DAF XF105. Manual - part 97

1

©

200528

3-7

Control functions

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

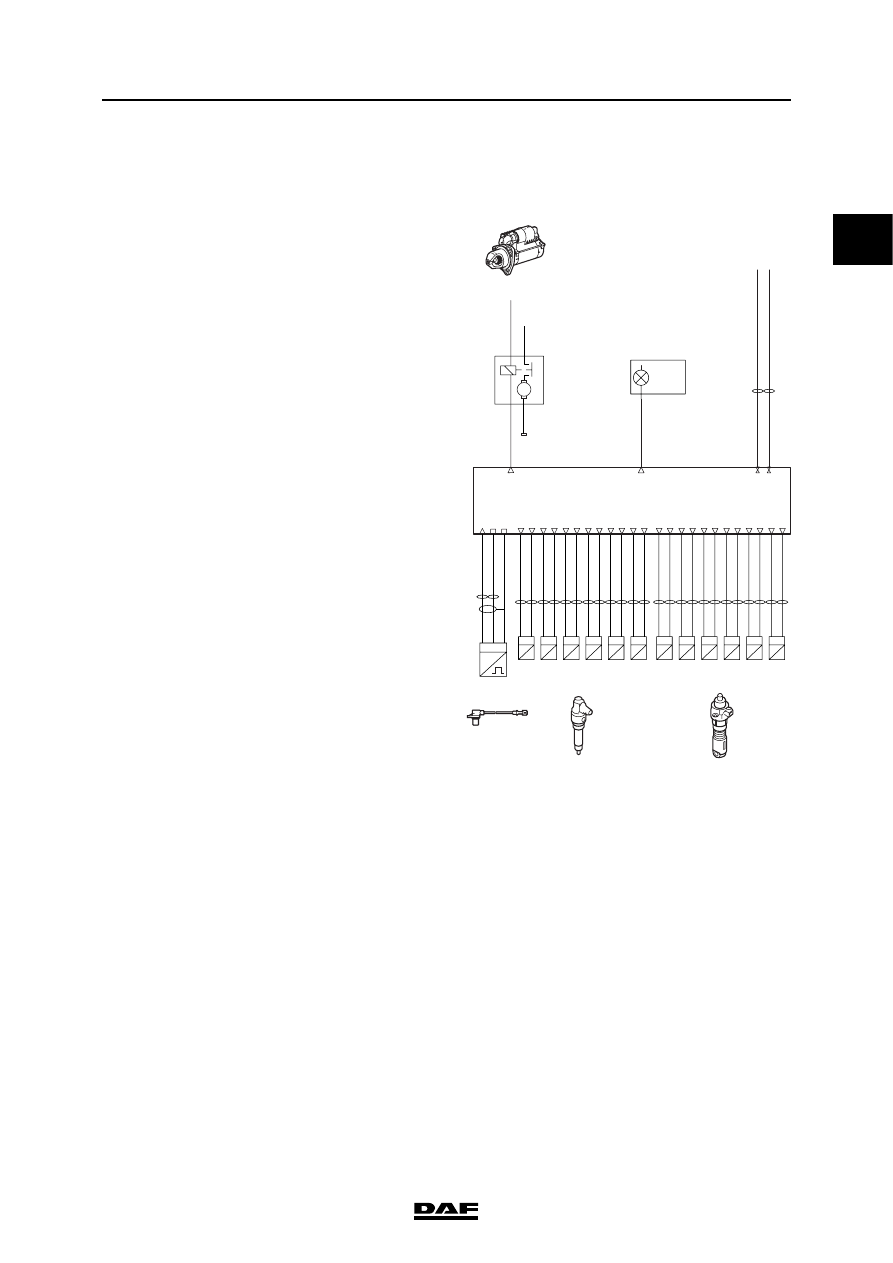

3.4 IMMOBILISER AND START INTERRUPTION

The complete control consists of three functions:

-

Fuel release immobiliser

-

Starter motor block immobiliser

-

Starter motor block if engine is running

Immobiliser

The task of the engine management system in

the immobiliser system is to release and block the

fuel supply and to block the starter motor. The

purpose of the immobiliser is to ensure that the

engine can only be started with the correct

ignition key.

When the vehicle ignition is turned on, the

immobiliser electronic unit reads the immocode

from the ignition key and compares this to the

codes (up to 5) stored in its memory. If the code

is correct, the immobiliser electronic unit creates

a coded CAN message and sends this via

V-CAN1 to the DMCI electronic unit (D965). The

DMCI electronic unit decrypts this CAN message

using the stored vehicle code. If the vehicle code

from the DMCI electronic unit and the vehicle

code from the immobiliser electronic unit are

identical, the CAN message is "approved".

The DMCI electronic unit releases the fuel supply

by on-going control of the pump units and

injectors.

If the codes do not match or there is a fault on the

CAN connection, the DMCI electronic unit will

block release of the fuel supply. The pump units

and injectors will then no longer be activated. The

DMCI electronic unit then informs the immobiliser

unit that the code was not correct and a fault code

is stored in the DMCI electronic unit and the

immobiliser electronic unit.

On the second attempt to start the DMCI will not

earth the starter motor (B010) via B09. The

starter motor will therefore not work.

If release of the fuel supply is blocked, a red fault

message is activated on the DIP master display,

the "STOP" lamp lights up and an acoustic signal

sounds. This message is sent via a CAN

message and output B22 to VIC-2.

i400993

1 2

high-side

low-side

Cyl.6

B136

1 2

high-side

low-side

Cyl.5

B135

1 2

high-side

low-side

Cyl.4

B134

1 2

high-side

low-side

Cyl.3

B133

1 2

high-side

low-side

Cyl.2

B132

A3

A7

A12

A23

A24

A15

A8

A19

A16

A4

A11

A20

1 2

high-side

low-side

Cyl.1

Pump units

B131

1 2

high-side

low-side

Cyl.6

B426

1 2

high-side

low-side

Cyl.5

B425

1 2

high-side

low-side

Cyl.4

B424

1 2

high-side

low-side

Cyl.3

B423

1 2

high-side

low-side

Cyl.2

B422

1 2

high-side

low-side

Cyl.1

Injectors

B421

A2

A8

A9

A22

A21

A14

A5

A18

A13

A1

A10

A17

Vehicle

CAN1

low

Vehicle

CAN1

high

CAN1 low

CAN1 high

B35

B27

B09

flywheel housing

ground

Starter

motor

To battery +

To start

connector

B010

50a

50 30

31

M

B22

C20

+

D310

engine

warning

RED

VIC-2

shield

N

2 1

signal

return

3

F552

speed

crankshaft

A49

A50

A60