Isuzu Trooper (1998-2002 year). Manual - part 561

6A – 52 ENGINE MECHANICAL

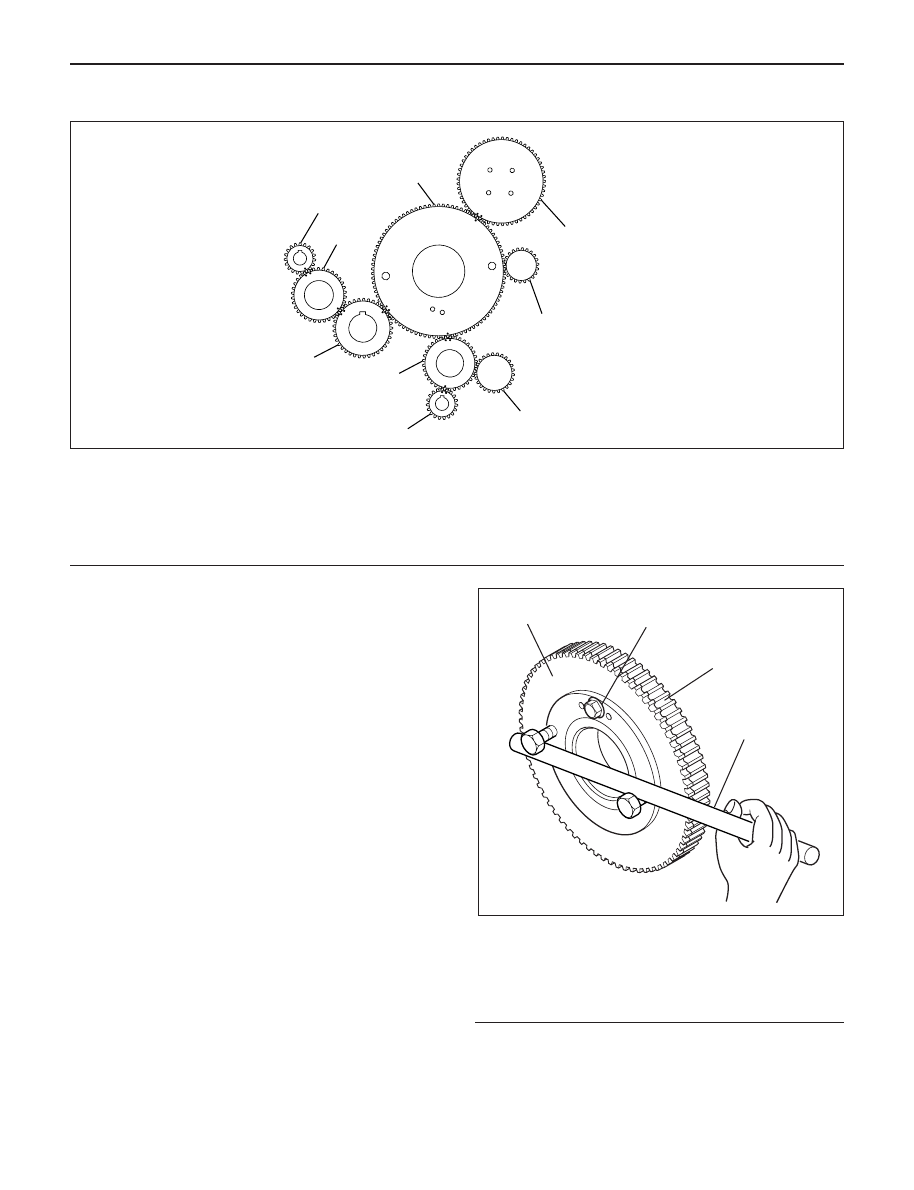

TIMING GEAR

REMOVAL

1. Loosen fixing bolt for generator and remove

generator assembly.

2. Remove fixing nuts, then remove cooling fan

assembly and fan pulley.

3. Remove crankshaft damper pulley.

4. Belt cover

1) Disconnect harness connector of CMP

(camshaft position) sensor.

2) Remove CMP sensor.

3) Remove belt cover.

5. Loosen belt tensioner to remove timing belt.

6. Remove camshaft pulley.

7. Remove high pressure oil pump pulley.

8. Remove front plate.

9. Remove vacuum pump.

10. Remove power steering pump.

11. Remove timing gear case cover assembly.

12. Idle gear A.

1) Set two bolts to sub gear of idle gear A and turn

it to align the tooth of idle gear A then lock them

by bolt as show in the illustration.

2) Remove idle gear A fixing bolts.

3) Remove idle gear A.

Legend

(1) Sub-Gear

(2) Main Gear

(3) Bar

(4) Locking Bolt

2

3

4

5

8

7

6

9

1

020RW028

Legend

(1)

Idle Gear A

(2)

High Pressure Oil Pump Gear

(3)

Vacuum Pump Gear

(4)

Power Steering Pump Gear

(5)

Balance Gear LH

(6)

Idle Gear C

(7)

Crankshaft Gear

(8)

Balance Gear RH

(9)

Idle Gear B

4

1

2

3

014RW177