Haima S5 1.5T. Service Manual - part 8

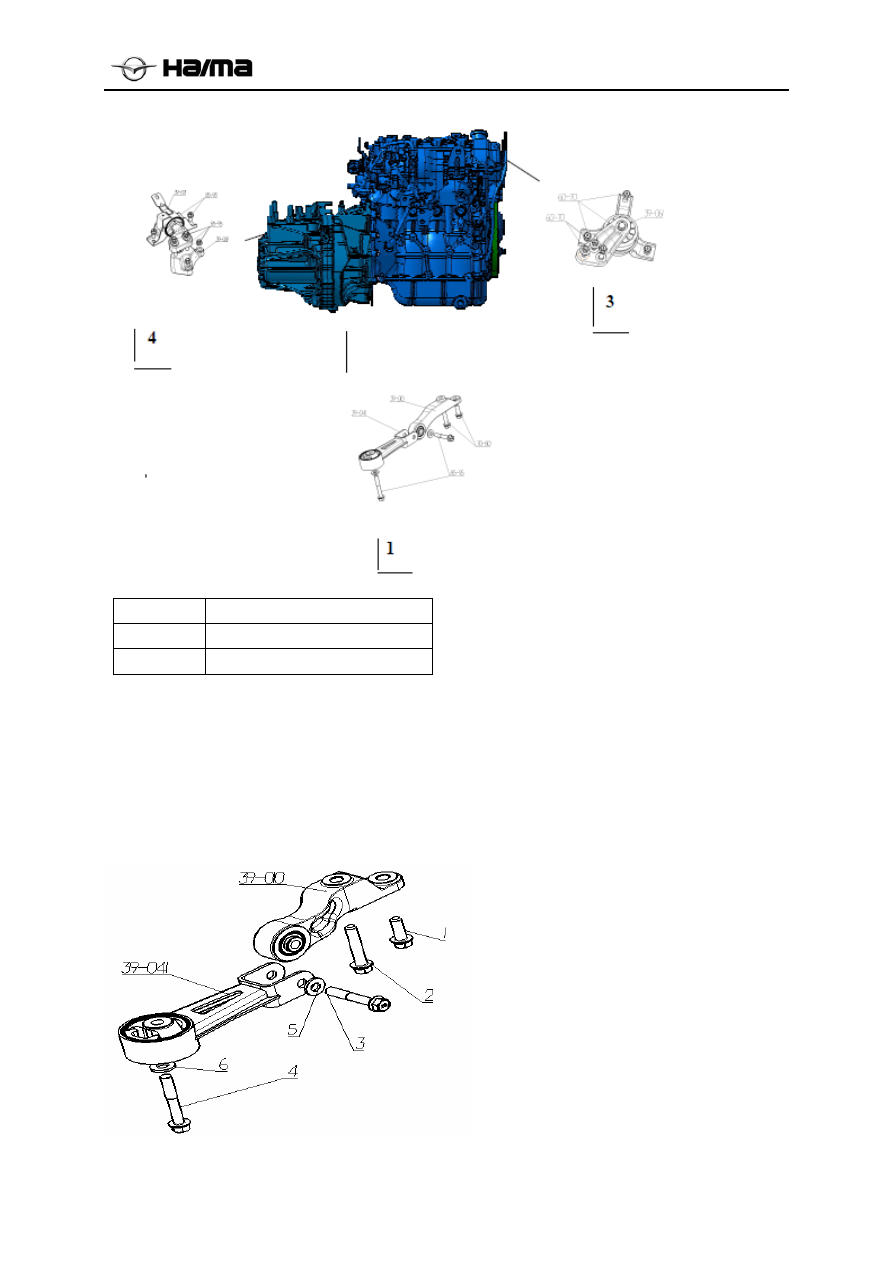

Engine Suspension

1G-3

1 Engine1#

suspension

3 Engine3#

suspension

4 Engine4#

suspension

1.1.1 Engine1# Suspension Bracket Dismantling/ Mounting

1. Dismantle the engine # 1 bracket bolts 1 and 2 (transmission side) ;

2. Remove the engine mounts bolt # 1 flat washer 5 ,3, 4 flat washers and bolts to remove the engine 1# 6;

3. Check rubber mounts broken, hardening or damage.

4. Mount parts according to the sequence reverse to the dismantling process.