Yanmar diesel tractor EF494T. OPERATOR'S MANUAL - part 11

EF494T OM

40

10. Driving

in

and out of Fields

WARNING

Always connect the left and right brake pedals with

the connector. Otherwise, one-sided braking can

cause a roll over.

When approaching the field or when crossing a

ditch, use a gangplank of sufficient strength to enter

the field. Lower any implement to reduce the center

of gravity.

Climb a slope backwards, in reverse. Drive down a

slope forward, in low gear.

Before starting to climb a hill, lower any implement.

After the rear wheels are on the ridge (A), you can

lift the implement.

(A) Ridge

11. Setting

an

adequate

speed

9 forward speeds and 9 reverse speeds are available by

the combination of main, range and reverse shift levers.

Use an adequate speed for works referring to the table

below.

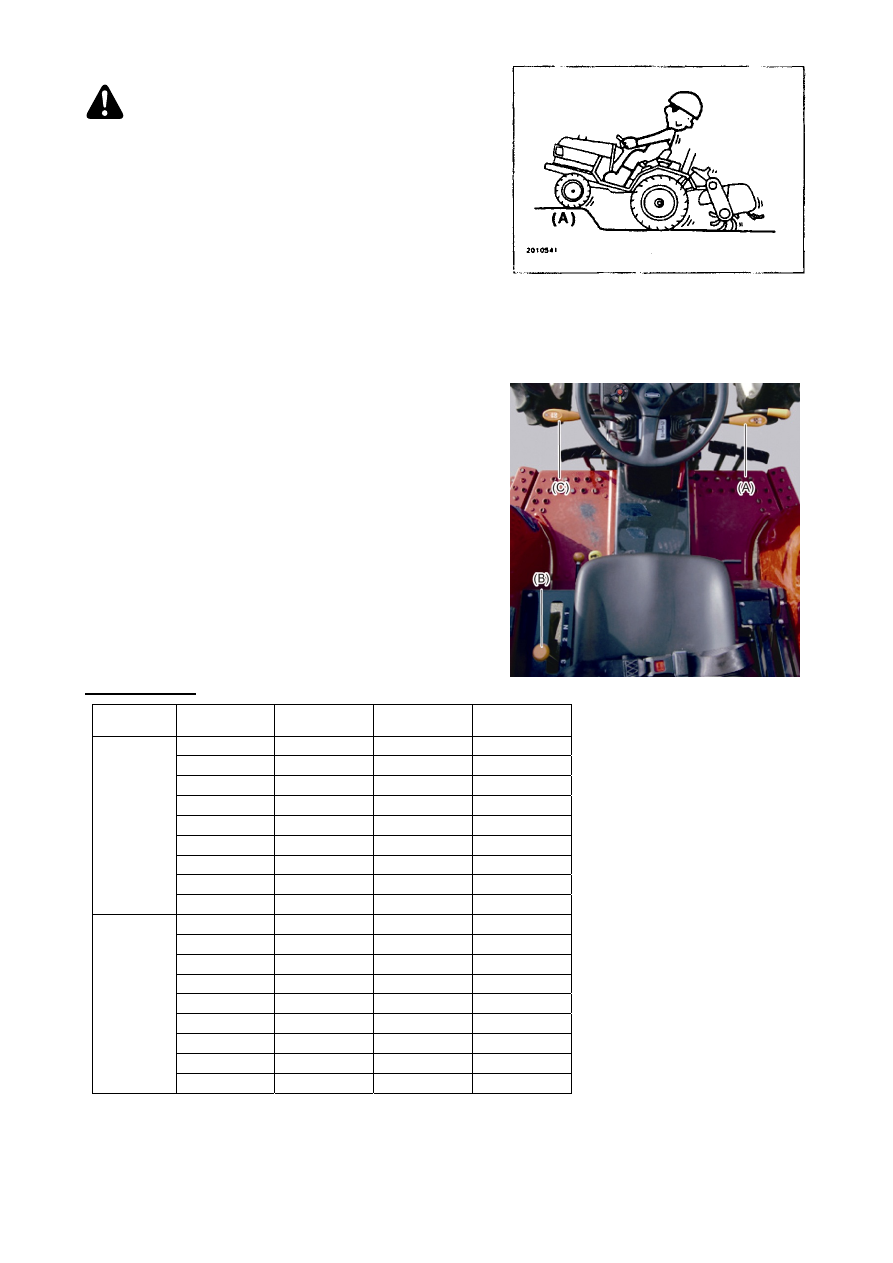

(A) Main shift lever

(B) Range shift lever

(C) Reverse shift lever

Driving Speed

F/R

Shift

position

Main shift

Range shift

km/h

Forward

1 1 1

1.63

2 2 1

2.26

3 3 1

3.30

4 1 2

4.00

5 2 2

5.57

6 3 2

8.14

7 1 3

14.18

8 2 3

19.72

9 3 3

28.80

Reverse

1 1 1

1.68

2 2 1

2.33

3 3 1

3.41

4 1 2

4.13

5 2 2

5.74

6 3 2

8.39

7 1 3

14.62

8 2 3

20.33

9 3 3

29.70