Yanmar diesel tractor EF494T. OPERATOR'S MANUAL - part 13

EF494T OM

48

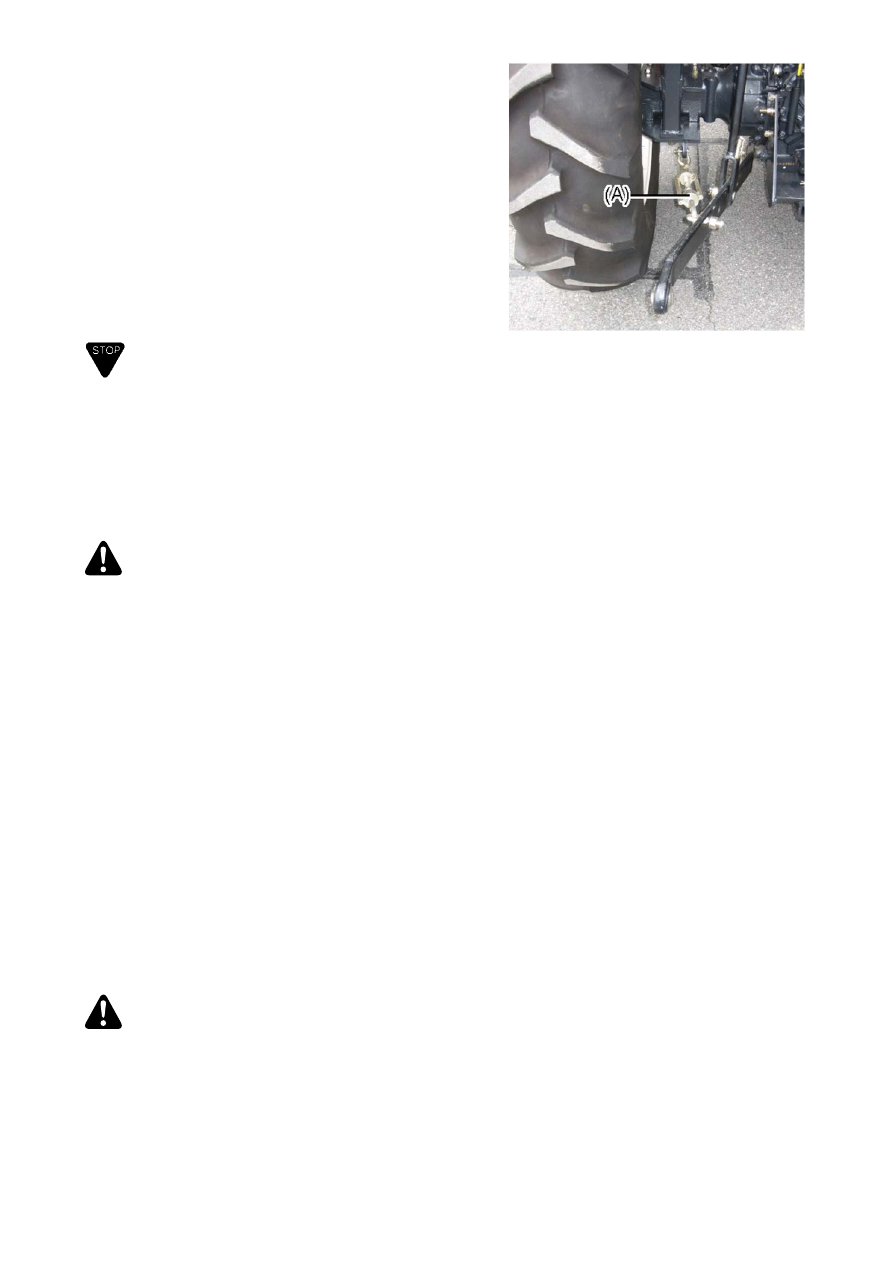

(10) Check chains

Adjust check chains (A).

1) For use of implements such as a plough, harrow and

subsoil, adjust check chains (A) so that an

implement can move 5 - 6 cm to right and left.

Prevent an implement from swinging to hit against

the wheels and tires.

2) For use of implements such as a rotary tiller and

mower, adjust check chains (A) so that an

implement can move 1cm to right and left.

(11) Dismantling is done in the reverse order as the

fixing process.

IMPORTANT

Remove the drawbar if the drawbar interferes with an

implement.

Fasten lower links to prevent from swinging to hit

against wheels and tires when driving the tractor

without an implement.

21.

Notes on using service implement

WARNING

When moving the tractor to mount an implement, never allow a

person or persons between the tractor and the implement.

Mount or dismantle an implement on a flat ground using a safe

method. Use the lighting during nighttime works.

When a heavy implement is mounted on the tractor, apply a

counterbalance to maintain a balanced condition.

Before leaving the tractor for mounting an implement, never fail

to engage the parking brake and stop the engine. Make sure the

PTO shift lever is in N.

For traction work, always use the draw bar. Do not attach to

other parts of the tractor.

Use a wider wheel span for a traction work or works on the

slope.

Do not operate the low speed machines at a higher speed than

the rated. Maintain the rated PTO speed.

When drawing a trailer, interlock the trailer brake with the tractor

brake. Do not change the shift on the slope.

Mounting an implement machine results in a considerable overall

length; be careful not to hit farmers or constructions in the

vicinity.

Negligence of safety precautions may cause serious injury

or death.

WARNING

Running the PTO speed below or above the rated operating speed of

the implement may cause damage to the tractor or the implement.