DAF XF105. Manual - part 90

1

©

200528

2-9

Description of components

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

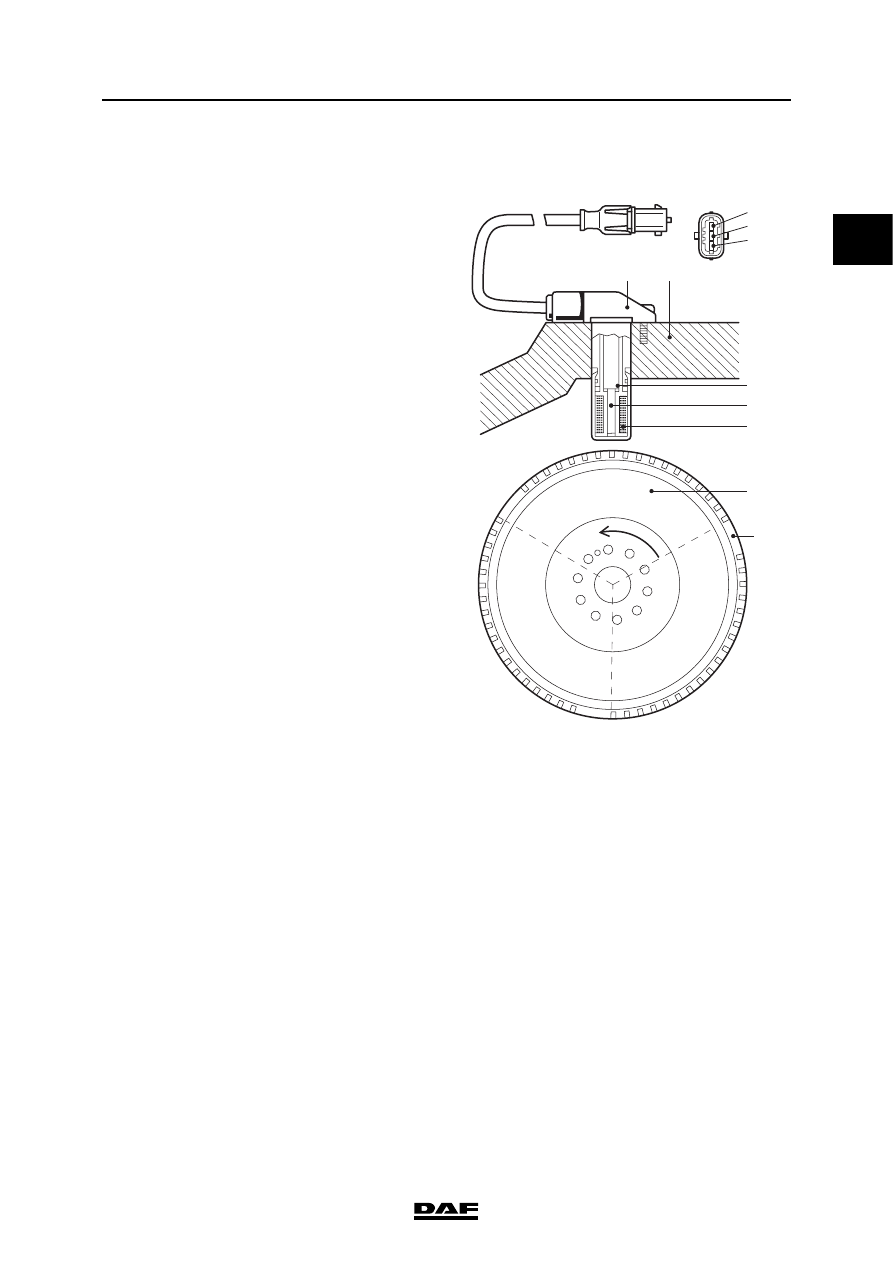

2.8 CRANKSHAFT SENSOR

The crankshaft sensor (F552) registers engine

speed and is used to determine the injection

timing. The crankshaft sensor is responsible,

together with the camshaft sensor, for

synchronisation when starting the engine. If there

is no camshaft signal, the crankshaft signal is

used for cylinder detection.

The crankshaft sensor (A) is mounted on the

flywheel housing (B). It is an inductive sensor and

consists of a magnet (C), a metal core (D) and a

coil (E). Inductive means that the sensor can

generate an alternating voltage signal

independently by means of a changing magnetic

field. The pattern of holes in the flywheel (F)

means that the sensor can generate a specific

alternating signal. The pattern consists of 3

segments each with 18 holes and an area with

2 holes missing (G). Each segment is used for

calculations on two specific cylinders (1/6, 2/5

and 3/4).

The sensor has 3 connections. Pins 1 and 2 are

responsible for the signal. Pin 2 is the signal

connection and pin 1 is the earth connection. Pin

3 is connected to the shield around the signal

wires and to the earth connection (pin 1). This

prevents the engine speed signal being affected

by signals from outside.

1

18

I400731

1

2

3

A

B

N

S

D

C

E

F

G

1

Electrical connection, earth

2

Electrical connection, signal

3

Electrical connection, shield

A

Crankshaft sensor

B

Flywheel housing

C

Magnet

D

Metal core

E

Coil

F

Flywheel

G

Hole pattern