DAF CF65, CF75, CF85 Series . Manual - part 908

©

200423

2-17

Inspection and adjustment

BRAKE SYSTEM AND COMPONENTS

ΧΦ65/75/85 series

6

5

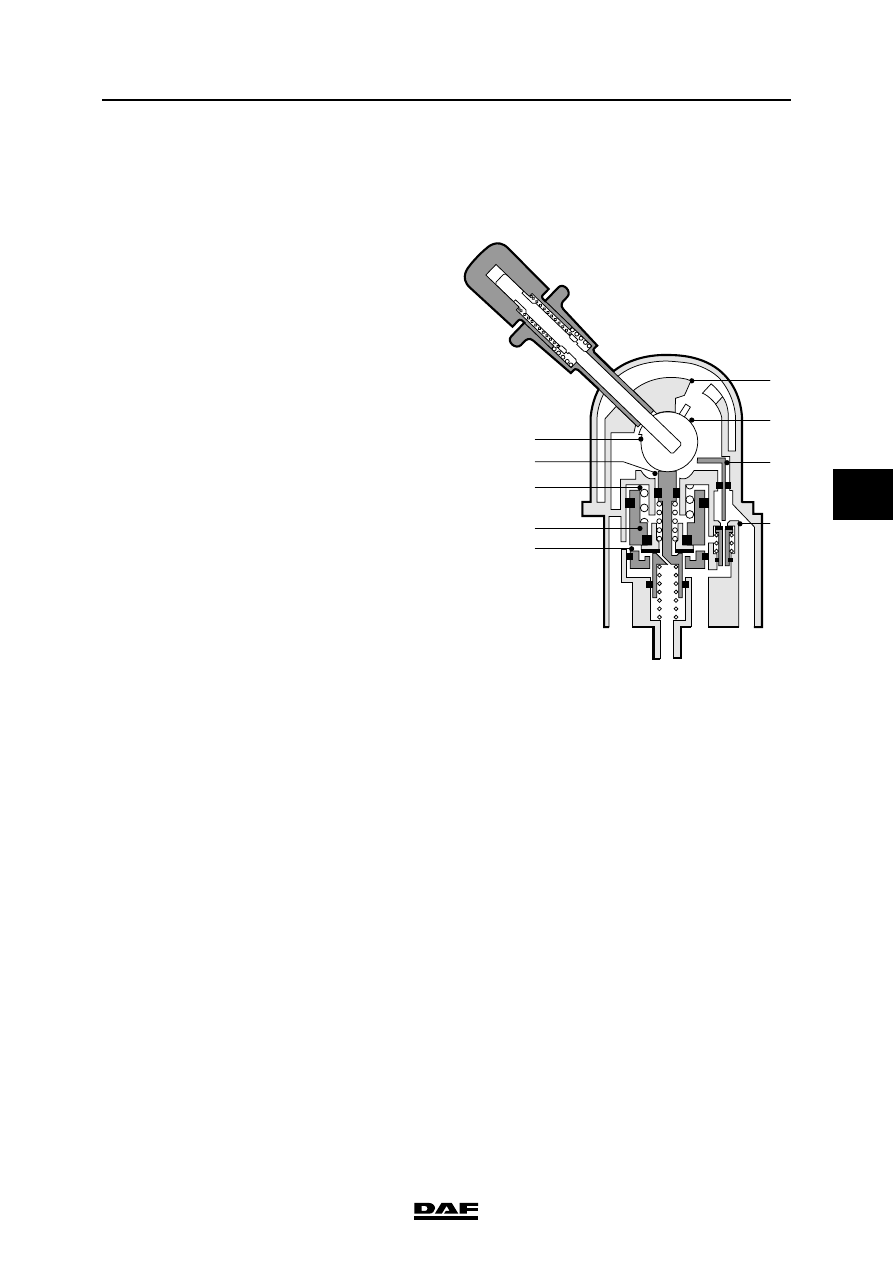

2.11 INSPECTION, PARKING BRAKE VALVE

Parking brake valve with trailer control and

test position

1.

Ensure there is sufficient system pressure.

2.

Connect pressure gauges to connection

point (43) of the trailer control valve and to

connection point (12) of a spring brake

cylinder.

Inspecting the driving position

1.

Place the parking brake valve in the driving

position. Both pressure gauges must now

indicate a pressure of approx. 8.5 bar.

This is the limiting pressure of the pressure

limiting valve.

Inspecting the emergency brake

1.

Move the parking brake valve slowly

towards the parking position. Both pressure

gauges should now gradually fall to 0 bar

(with the exception of the first 10

angular

displacement. See graph in

"Technical data").

Inspecting the parking position

1.

In the parking position, both pressure

gauges should read 0 bar.

Inspecting the test position

1.

Place the parking brake valve in the parking

position, depress the handle, and move it to

the test position. The pressure gauge at

connection point (43) of the trailer vehicle

control valve should read approx. 8.5 bar.

The pressure gauge on the connection

point of the spring brake cylinder should read

0 bar.

3

21

1

22

a

2

3

5

4

6

8

7

9

10

R600092