DAF CF65, CF75, CF85 Series . Manual - part 911

©

200423

2-29

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΧΦ65/75/85 series

6

5

Glazing of brake linings

"Glazing" is the slow deterioration of the brake

lining's coefficient of friction. This is caused by

very light braking. Assessment of the braking

surface is very difficult.

Glazing only rarely occurs with modern linings.

The wearing surface of the lining collects small

particles of materials having lubricant properties.

Generally, these particles are removed by

braking hard a view times, or by turning the lining.

This creates a new wearing surface.

The stability of the coefficient of friction may vary

considerably, depending on the quality of the

lining.

It is therefore vital that original brake linings be

used at all times.

2.19 INSPECTION, BRAKE PADS

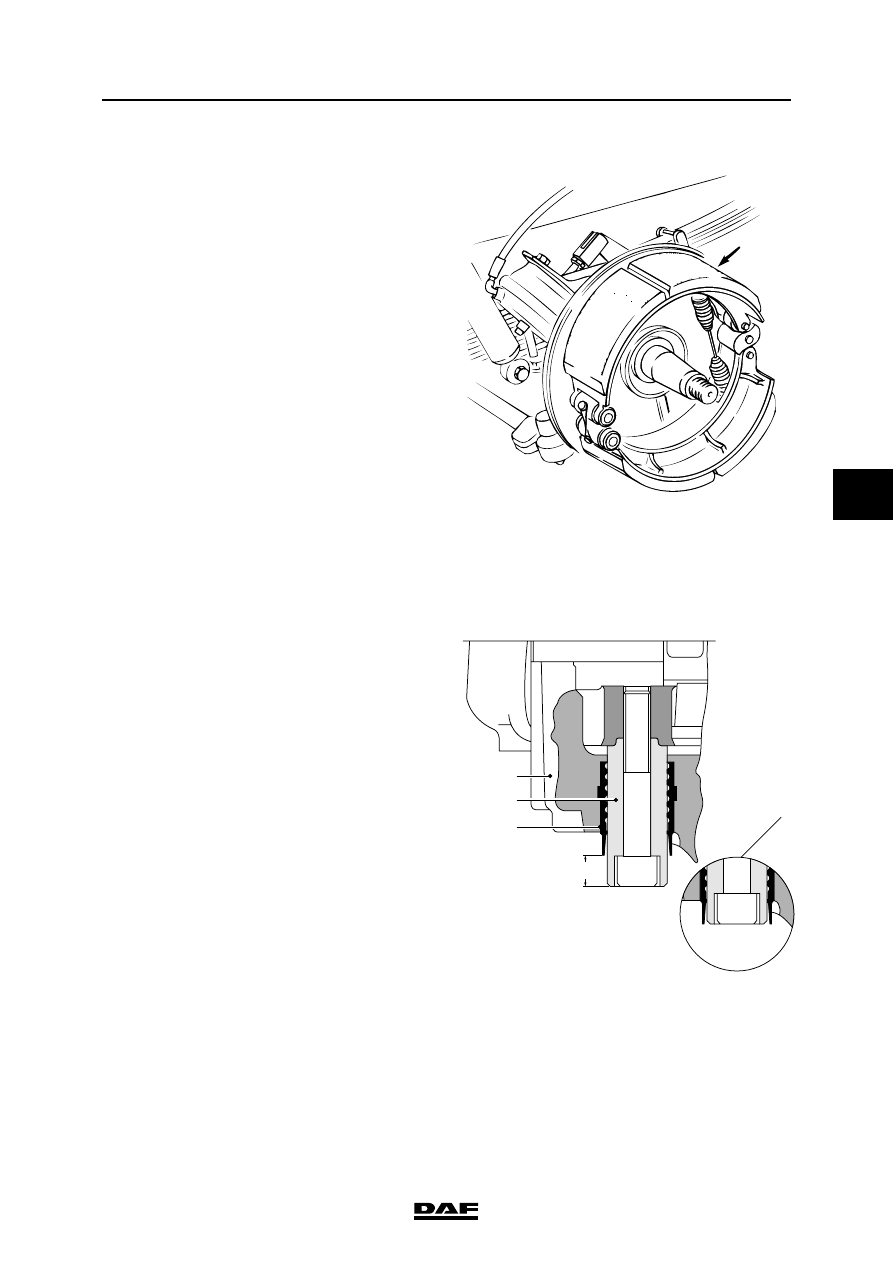

Inspecting Knorr SB7000 brake pads

With wheels fitted:

If the guide sleeve (4) no longer protrudes (C)

from the guide bush (6) but is flush with it

(detail A), the brake pad thickness

must be inspected with the wheels removed.

See "Technical data".

R600132

min. 75%

C

1

4

6

R600481

A