DAF XF105. Manual - part 98

1

©

200528

3-11

Control functions

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

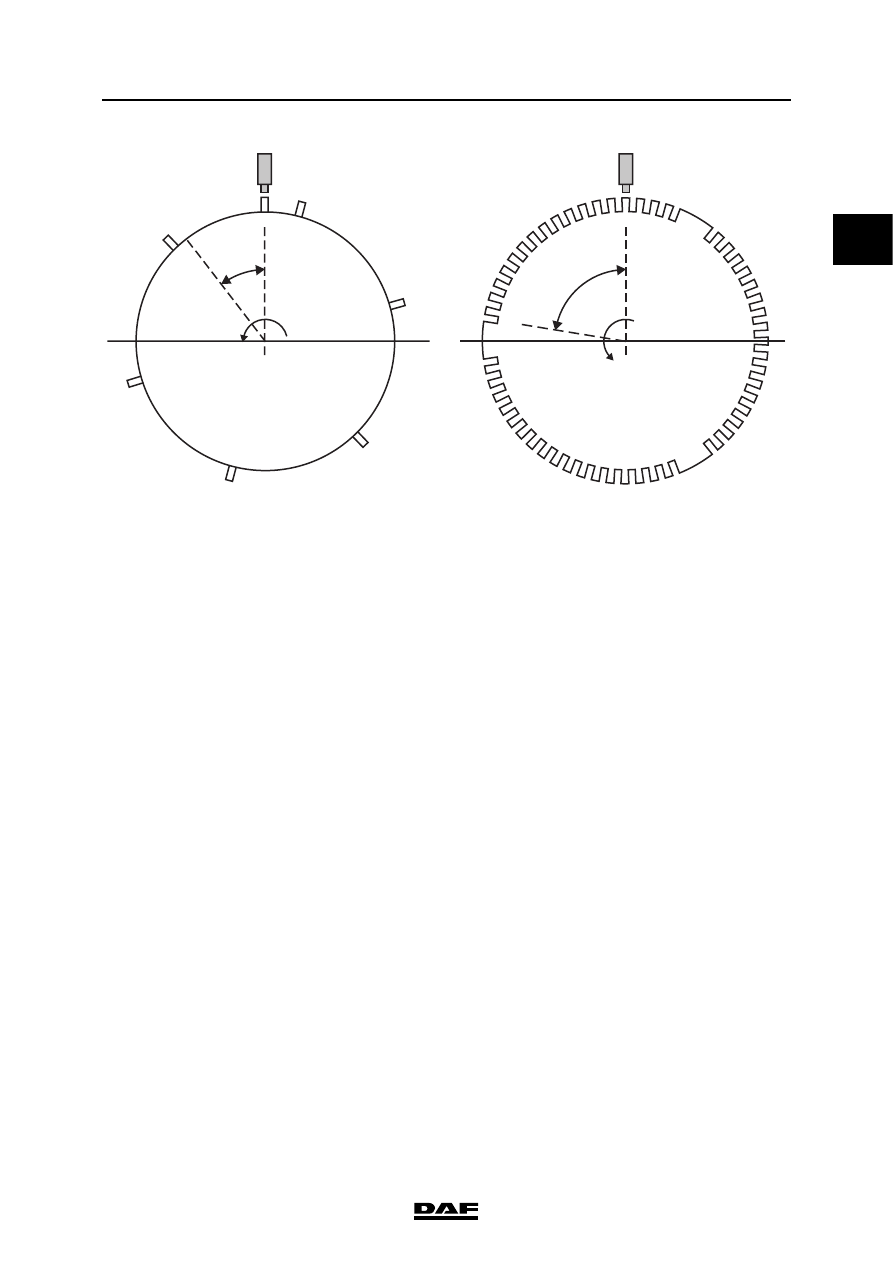

Synchronisation is complete when a camshaft

pulse is sent by the camshaft sensor between the

14

th

and 15

th

pulse of the crankshaft signal. This

pulse is the synchronisation pulse (S). The

synchronisation pulse must be detected within

two crankshaft revolutions. If this is not the case,

this indicates that something is wrong with the

timing of the engine (mechanical fault) or with the

sensor signals (electrical fault). If one of the

sensor signals is absent, synchronisation cannot

take place.

CRANK

CAM

13

1

18

18

15

14

5

1

S

3

6

2

4

i400709