Isuzu Trooper (1998-2002 year). Manual - part 564

6A – 64 ENGINE MECHANICAL

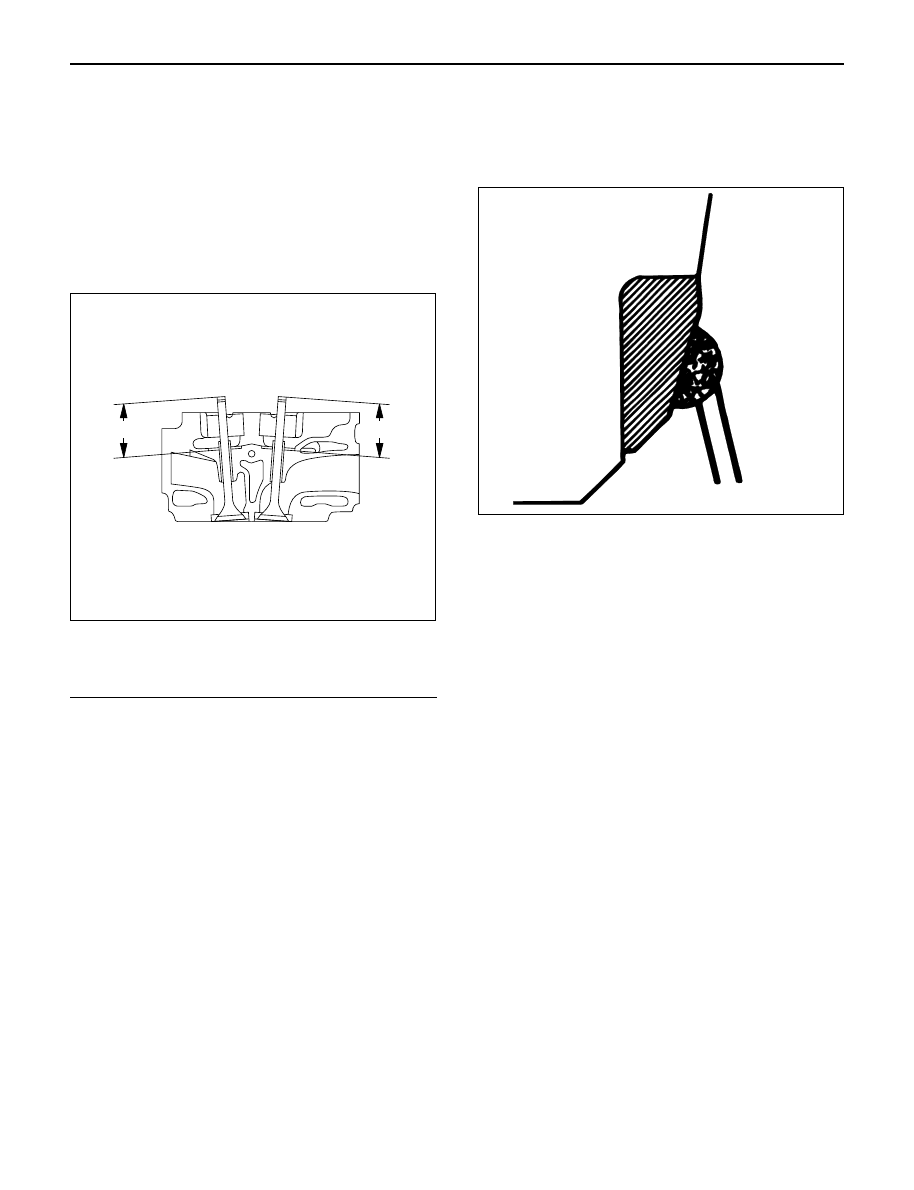

Valve Depression

1. Measure the valve stem height from the upper

surface of the cylinder head as shown in the

illustration.

Standard:

Intake side

35.59 mm (1.4012 in)

Exhaust side 35.49 mm (1.3972 in)

Limit:

Intake side

35.74 mm (1.4071 in)

Exhaust side 35.64 mm (1.4031 in)

Legend

(1) Intake Side

(2) Exhaust Side

Valve Contact Width

1. Check the valve contact faces for roughness and

unevenness. Make the valve contact surfaces

smooth.

2. Measure the valve contact width.

If the measured value exceeds the specified limit,

the valve seat insert must be replaced.

Inlet

Standard: 2.1 mm (0.0827 in)

Limit: 2.6 mm (0.1024 in)

Exhaust

Standard: 2.0 mm (0.0787 in)

Limit: 2.5 mm (0.0984 in)

Valve Seat Insert Replacement

Valve Seat Insert Removal

1. Arc weld the entire inside circumference of the

valve seat insert.

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the

valve seat insert easier.

3. Use a screwdriver to pry the valve seat insert free.

Take care not to damage the cylinder head.

4. Carefully remove carbon and other foreign material

from the cylinder head insert bore.

1

2

011RW044

014RS015