DAF CF65, CF75, CF85 Series . Manual - part 910

©

200423

2-25

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΧΦ65/75/85 series

6

5

2.17 INSPECTION, BRAKE DRUMS

For reasons of preservation, brake drums of new

vehicles must be cleaned with a cleaning agent.

The brake drums must be lifted using a hoist.

This is because there is a risk of limbs getting

trapped.

Always be careful when braking with new brake

drums and brake linings.

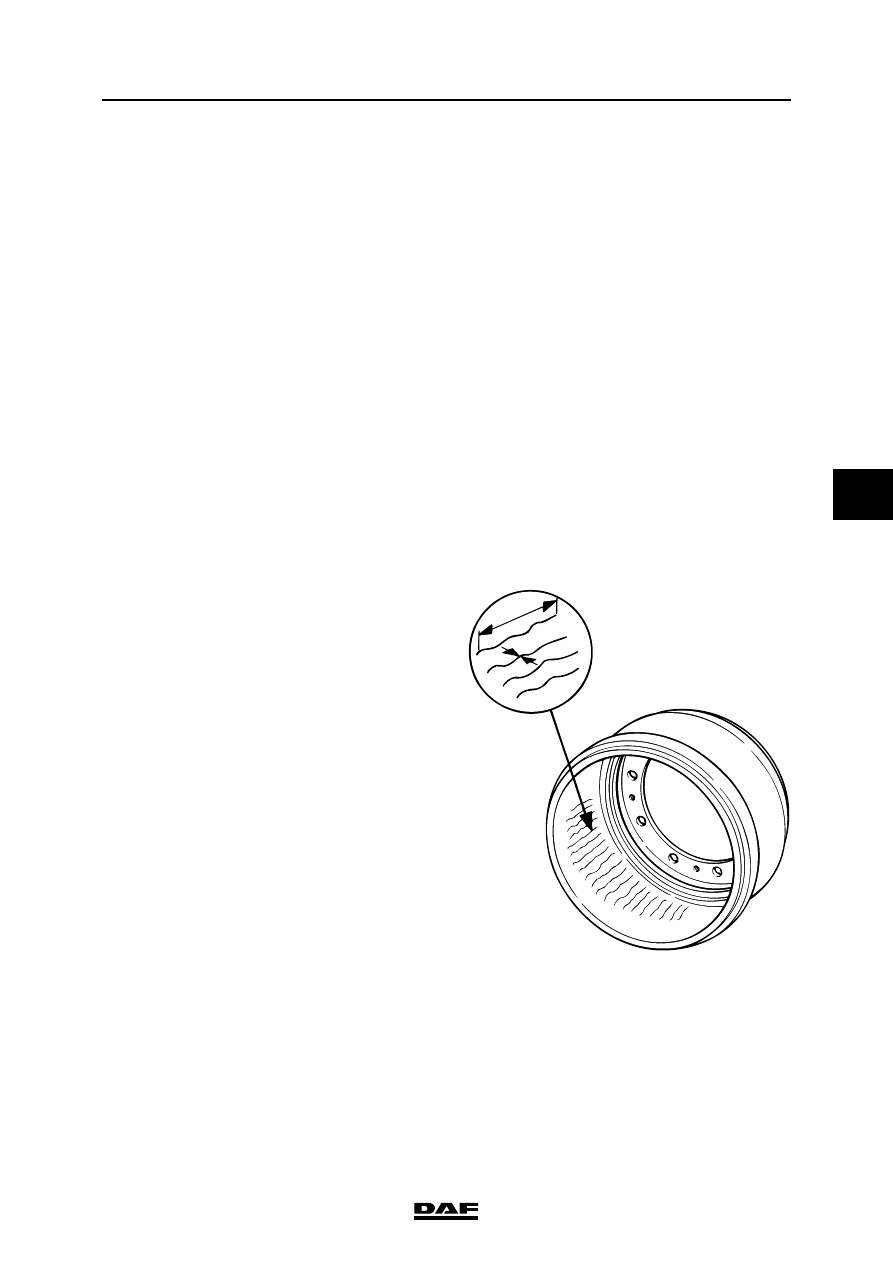

A brake drum which is thermally overloaded will

show heat cracks. These heat cracks will become

larger and deeper the longer the drum is used.

Thermal stress will thus increase the formation of

cracks.

Thermal stress may be caused by:

-

poor braking force distribution

-

seized brakes

-

jammed brake shafts or brake cylinders

-

insufficient clearance between brake lining

and brake drum with new brake linings

-

continuous application of the service brake

whilst driving.

Cracks that are permissible must be capable of

being removed when the drum is reconditioned.

See "Technical data".

If the cracks cannot be completely removed

during reconditioning of the brake drums,

accelerated brake lining wear can be expected.

If the brakes are once again thermally

overloaded, the edges of the cracks will rise

again, which will result in premature wear of the

lining, due to abrasion.

A brake drum may also show burns and local

hardened spots, also caused by high

temperatures.

Where the structure of the brake drum material

has changed, these burns must be removed by

reconditioning and grinding.

If the spots cannot be removed, braking will

always be accompanied by vibrations.

The brake linings will always first show rough

wear grooves at the respective spots.

A brake drum may be used until the internal

diameter has reached the maximum value.

See "Technical data".

As soon as this diameter is exceeded, the brake

drum must be replaced.

R 6 00 128

50

0.7