Great Wall Hover. Manual - part 55

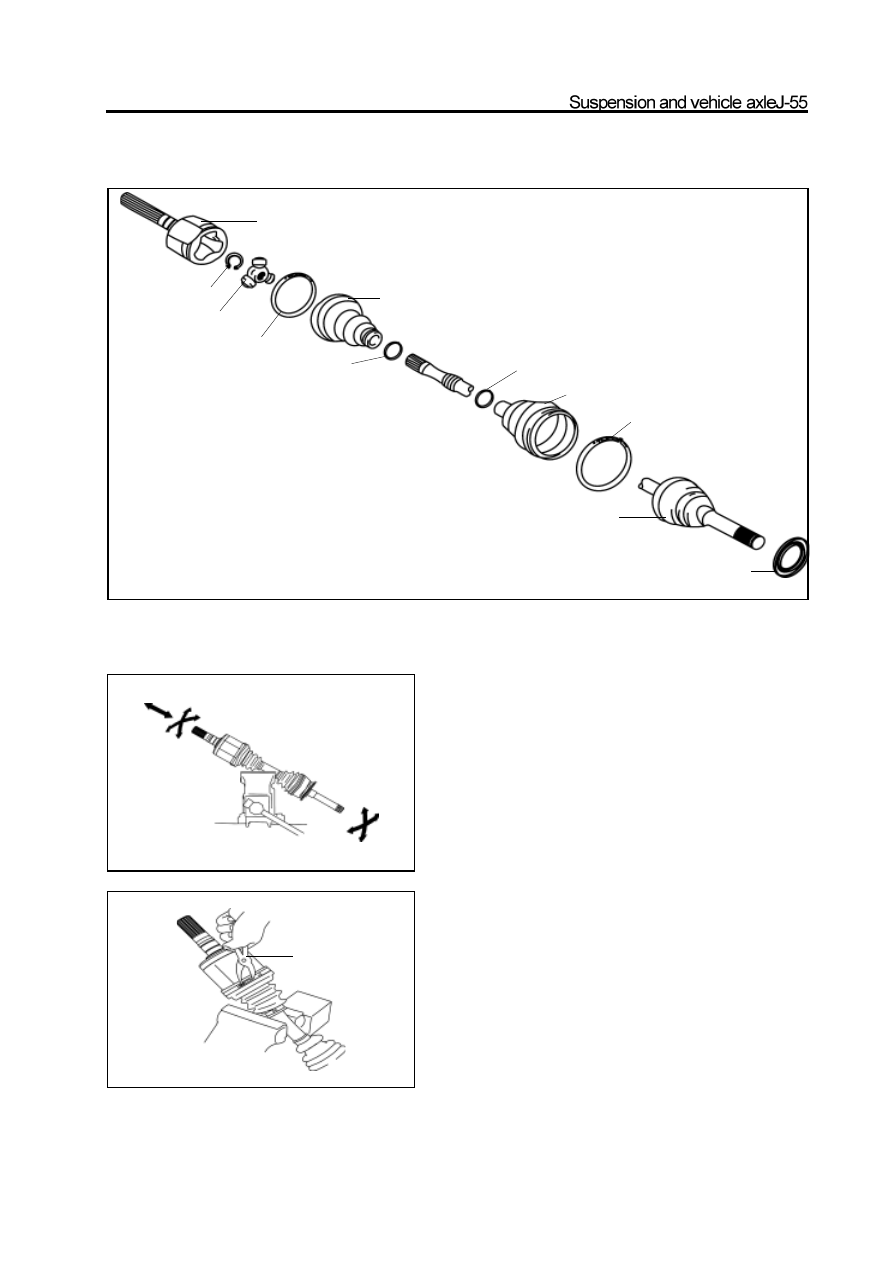

Constant-speed drive shaft assembly

pliers

Disassembly of constant-speed drive shaft

assembly

1. Check the front drive shaft assembly

a. Check the inner trumpet connector; it could slide in axial

direction smoothly.

b. Check the universal-joint position; it should be without the

clear clearance in radius direction.

c. Check the inner and outer jacket for damage.

Caution: It should use the pad when clamp the front drive

shaft to avoid the damage of it.

2. Remove the large clip of inner jacket

Caution: Do not damage the inner and outer jacket

inner trumpet connector

circlip

three-pin section assembly

large clip of inner jacket

inner jacket

small clip of inner jacket

small clip of outer jacket

outer jacket

large clip of outer jacket

outer trumpet connector

dustproof cover