DAF XF105. Manual - part 96

1

©

200528

3-3

Control functions

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

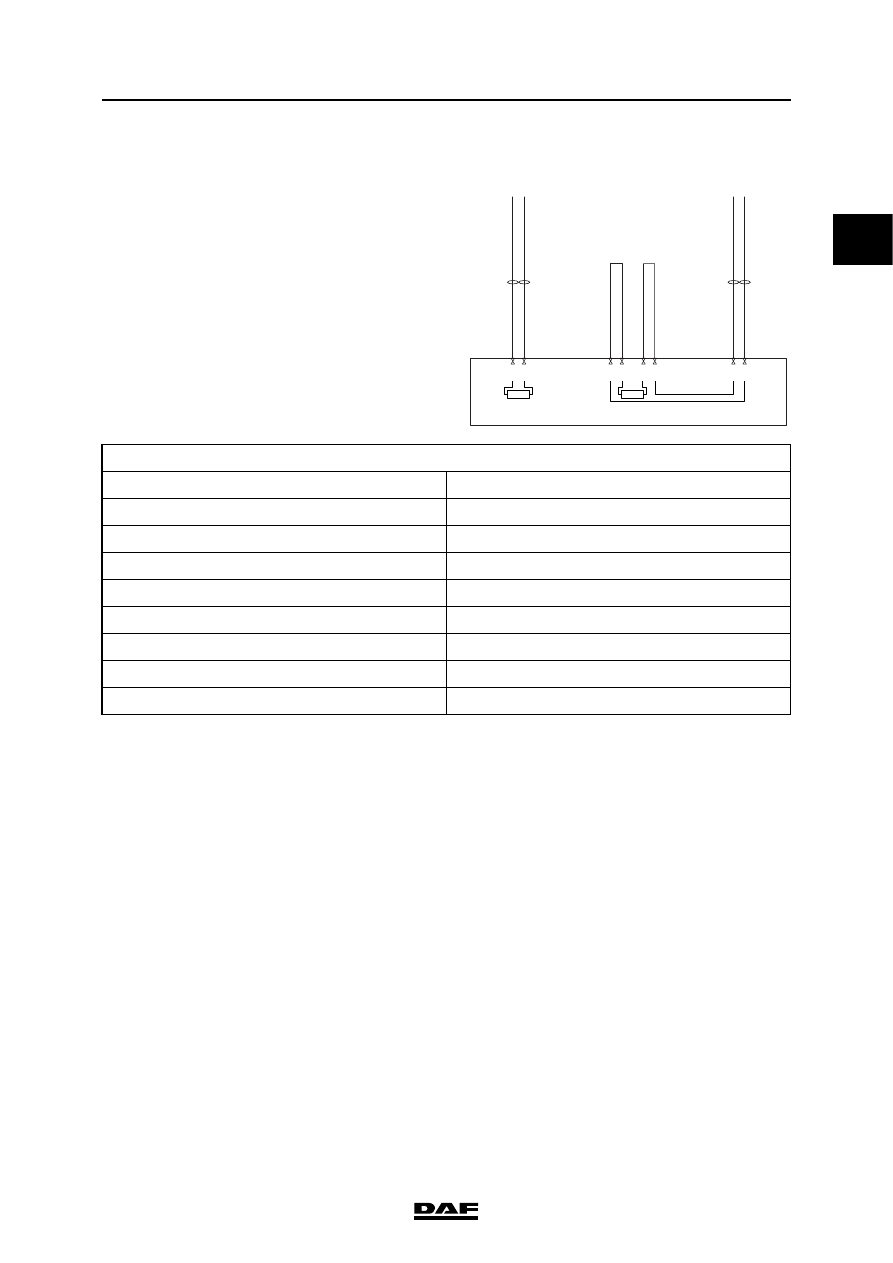

3.2 CAN CONTROLS

The DMCI engine management system

communicates via V-CAN1 and V-CAN2 with

various vehicle systems. DMCI is equipped with a

terminating resistor for V-CAN1 and V-CAN2.

The DMCI electronic unit receives relevant

information from other electronic units and sends

information to these electronic units in its turn.

Communication with DAVIE XD takes place via

the D-CAN to VIC-2 and via VIC-2 and V-CAN1

again to DMCI.

A number of important CAN messages are shown

below.

i400994

Vehicle

CAN2-low

Vehicle

CAN2-high

CAN2 low

CAN2 high

B42

B46

B53

B45

Vehicle

CAN1-low

Vehicle

CAN1-high

CAN1 low

CAN1 high

B35

B27

B50

B54

R

R

D965

DMCI

V-CAN1

V-CAN2

VIC-2

VIC-2

EAS

DIP-4

AS Tronic

BBM

Immobiliser

MTCO / DTCO

ZF retarder EST-42

ABS-D

EBS-2

ECAS-4