DAF CF65, CF75, CF85 Series . Manual - part 912

©

200423

2-33

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΧΦ65/75/85 series

6

5

2.

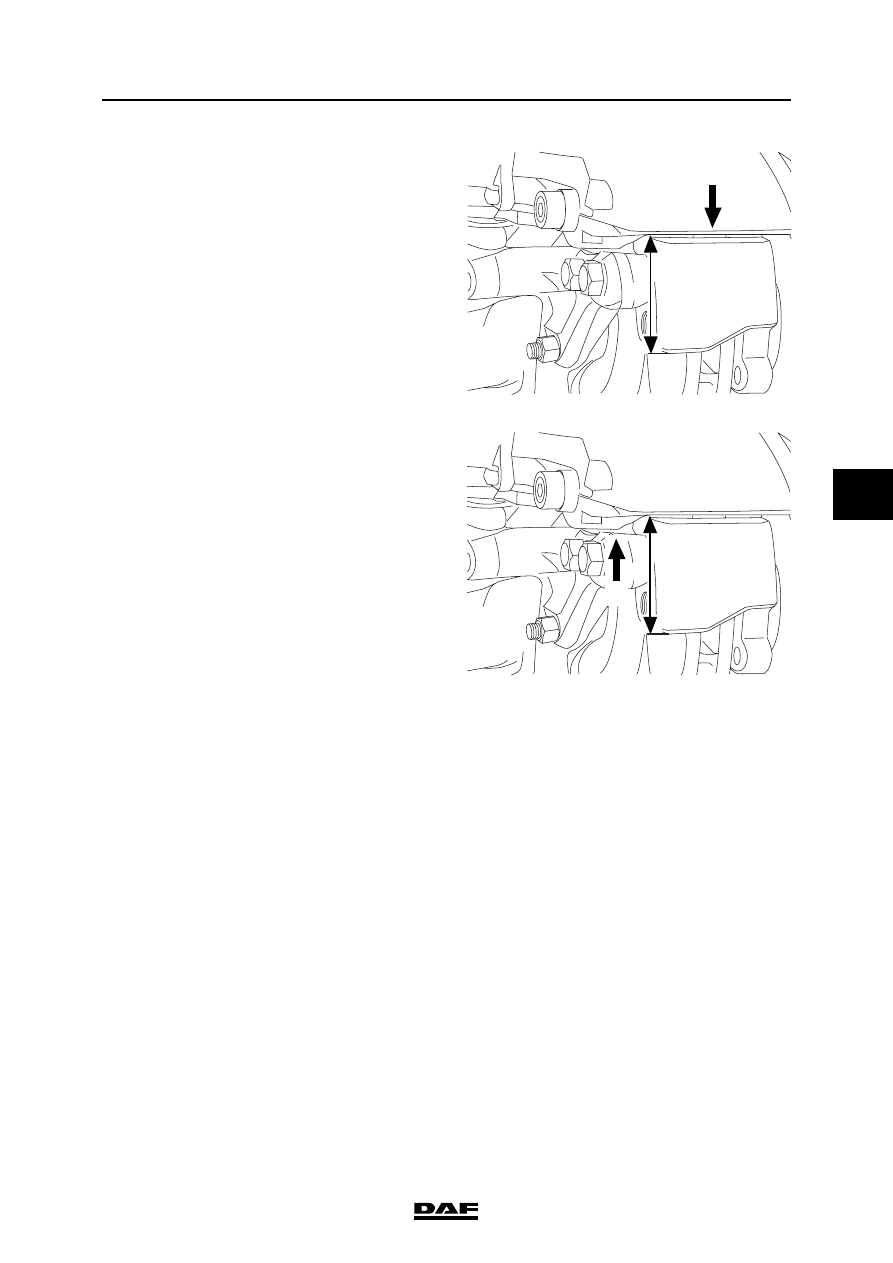

Push the brake calliper as far as possible

towards the brake calliper support (C).

3.

Measure the distance "X".

4.

Push the reversed brake calliper as far as

possible towards the brake calliper

support (D).

5.

Measure the distance "Y".

6.

Calculate the difference between

the measured distances, "Y" - "X"

(see "Technical data").

7.

Fit the brake pads.

X

R600710

C

Y

R600711

D