Great Wall Hover. Manual - part 57

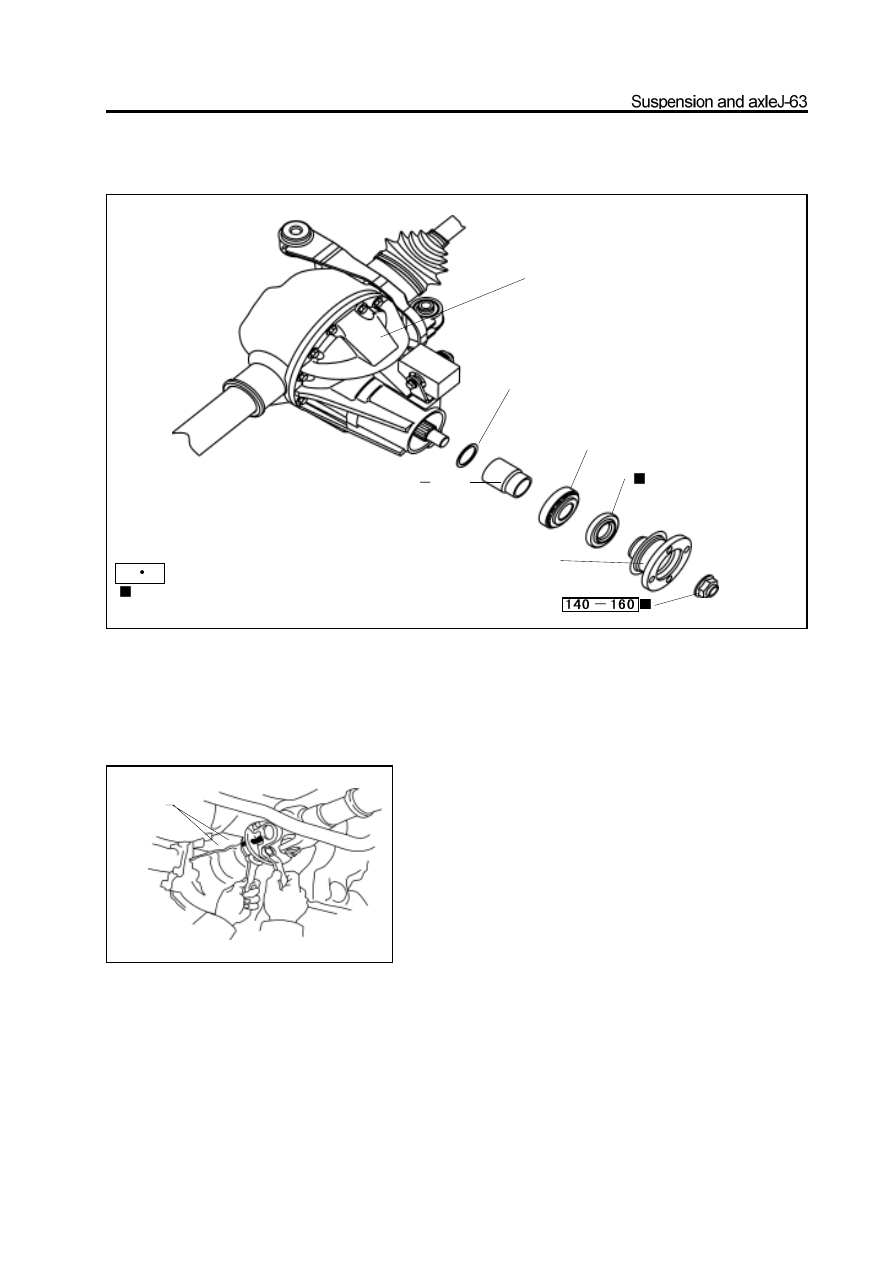

Replacement of drive gear oil seal of front reducer assembly

1. Support the front of car; remove the left and right

front wheel and the beam under the reducer.

2. Drain the lubricant oil in the front reducer; remove

the left and right steering knuckle

3. Disconnect the front reducer assembly flange from

the drive shaft and use the jack to remove the front

drive axle

Caution: Make the assembly mark on the reducer and

drive shaft before separate them.

4. Remove the front differential assembly

(Caution: Drain the oil in front differential before the

disassembly)

front reducer

assembly

washer

spacer

drive

bevel gear

bearing

oil seal

front reducer drive gear flange,

main gear flange and dustproof

cover assembly

Used component which can not be used

any more.

N

m:

specified torque

assembly mark