Content .. 1304 1305 1306 1307 ..

Chevrolet Silverado / GMC Sierra. Manual - part 1306

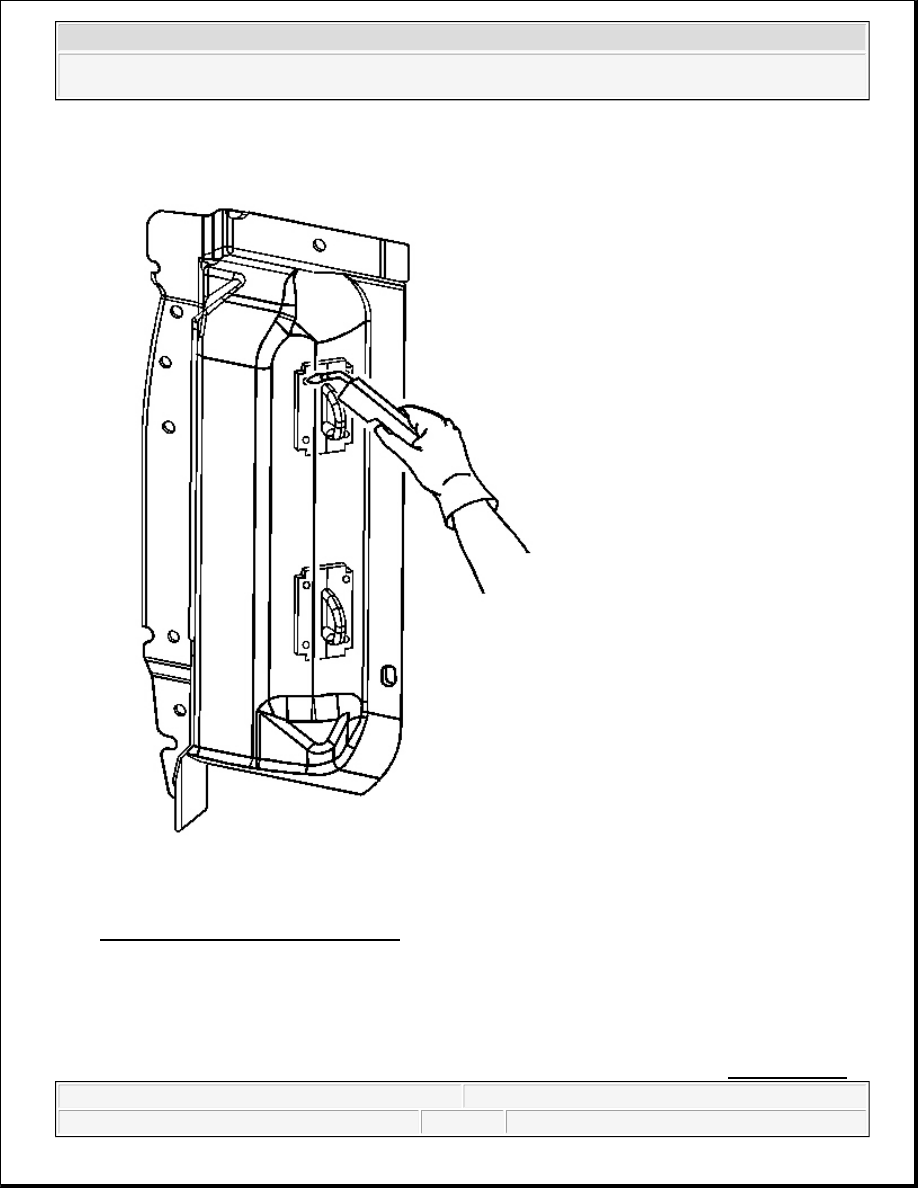

Fig. 138: Plug Welding Tie Down Loop

Courtesy of GENERAL MOTORS CORP.

3. Position the tie down loop.

4. Plug weld accordingly.

5. Clean and prepare all welded surfaces.

6. Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to Anti-Corrosion

2008 Chevrolet Silverado 1500

2008 ACCESSORIES & EQUIPMENT Collision Repair - - Cab & Chassis Sierra, Cab & Chassis Silverado, Sierra &

Silverado

Microsoft

Friday, August 21, 2009 2:21:01 PM

Page 150

© 2005 Mitchell Repair Information Company, LLC.