DAF XF105. Manual - part 94

1

©

200528

2-25

Description of components

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

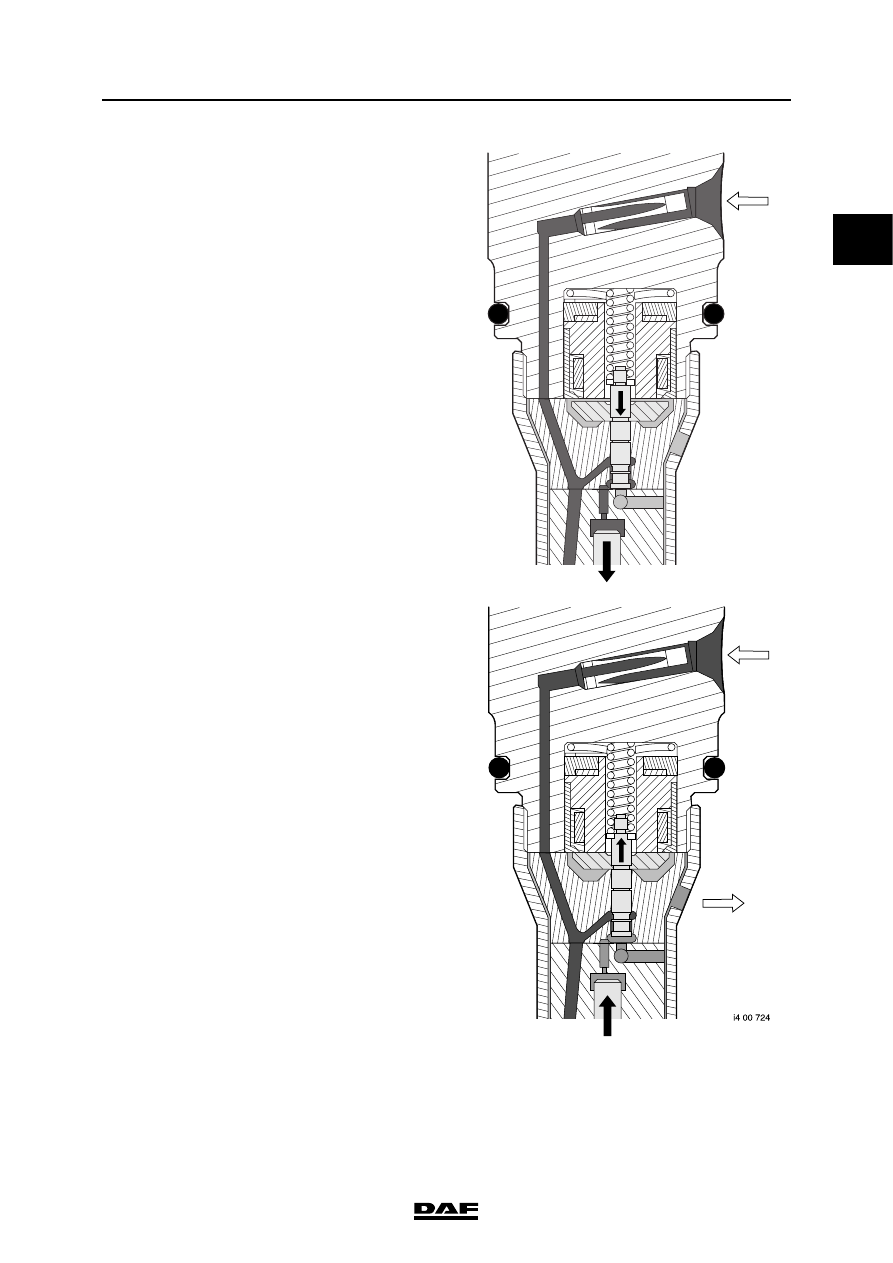

Even though fuel is now being supplied to the

injector, this does not mean that it immediately

starts injecting. The same fuel pressure that must

lift the injector needle also pushes down the

plunger - along with the plunger spring. The

injector needle cannot yet be lifted.

When the coil is activated by the electronic unit,

the valve is pulled in against the pressure of the

spring and the opening to the return is released.

As a result, the pressure above the plunger

decreases. The fuel pressure under the injector

needle now overcomes the pressure of the spring

above the plunger. The injector needle is lifted

and fuel is injected.

To stop injection, the fuel supply pressure to the

injector is decreased by deactivating the pump

unit. The injector is only deactivated once the fuel

pressure is low enough. This is to allow the

plunger spring to close the injector needle

quickly.

i4 00 723