Isuzu Trooper (1998-2002 year). Manual - part 560

6A – 48 ENGINE MECHANICAL

DISASSEMBLY

1. Injector clamp

2. Injector assembly

3. Oil rail assembly

4. Camshaft bracket

5. Camshaft

6. Oil seal

7. Plug

NOTE: Before starting disassembly above, drain oil

from oil rail to prevent oil from entering the cylinder.

REASSEMBLY

1. Camshaft

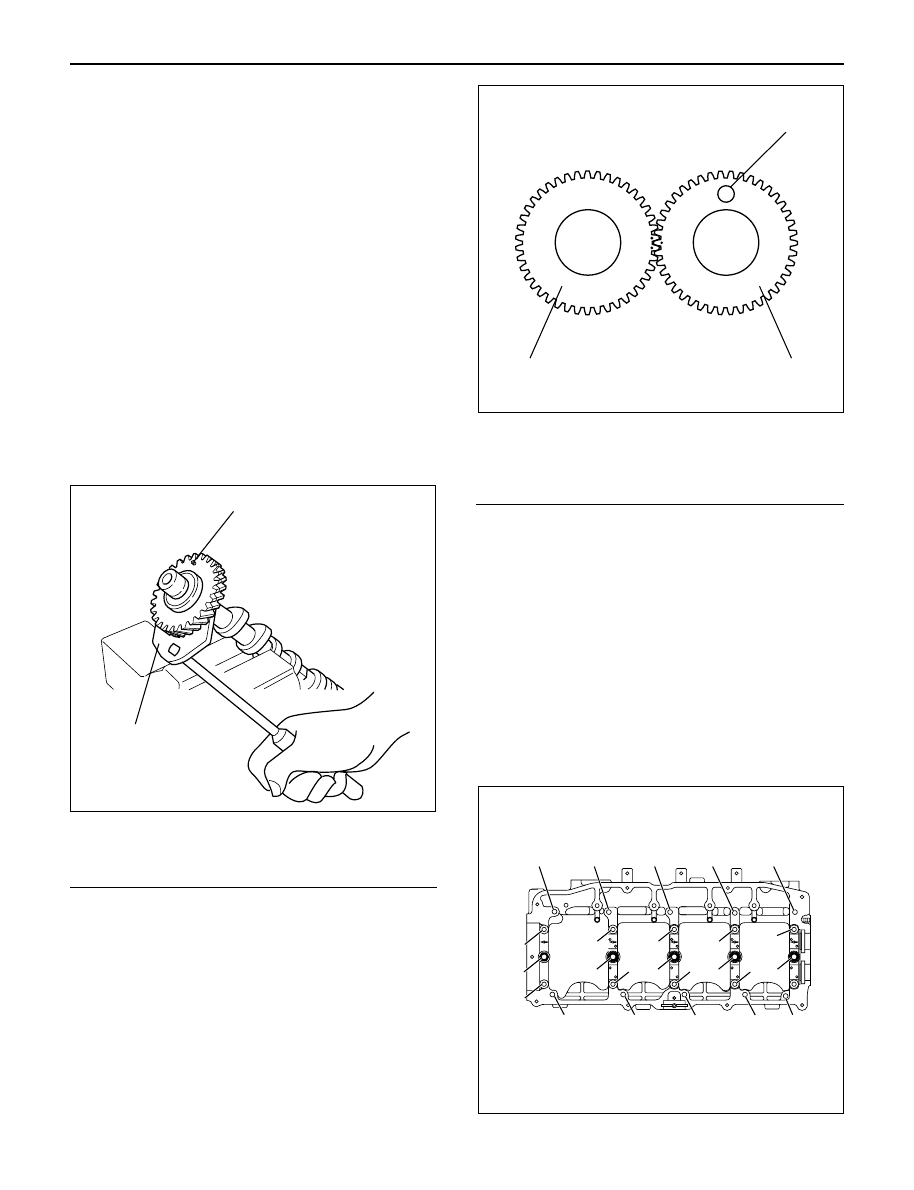

1) Before reassembling the camshaft to the

camshaft carrier, align the holes between the

main gear and the sub gear on the intake side of

the camshaft gear with a special tool.

2) Set lock pin to gear holes from sub gear side.

Camshaft Gear Tool: 5-8840-2591-0

Legend

(1) Locking pin

(2) Special tool

3) Apply engine oil to the camshaft gear tooth.

4) Apply engine oil to the journal on the camshaft

carrier.

5) Align the timing mark on the intake and exhaust

camshaft gear and put on the camshaft carrier.

Legend

(1) Locking pin

(2) Intake side camshaft gear

(3) Exhaust side camshaft gear

6) Apply liquid gasket (TB1207B or equivalent) to

No. 1 camshaft bracket matching surface.

7) Set No. 1 to No. 5 camshaft bracket on camshaft

carrier.

8) Temporarily tighten bracket bolts B and C.

Temporal Torque: 20 N·m (2.0 kg·m/14 lb ft)

9) Put gasket on the cylinder head.

10) Install camshaft carrier onto the cylinder head

and tighten bolts to specified torque.

Torque: A; 22 N·m (2.2 kg·m/16 lb ft)

B; 38 N·m (3.9 kg·m/28 lb ft)

C; 22 N·m (2.2 kg·m/16 lb ft)

D; 38 N·m (3.9 kg·m/28 lb ft)

•

Remove locking pin.

1

2

014RW183

3

2

1

014RW184

C

C

D

B

C

C

B

C

C

D

C

C

B

C

A

A

A

A

A

A

A

A

A

A

011RW035