Great Wall Hover. Manual - part 54

Stabilizer bar

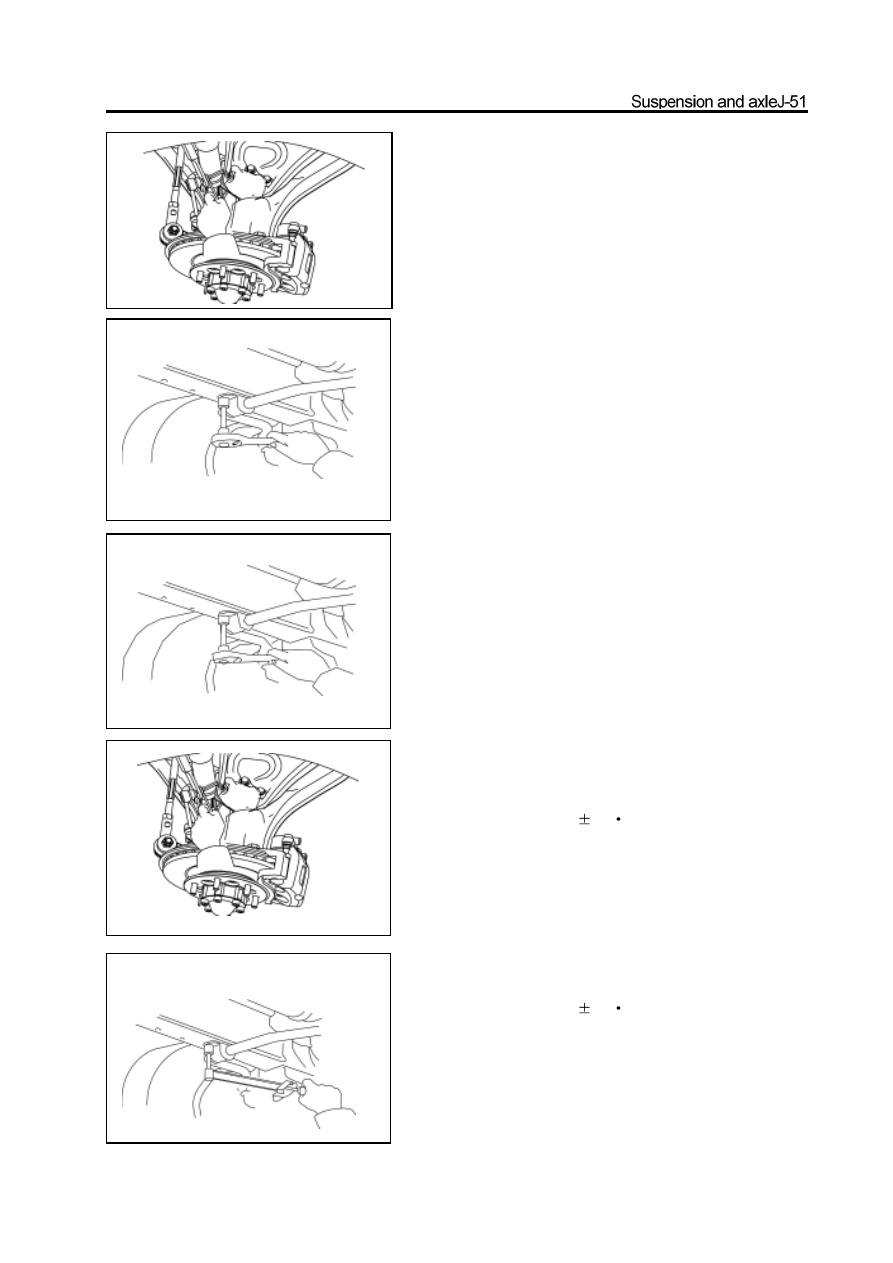

Disassembly of stabilizer bar

1. Disconnect the connecting bar which supports both

ends of the stabilizer bar form the stabilizer bar.

Use the inner hexagon spanner to fix the ball pin; remove the self-

locking nut.

2. Remove the bush and clip of stabilizer bar; remove

the stabilizer bar

Installation of stabilizer bar

1. Install the stabilizer bar on the carriage

Place the stabilizer bar in position; install the stabilizer bar bush and

clip on the carriage. Align the mark on the stabilizer bar to keep the

left and right gap of stabilizer bar are same. Then install the bolt

temporarily and pretighten it.

2. Connect the stabilizer bar to the connecting rod.

Install and tighten the new nut to the specified torque.

Tightening force: 63

5N

m

3. Tighten the clip position bolt to specified torque.

Tightening force: 23

2N

m