Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 232

6C–8

ENGINE FUEL (6VE1 3.5L)

Fuel Tube / Quick – Connector Fittings

Precautions

D

Do not light a match or create a flame.

D

Keep flames away from your work area to prevent

flammable materials from catching fire.

D

Disconnect battery ground cable to prevent electrical

shorts.

D

Pre-treat piping system or associated parts from

thermal damage or from spattering when welding or

similar heat-generating work.

Cautions During Work

140R100032

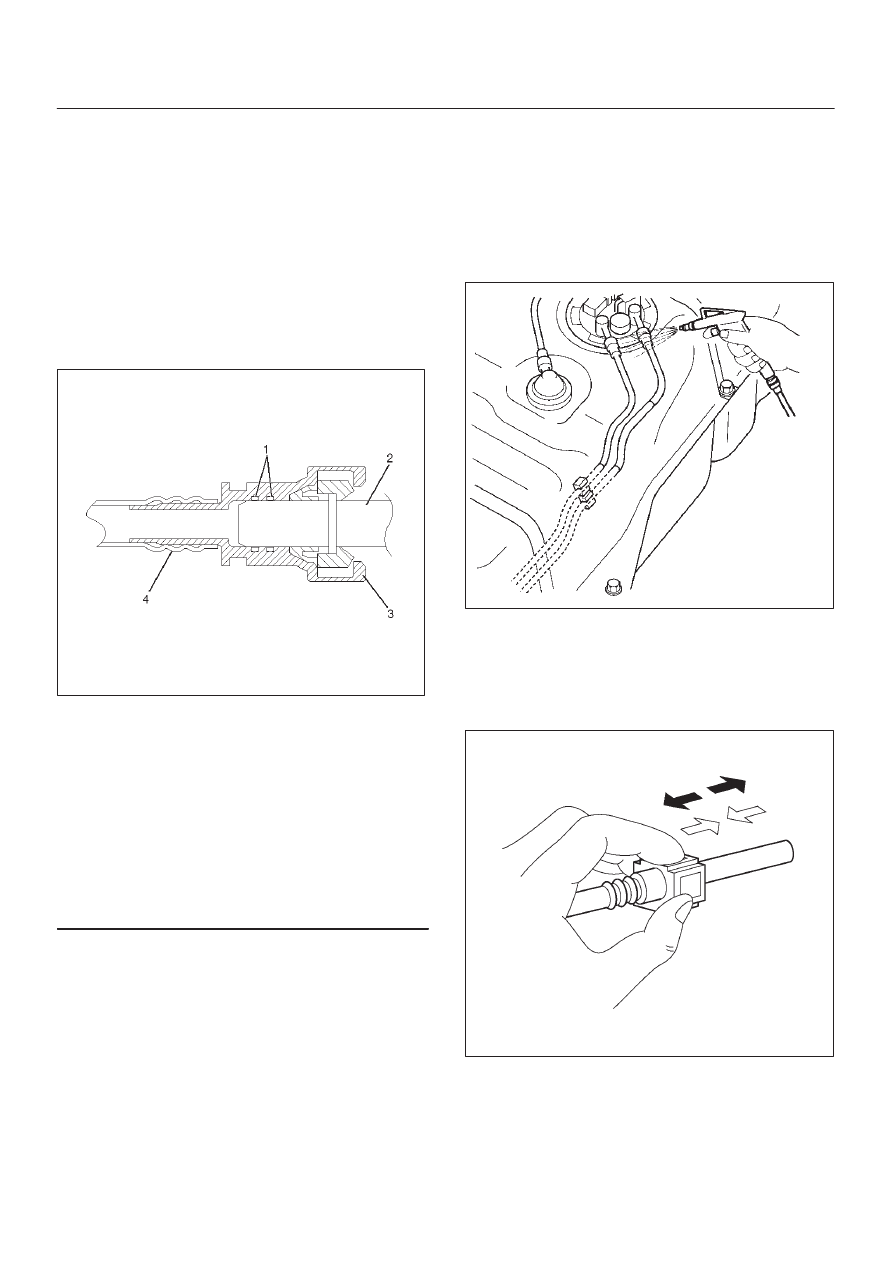

Legend

(1) O-ring

(2) Port

(3) Connector

(4) Plastic Tube

NOTE: An O-ring inside the quick connector

provides the seal between the quick

connector and the port. Be careful not to

damage the mating surfaces and O-ring

when attaching the connector. Do not allow

foreign material to enter the connector or the

port.

Do not expose the assembly to battery electrolyte or do

not wipe the assembly with a cloth used to wipe off spilt

battery electrolyte.

Piping that has been splattered with battery electrolyte or

battery electrolyte soaked cloth that was wiped on the

piping cannot be used.

Removal

1. Open the fuel cap to relieve the fuel pressure in the

tank.

Use compressed air to remove any dirt on the fuel

quick connect fittings prior to disconnecting the

fittings.

141R100002

When disconnecting the fuel pipe, cover the area with

a cloth to prevent fuel from splashing as the fuel pipe

may still have some pressure in it.

2. For removal of the quick connector, pull out the

connector with the other hand while pressing the

square relieve button of the connector, as illustrated.

140R200001