Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 233

6C–12

ENGINE FUEL (6VE1 3.5L)

Fuel Gauge Unit

Removal and Installation

Refer to “Fuel Pump” in this section for removal and

installation of the Fuel Gauge Unit, since the fuel gauge

unit is linked to the fuel pump and sender assembly.

Fuel Filler Cap

General Description

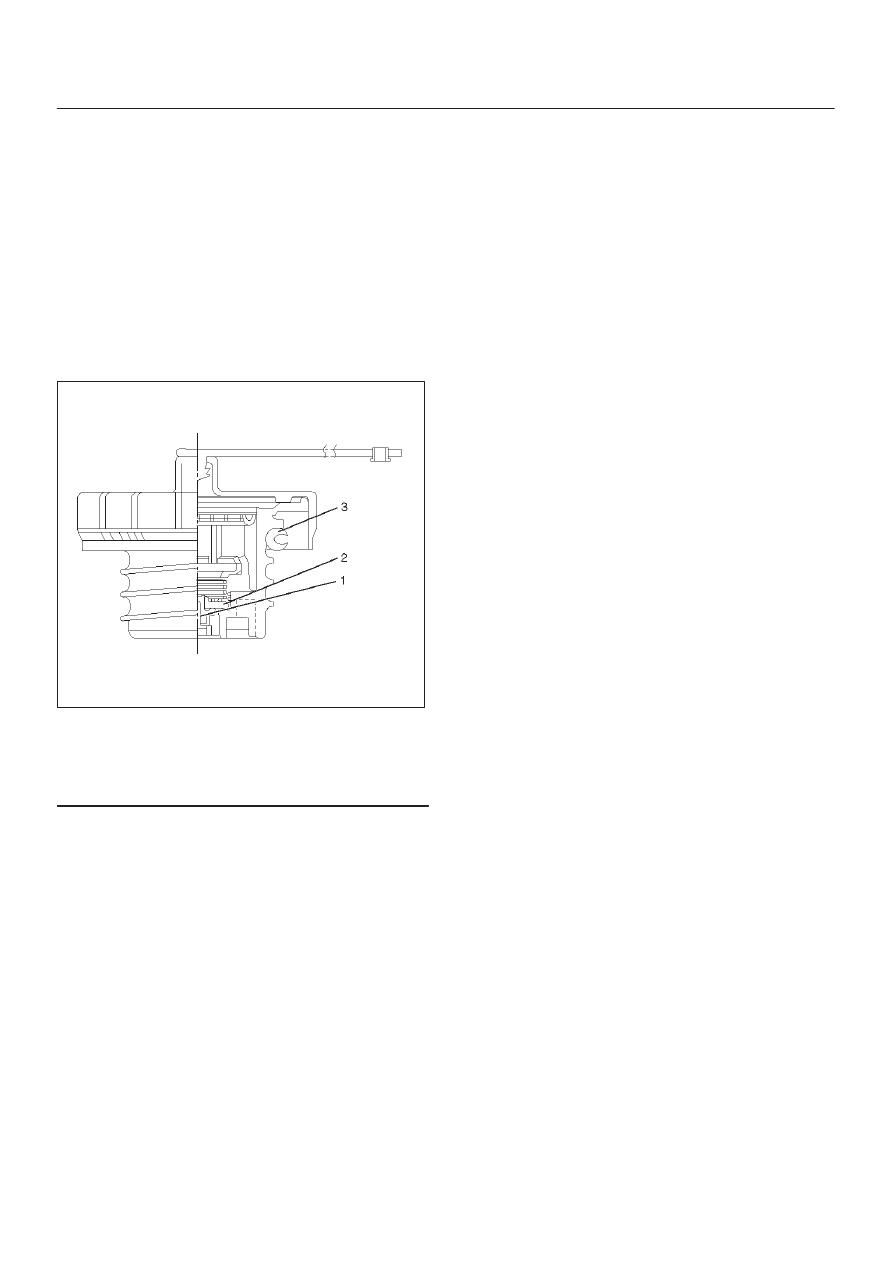

A vacuum valve and pressure valve are built into the fuel

filler cap which adjusts the fuel pressure in the fuel tank to

prevent fuel tank damage.

140R100029

Legend

(1) Vacuum Valve

(2) Pressure Valve

(3) Seal Ring

Inspection

The fuel filler cap must be inspected for seal condition.

The fuel filler cap must be replaced if found defective.

CAUTION:

A replacement fuel filler cap must be the same as the

original. The fuel filler cap valve was designed pri-

marily for this application and must be replaced with

the same type or decreased engine performance may

occur.