DAF XF105. Manual - part 92

1

©

200528

2-17

Description of components

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

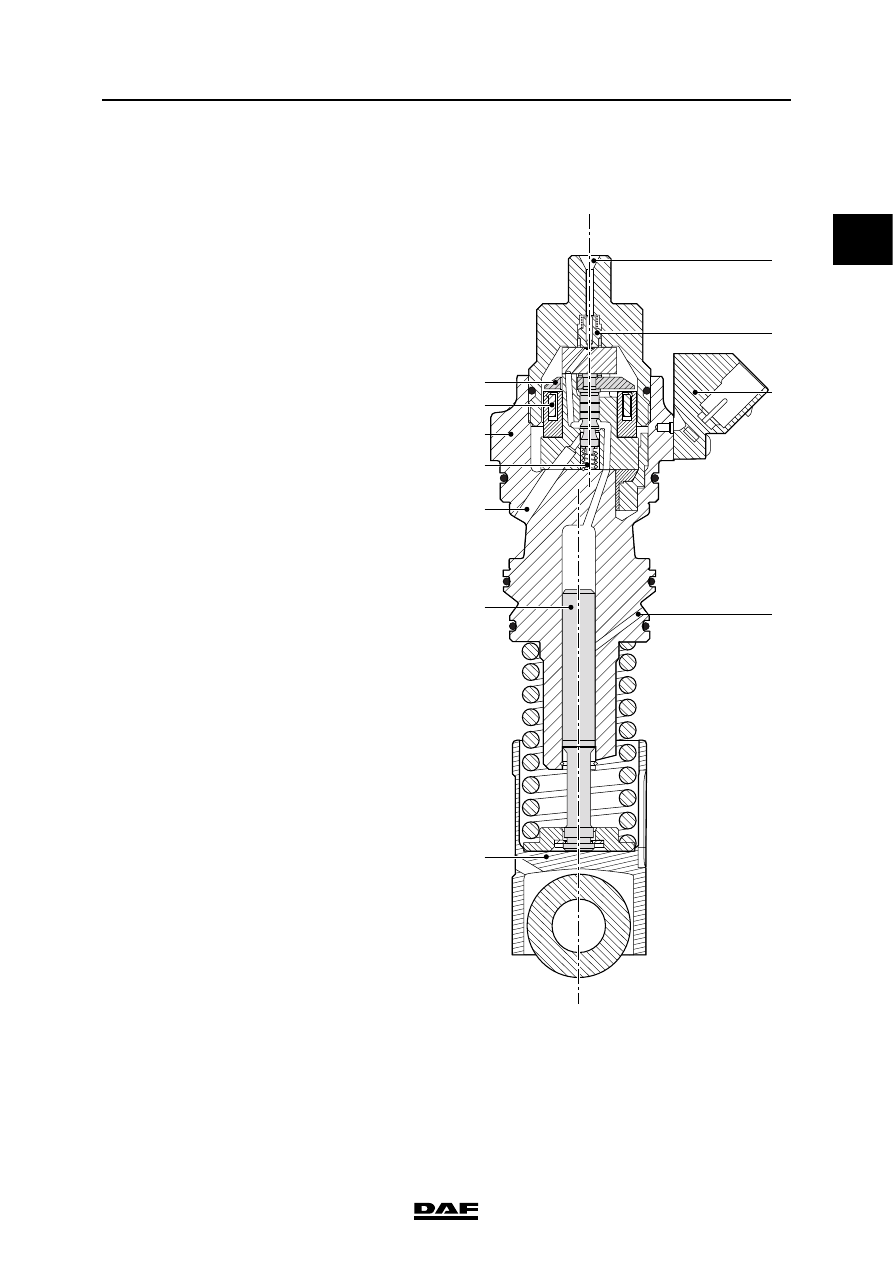

2.11 PUMP UNIT

General

The pump unit supplies fuel to the injector. The

pump unit consists of a metal housing (3) in

which an electrical coil (2) opens a valve (1). In

the rest position, the valve (1) is pushed up by a

spring (4). The electrical connection (8) is

screwed onto the outside of the pump unit. The

roller tappet (6) rotates around the camshaft and

actuates the plunger (5), which builds up the fuel

pressure. The fuel enters the pump unit via the

fuel gallery opening (A). This opening goes into

the fuel supply gallery in the engine block. The

fuel leaves the pump unit in the direction of the

injector via a delivery valve (7). The fuel pipe is

fitted to the injector supply connection (C). Leak-

off/lubricating fuel from the plunger is fed back to

the return gallery in the engine block via the

return opening (B).

B

C

A

1

2

3

4

5

6

8

7

i4 00 714

A.

Fuel gallery opening

B.

Return opening

C.

Injector inlet connection

1.

Lid

2.

Coil

3.

Pump unit housing

4.

Spring

5.

Plunger

6.

Roller tappet

7.

Delivery valve

8.

Electrical connection