Great Wall Hover. Manual - part 56

6

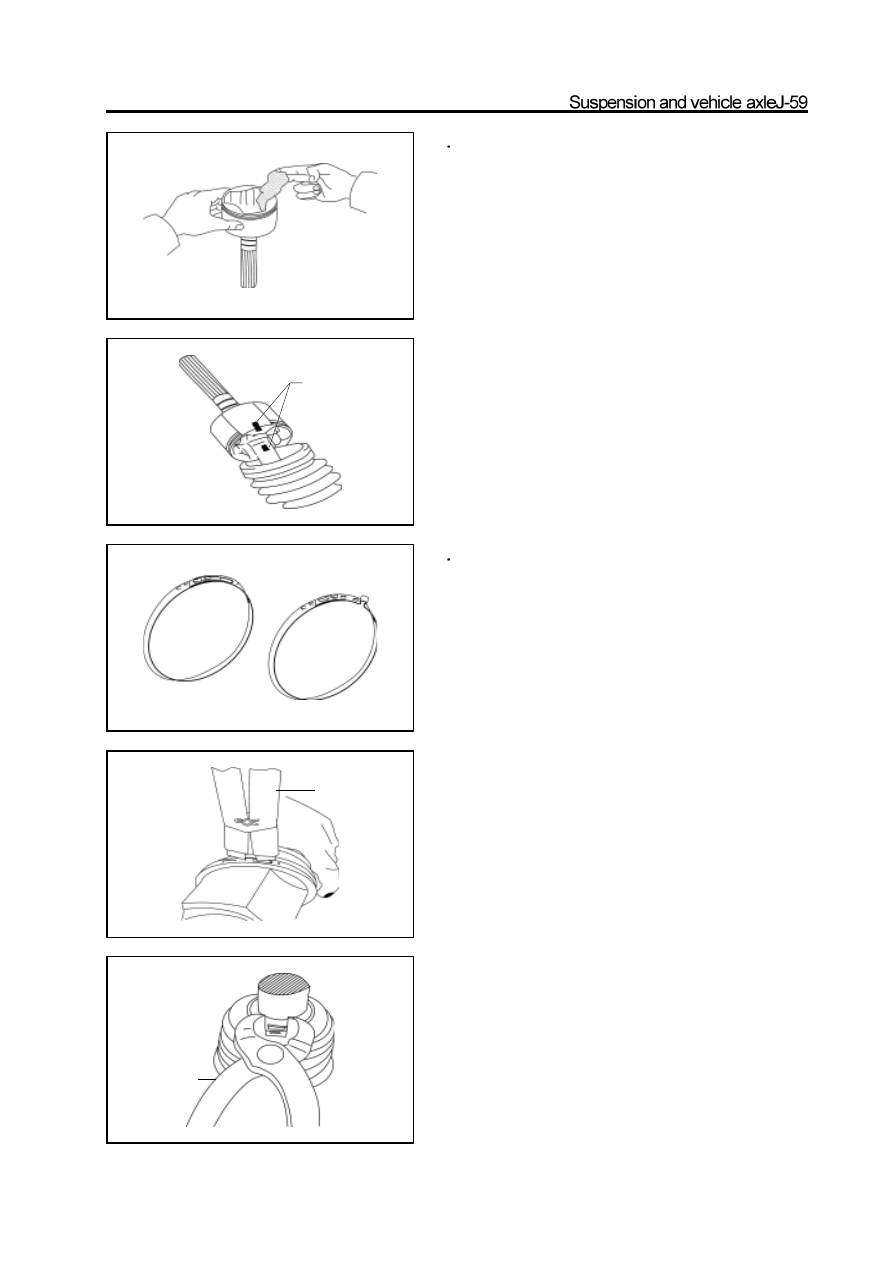

Install the inner trumpet connector on the front

drive shaft

a. Fill the inner trumpet connector and inner jacket with the

grease supplied with the jacket

(Recommend used grease is CAPLEX or KY1). Amount About140g

b. Align the assembly mark made during disassembly; covered

with inner trumpet connector.

c. Cover the inner jacket on the inner trumpet connector.

7

Use the inner and outer jacket clip pliers to

clamp the inner and outer jacket.

a. Use the special non-ear clip pliers to lock the large clip of

inner jacket.

b. Use the nutcracker to lock the small clip of inner jacket.

Caution: Ensure the large and small connecting place of jacket

is in the corresponding groove of trumpet connector and shaft.

assembly mark

outer jacket clip

inner jacket clip

non-ear clip pliers

nutcracker