Content .. 1154 1155 1156 1157 ..

DAF CF65, CF75, CF85 Series . Manual - part 1156

©

200423

3-7

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΧΦ75 series

5

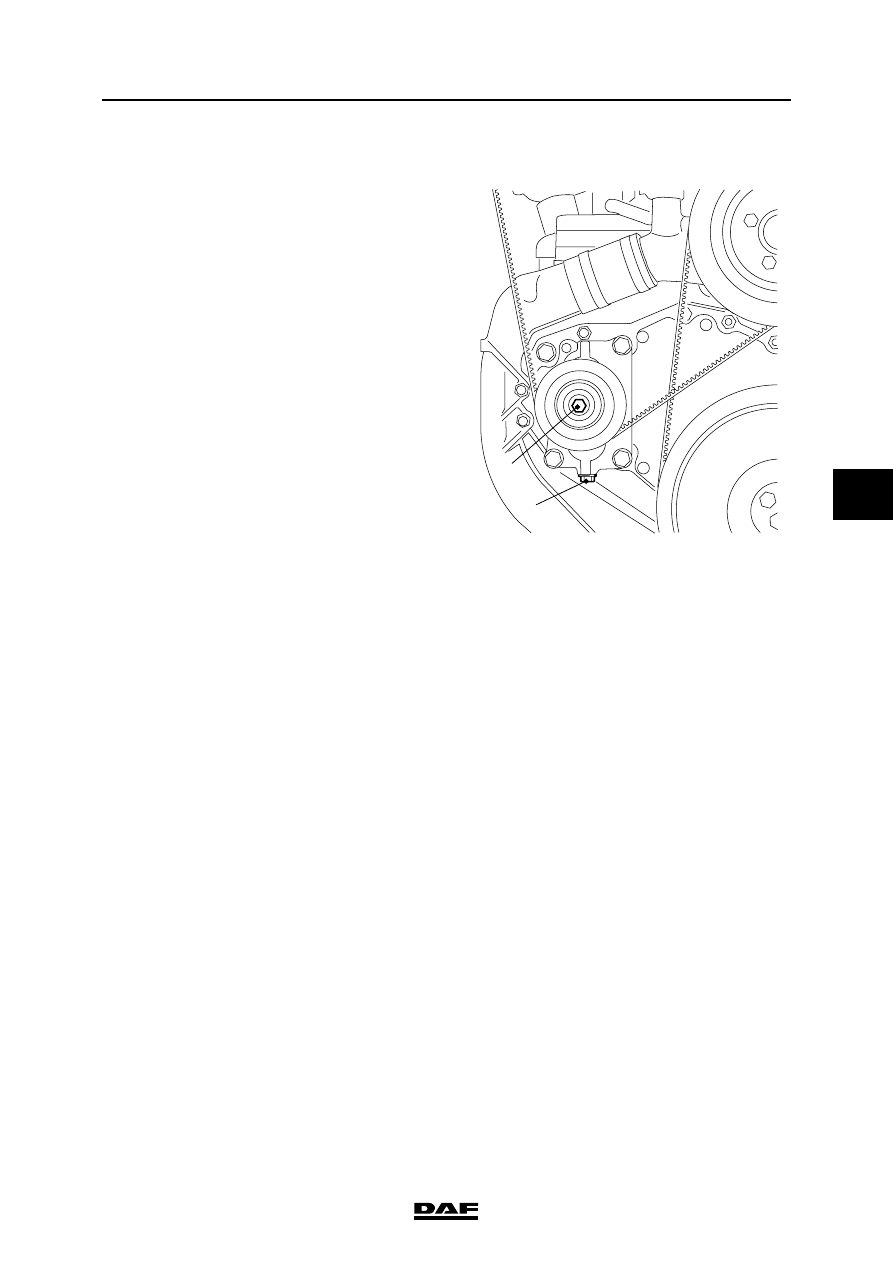

Adjusting the V-belt tension of air

conditioning compressor drive

1.

Slacken the central bolt (1) of the tensioning

roller.

2.

Turn the adjusting screw (2) until the V-belt

tension is correct. See "Technical data".

3.

Tighten the central bolt (1).

1

2

M200885