Yanmar diesel tractor EF494T. OPERATOR'S MANUAL - part 12

EF494T OM

44

17. Hydraulic

output

CAUTION

Never fail to stop the engine before trying to detach the

hydraulic plug or pipes. Otherwise, you may be injured

by high pressure oil.

Single action cylinder (e.g. dump trailer)

(1) Set the position control lever about 20 mm below the

top position.

(A) Position control lever

(B) About 20 mm

(2) Fasten the hydraulic stop slow-return valve fully

clockwise.

(A) Hydraulic stop slow-return valve

(B) Close

(3) Remove the hydraulic output plug, and connect the

high pressure hose of an implement.

* Keep removed copper packing and plugs.

(A) Hydraulic output plug

NOTE:

3-point rear hitch implement cannot be controlled

by position control lever while stop slow-return

valve is closed.

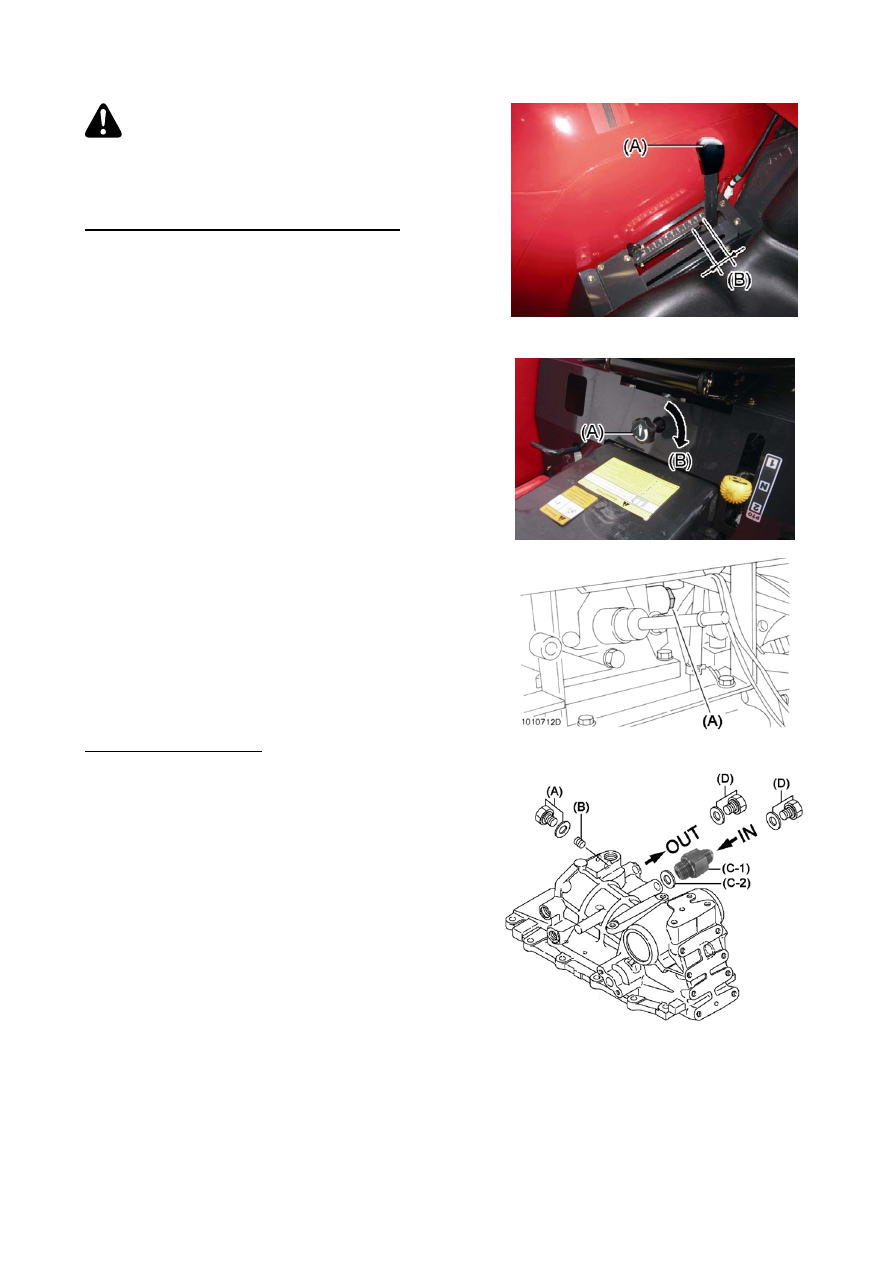

Double action cylinder

(1) Remove the plug (A). Insert and tighten the screw

plug (B) to switch inner hydraulic oil flow.

(2) Remove plugs (D) on the right side of hydraulic

housing. Put the filter adapter (C) to the return port

(IN). Connect the hydraulic valve of implement.

Port at the front side: OUT (to take out)

Port at the rear side: IN (to return)

(A) Plug, 3/4-16UNF

(B) Screw plug, PTF 1/4-18 (198245-42160)

(C-1) Filter adapter, 3/4-16UNF (1A7780-45950)

(C-2) Gasket, 19x1.0 (23414-190000)

(D) Plug, 3/4-16UNF

NOTE:

Rear hitch implement can be controlled by position

control lever.

Keep plug (D) for future reuse.