DAF XF105. Manual - part 88

1

©

200528

2-1

Description of components

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

2. DESCRIPTION OF COMPONENTS

2.1 DMCI ELECTRONIC UNIT

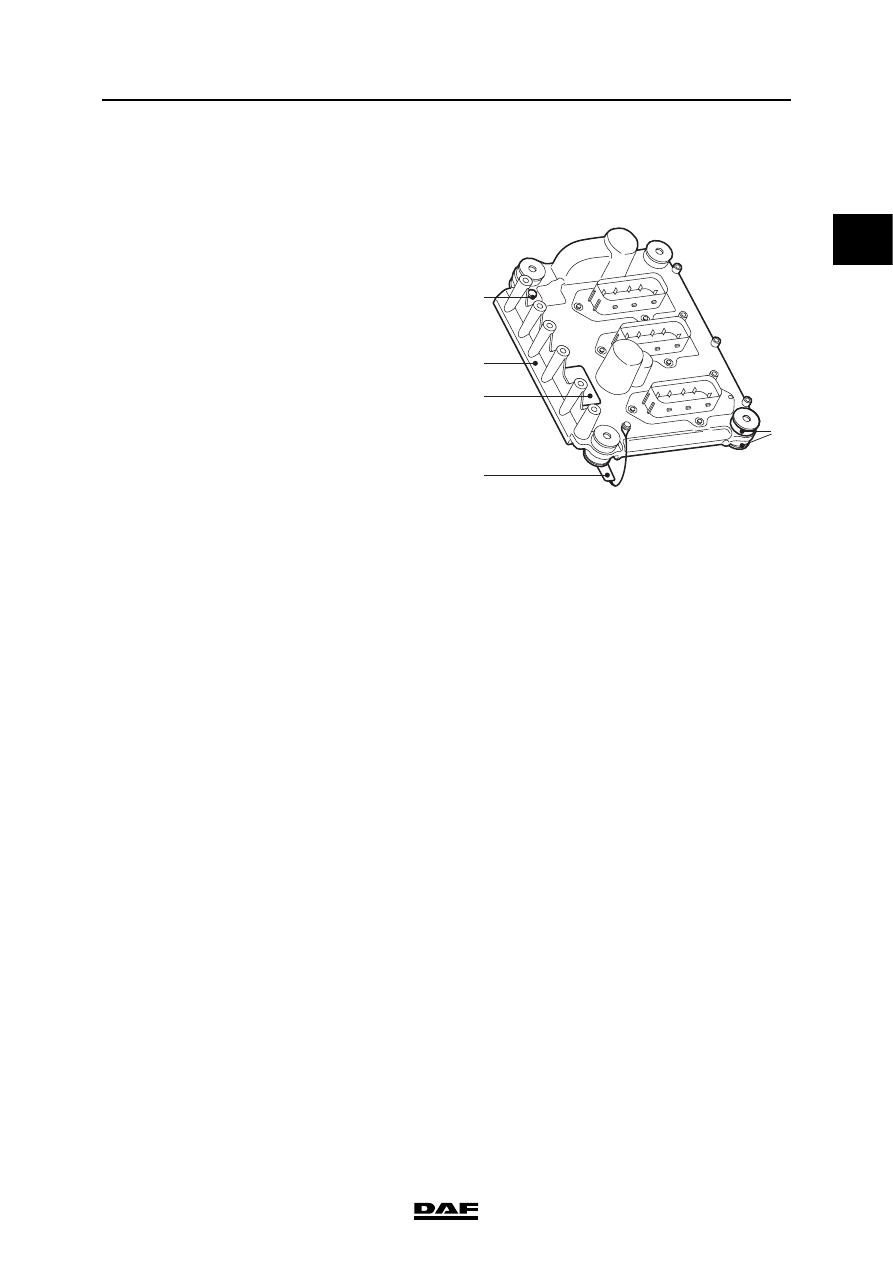

The electronic unit is mounted on the cylinder

block using rubber insulating bushes (3). The

electronic unit has three 62-pin connectors. Input

signals from various sensors are continuously

processed and compared with data stored in

various maps (tables) in the electronic unit.

Actuators are energised on the basis of the

signals received and the maps.

The housing (1) of the electronic unit is directly

connected to the engine block by an earth cable

(2). This earth connection is required because of

internal components which protect against radio

waves from outside.

The electronic unit incorporates an atmospheric

pressure sensor and a temperature sensor.

There is an air vent (4) for the atmospheric

pressure sensor in the housing of the electronic

unit.

An identification sticker (5) is attached to the

electronic unit.

The effect of atmospheric pressure on the

system:

-

the quantity of fuel injected when driving at

high altitudes (low air pressure).

If atmospheric pressure is low (in mountainous

areas), the air is thinner. When the air is thinner it

has a low density. The electronic unit uses this

information to control the turbocharger pressure

and adjust the quantity of fuel to be injected.

The effect of the internal temperature sensor

on the system:

-

none.

The internal temperature sensor measures the

temperature of the electronic unit. If the

temperature becomes too high, a fault code is

stored. The system does not take any further

action on the basis of this information.

Calibration

The performance of pump units and injectors may

differ slightly from one another as a result of small

production tolerances. These small production

differences are compensated for during

production by means of calibration in order to

optimise the engine output, exhaust gas

emissions and handling characteristics. A

calibration code is used to program the pump

units and injectors into the electronic unit

individually. The electronic unit modifies the

control of the pump units and injectors on the

basis of these calibration codes.

i400785

1

5

2

3

4