Isuzu Trooper (1998-2002 year). Manual - part 562

6A – 56 ENGINE MECHANICAL

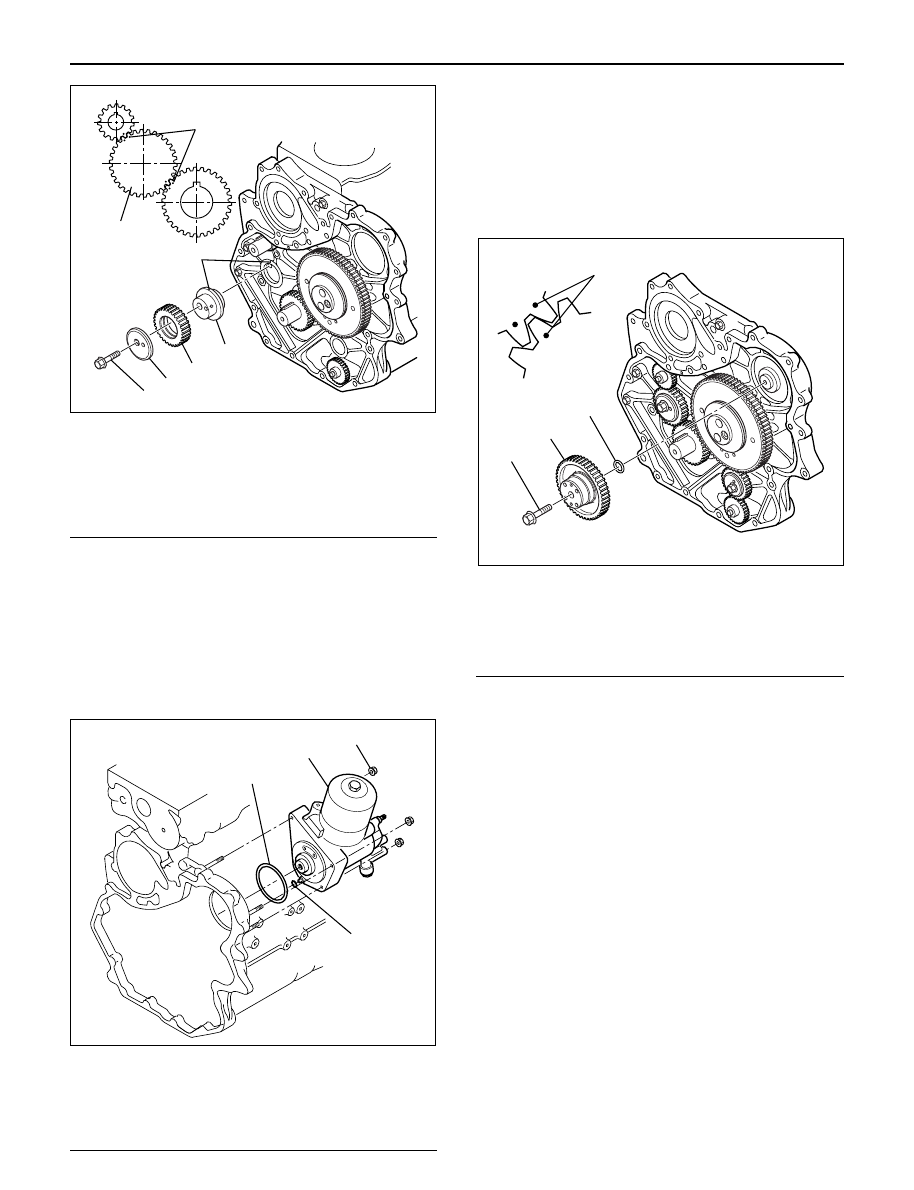

Legend

(1) Bolt

(2) Retainer

(3) Idle Gear B

(4) Idle Gear B Shaft

(5) Align Mark

6. High pressure oil pump

1) Install O-ring on the high pressure oil pump.

2) Install the high pressure oil pump to the timing

gear case, tighten the nut to the specified

torque. Apply Loctite No. 262 to the stud bolts.

Torque: 20 N·m (2.0 kg·m/14 lb ft)

NOTE: Be sure to set O-ring completely.

Legend

(1) O-ring (large)

(2) High pressure oil pump

(3) Nut

(4) O-ring (small)

7. High pressure oil pump

1) Install O-ring on the oil pump shaft with grease

and install the gear with the idle gear A timing

mark set at the oil pump gear timing mark.

2) Tighten center bolt to the specified torque.

Torque: 75 N·m (7.6 kg·m / 55 lb ft)

NOTE: Be sure to align timing marks with each other.

Legend

(1) O-ring

(2) High Pressure Oil Pump Gear

(3) Center Bolt

(4) Timing Mark

8. Remove lock from idle gear.

1) Remove lock bolt from idle gear A and remove

lock pin from idle gear C.

9. Timing gear case assembly

1) Clean fixing surface of timing gear case.

2) Install the gasket on the idle gear rear side end.

3) Apply liquid gasket (TB1207C or equivalent) to

the timing gear case fitting surface.

NOTE: Be sure to apply liquid gasket evenly.

4) Install timing gear case and tighten bolts to the

specified torque.

Torque: 20 N·m (2.0 kg·m / 14 lb ft)

NOTE: Must install within 5 minutes after applying liquid

gasket.

3

5

5

4

3

2

1

014R200008

1

2

4

3

040RW007

4

GEAR:O/PUMP

IDLE GEAR A

1

2

3

040RW005