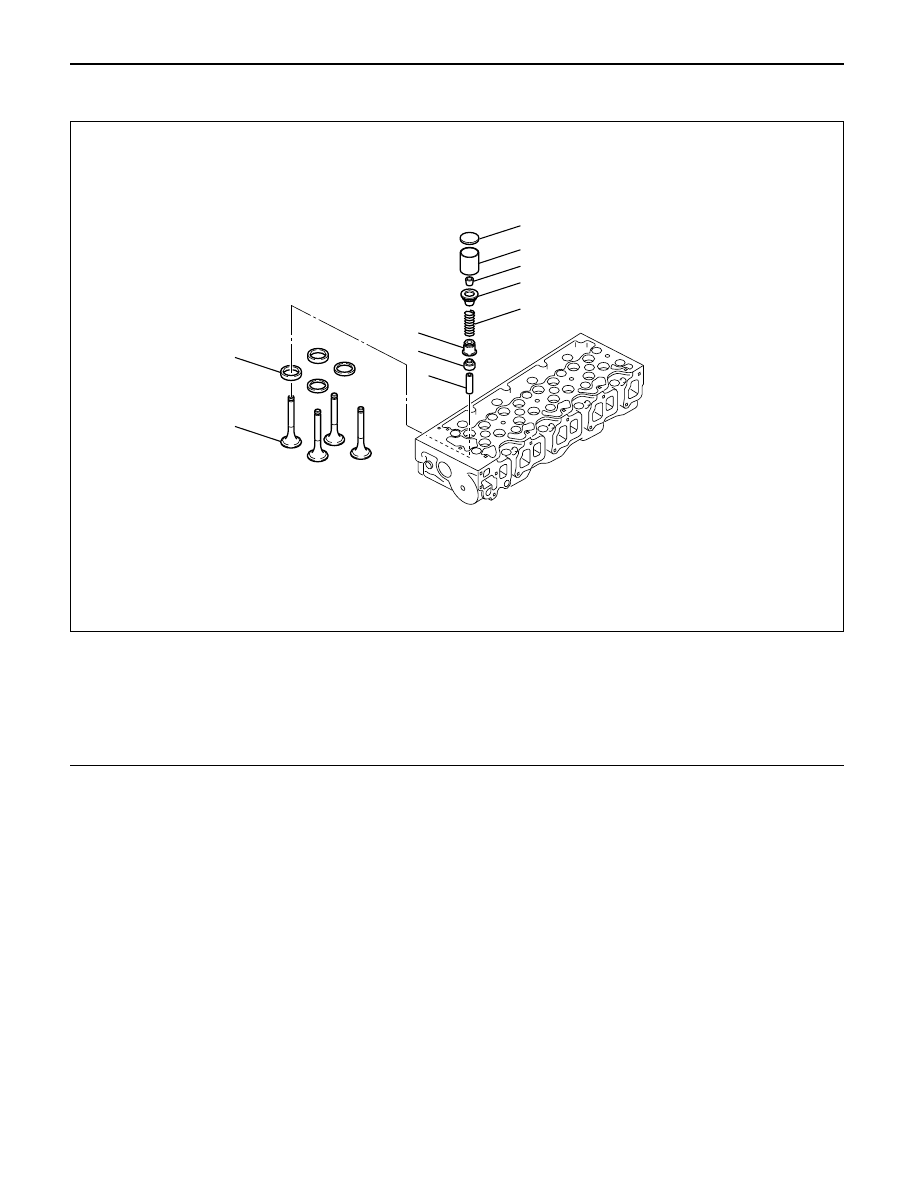

VALVE STEM SEAL, VALVE SPRING AND ADJUSTER

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove the air duct from between air cleaner and

turbocharger.

4. Remove intercooler assembly.

Refer to “Intercooler” in this manual.

5. Remove oil level gauge guide assembly.

6. Disconnect PCV hose.

7. Disconnect EGR vacuum hose.

8. Disconnect harness connectors around the cylinder

head such as the injector, CMP sensor, MAP

sensor, EGR sensor, EVRV, IAT sensor, A/C

compressor, TP stepping motor, TP sensor and fuel

temperature sensor etc.

9. Remove A/C compressor assembly.

10. Remove A/C compressor bracket.

11. Remove generator assembly and take out drive

belt.

12. Remove heat protector, remove exhaust valve

assembly.

13. Remove water cooling hose and lubrication pipe for

turbocharger.

14. Remove turbocharger assembly.

15. Remove hose between thermostat and radiator.

16. Remove noise insulator cover of cylinder head.

NOTE: Do not damage injector harness.

17. Remove high pressure oil pipe.

18. Remove timing belt cover.

19. Remove CMP sensor bracket.

20. Remove timing belt tensioner then remove timing

belt.

21. Remove camshaft pulley.

22. Remove front plate.

23. Remove engine coolant pipe between cylinder

head and water pump.

1

2

3

4

5

6

9

10

7

8

011RW031

Legend

(1)

Adjuster

(2)

Tappet

(3)

Split Collar

(4)

Spring Seat Upper

(5)

Valve Spring

(6)

Spring Seat Lower

(7)

Valve Stem Seal

(8)

Valve Guide

(9)

Valve Seat

(10)

Valve